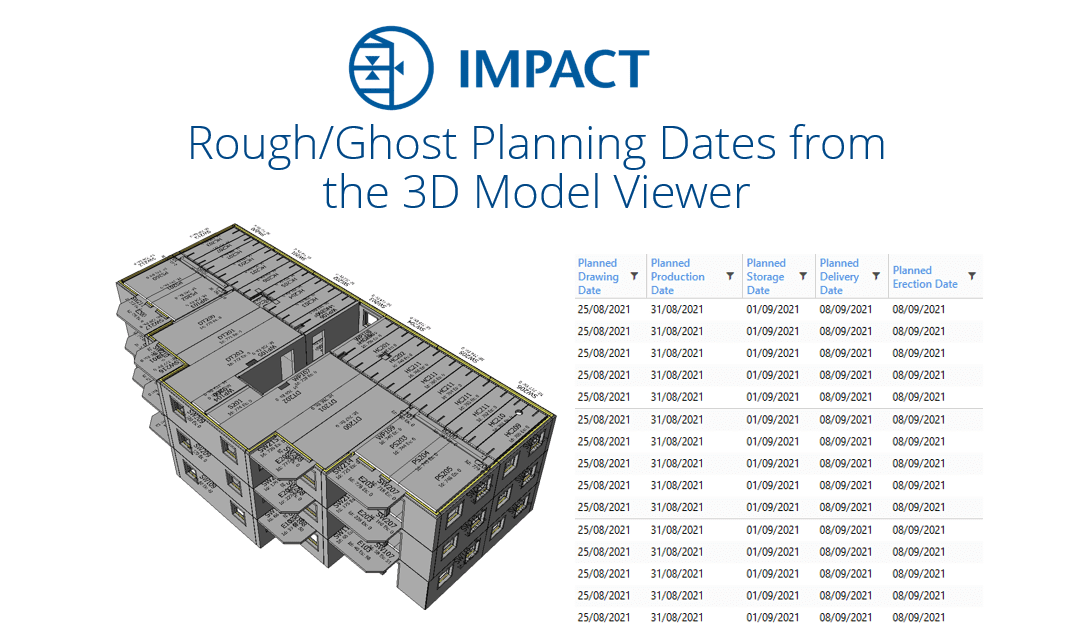

Precast Rough/Ghost Planning

Watch the Precast Rough/Ghost Planning Video

Rough/Ghost Planning is the first step when a Precast Project has got the go ahead. It’s quite a straight forward step for Project Managers to set some initial target dates for all aspects of the project, production and design processes.

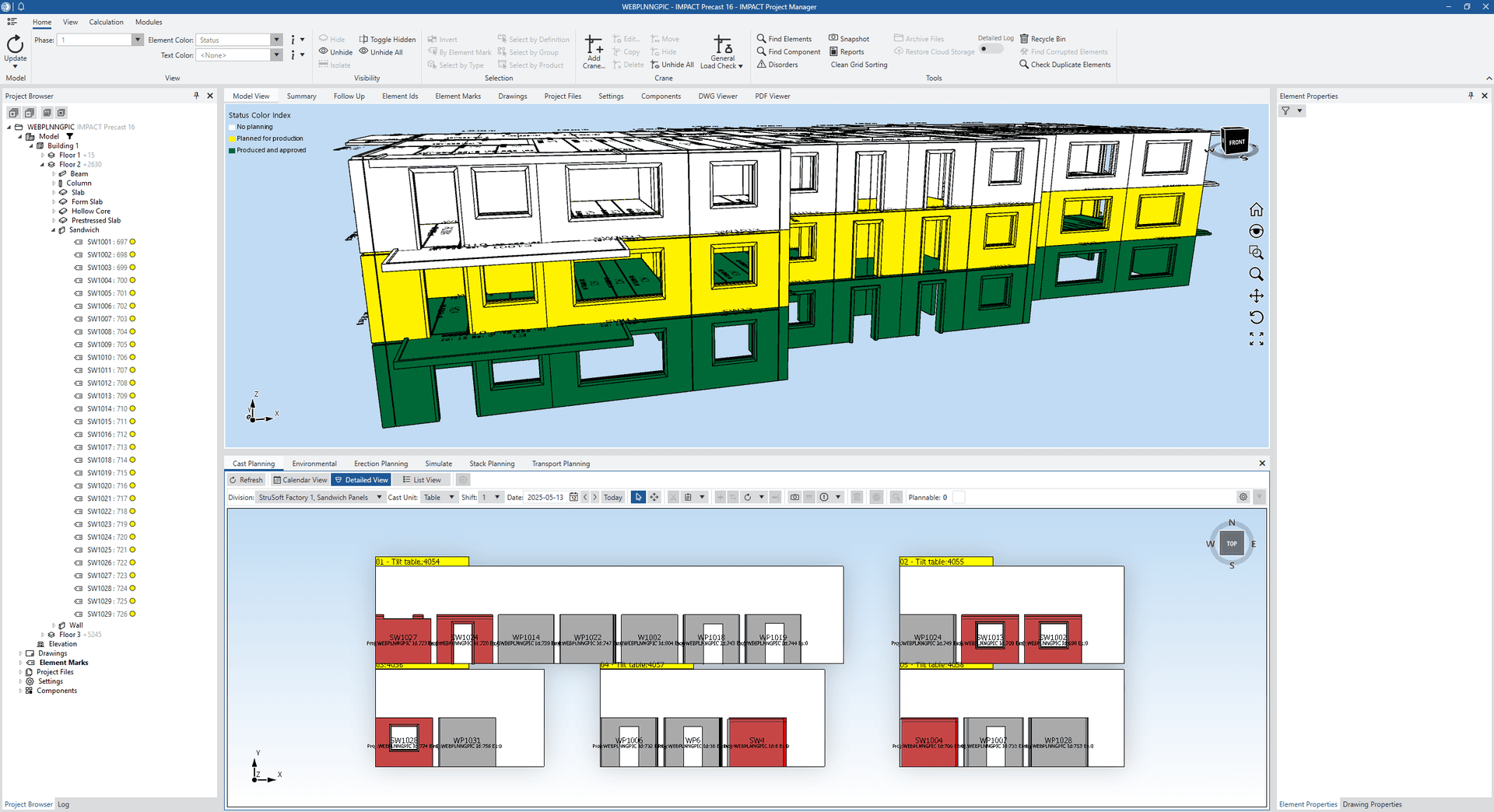

You can work through either the IMPACT Project Manager with the 3D Model as reference or work through the IMPACT Resource Manager to rough/ghost plan on all Precast Element Types in the Project, using set start or end dates.

If used together with the Erection Planning module, the rough planning date logic will know the order of erection, daily capacity of erection and even which cranes can erect which elements. After rough planning, you will be waiting then for shop drawings to be able to actually detail plan the element casting, stacks and transportation etc.

Precast Rough/Ghost Planning Date Dependencies

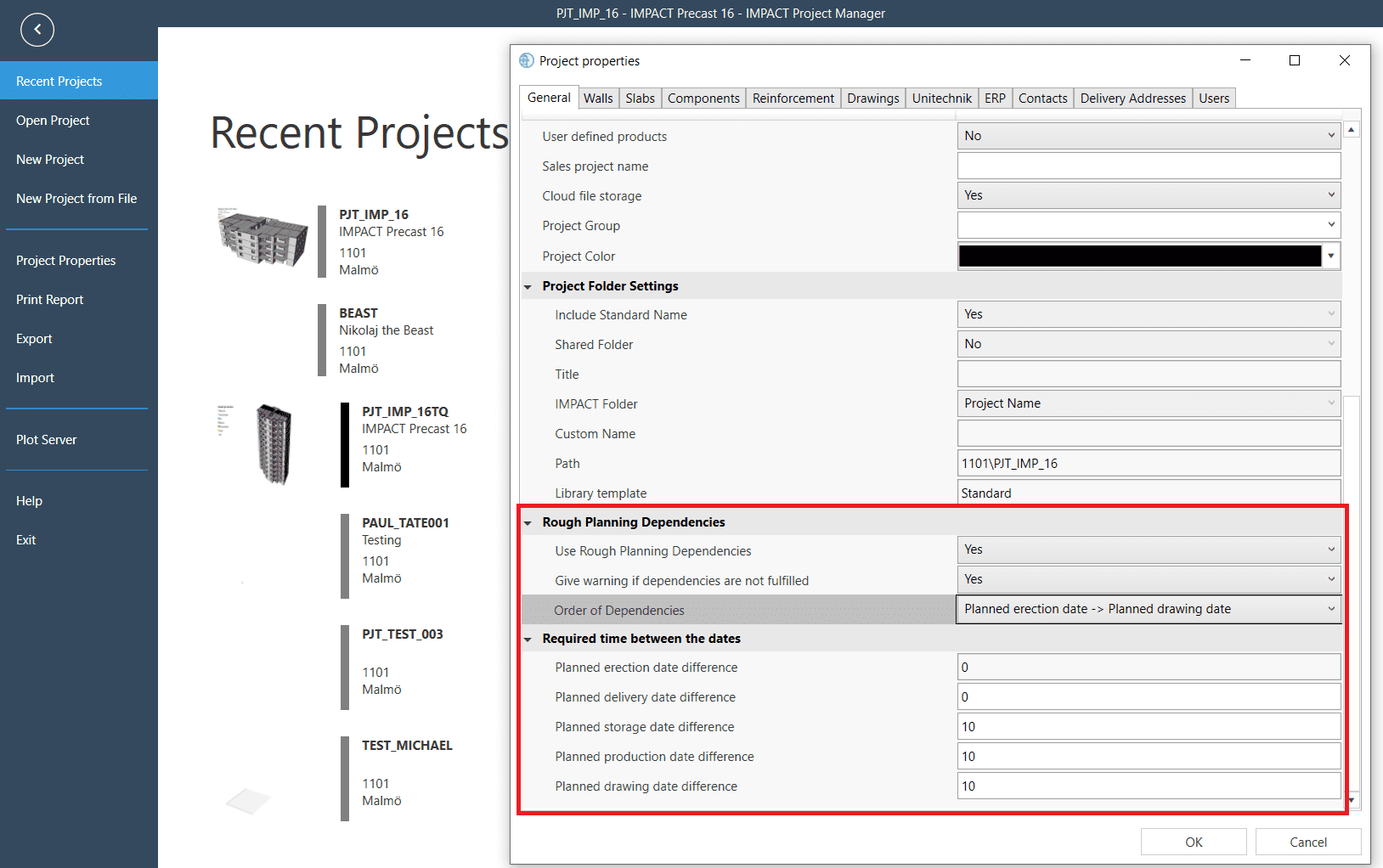

In the latest v16 of IMPACT there is a new feature to speed up your Rough/Ghost planning. In the Project Properties there is a new setting called “Rough Planning Dependencies” which allows you to set the required date requirement between key Rough/Ghost planning dates.

You choose whether to plan backwards from the erection sequence or you can plan forwards from the drawing date. You can set up time factors between the erection date, delivery date, storage date, production date and drawing date for all the precast elements in your project.

Once this has been set up then you just select a rough planning date once and then IMPACT brings the automation to apply all the date dependencies throughout the phases and every Stakeholder in the process gets visibility on the rough planning dates.

You can read more about this new Precast Rough/Ghost Planning Date Dependencies feature on the IMPACT Wiki by clicking here.

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Blog

From Planning to Transport: See How IMPACT Streamlines Precast Production

Looking to streamline your precast concrete workflow? In our recent webinar, “Precast Production Planning in IMPACT,” we demonstrated how the IMPACT platform simplifies and accelerates […]

Struggling with planning precast projects in Excel?

With the rise of digitisation; advancements in BIM, many precast businesses have moved to 3D design of their precast concrete projects. However, many factories and […]

IMPACT Environmental: Future-Proof Your Precast Concrete

Streamline Sustainability Compliance with IMPACT Environmental

The construction industry is facing a wave of new sustainability regulations, with stricter Life Cycle Assessment (LCA) […]