Tracking Precast Concrete Elements

Tracking Precast Concrete Elements from the initial design stage, through the production and out to the construction site is a major challenge for many Precast Companies.

Structural precast is a complex and multi-skilled business, not least because it’s a bespoke product competing against traditional on-site methods of construction. This places huge time pressures on precast businesses; to prepare 3D conceptual designs, calculate accurate costs and delivery schedules. The demands on design, production, and project management resources are considerable.

All this activity is compounded by the time and effort it takes to report to Management with data that is often in silos. Project Managers are spending too much time managing spreadsheets rather than managing the projects.

What if you could do away with spreadsheets, reduce time trying to find information, reduce errors from manually moving from one system to another and spend more time actually managing your precast projects?

Integration of design, production, and project management are key to Tracking Precast Concrete Elements

What we see from StruSoft’s perspective is that wrapped up in these three key areas of precast is a myriad of systems, processes, and workflows. Precast IT systems and processes have tended to evolve with small incremental improvements over time. With the rise of CAD, 3D modelling software and the Digital Age, it makes sense for precast businesses to address their design processes first.

Design is a key part of the process, of course. But are you able to make the most of your resources (software, personnel, time, and plant) without combining your production, project management and all the associated data into one IT system?

The speed of reaction, communication, collaboration, control over logistics, the flow of information and integration between these three areas are paramount to the success of your precast projects.

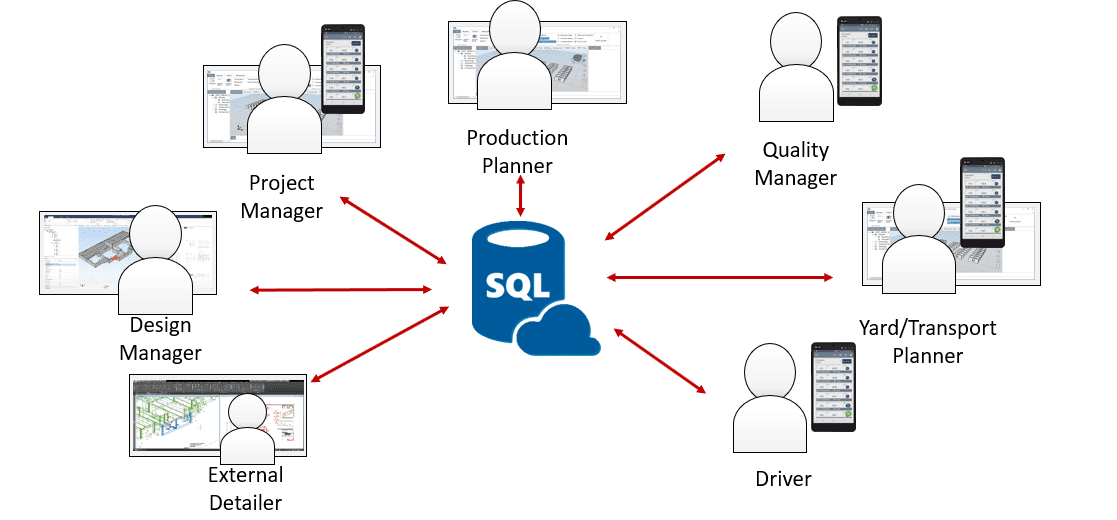

What if you could connect all Stakeholders to the same data set to improve the communication and collaboration on your projects with real-time relevancy?

The IMPACT SQL database is a single south of truth for your entire precast business with real-time relevancy

IMPACT is a fully integrated system that allows you to streamline all your design, production and project processes into one controlled real-time dataset.

Together with the IMPACT Status Machine, Element Controls, QR Codes, Labels & Reports, the various software interfaces and IMPACT Go mobile application allow you to keep track of every single precast element at any stage of the design, production or project processes.

Advancements with Mobile and Cloud computing mean that you are now able to access your IMPACT precast project data and makes tracking precast concrete elements possible from anywhere and on any device.

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Blog

BIM in the Precast factory. To digitalize the process and the business, Helgeland Beton is using IMPACT

Get an insight into how Helgeland Beton is taking care of its precast business and the processes behind it – through digitalizing with IMPACT.

IMPACT User Conference 2022 – Live stream of the event (Live from Malmö)

Tomorrow, we are hosting our annual IMPACT User Conference – Live from Malmö. We celebrate that this year, IMPACT […]

30th Anniversary of IMPACT: At the forefront of digitalizing the Precast Concrete Industry

This year, IMPACT turns 30 years old. Our flagship software to allow a cohesive flow of information in the precast concrete industry […]