IMPACT Reinforcement Detailing Software – RC Detailing

Watch the IMPACT Reinforcement Detailing Software Video

Are you an RC detailer? then you are in the right place. Read more about IMPACT Reinforcement below.

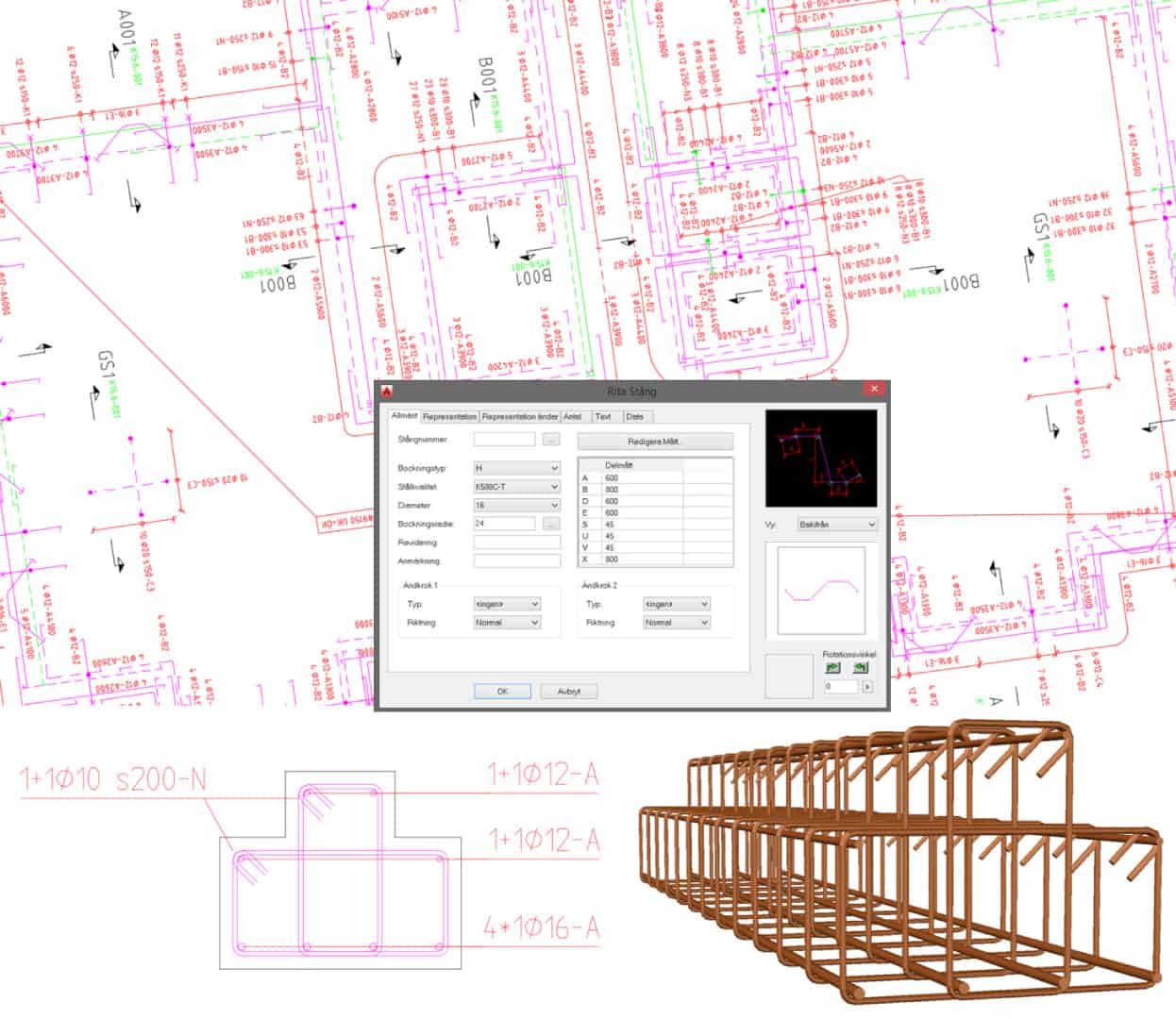

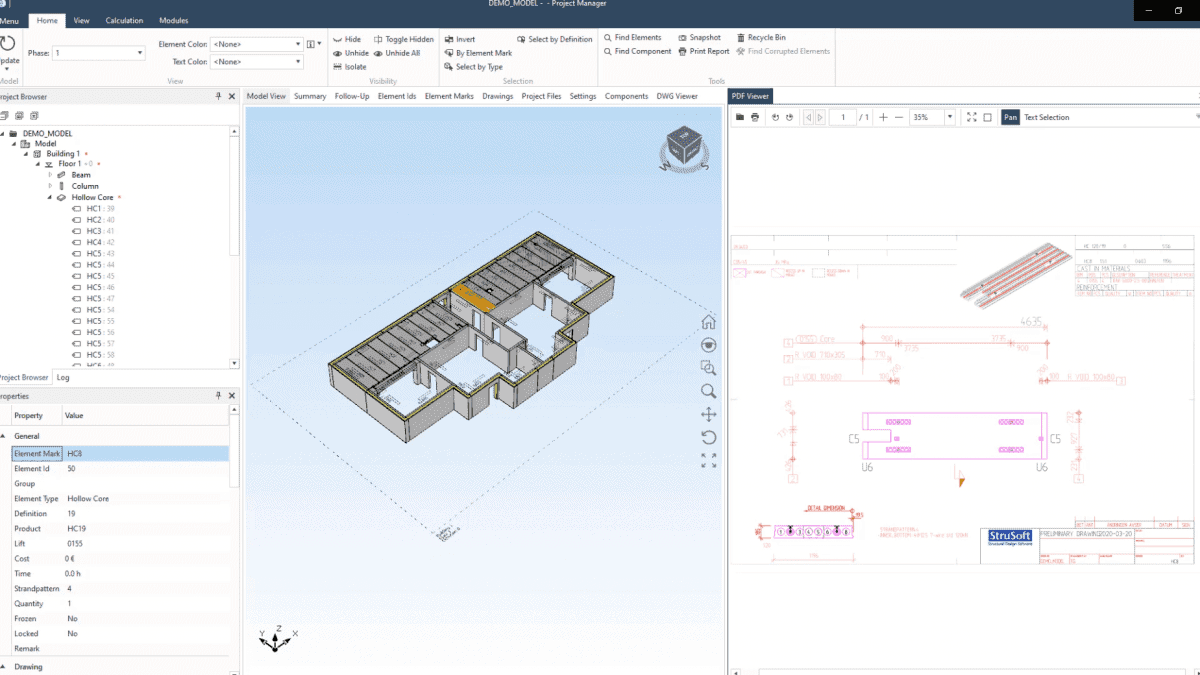

IMPACT Reinforcement lets you detail intelligent models, drawings, and schedules. You can quickly install, and start on your RC detailing journey today, as it is a plugin application for AutoCAD and BricsCAD.

You can use IMPACT Reinforcement as standalone software or together with our IMPACT Design precast detailing software.

When you use IMPACT RC together with our IMPACT Design modules, it opens up automatic reinforcement templates, groups, and schedules for any type of precast element. It even creates exports to machine-readable files (Unitechnik, BVBS, PXML, and more).

Why should you use our IMPACT Reinforcement Detailing Software?

Speed up your detailing

Use the objects in our IMPACT RC detailing software in order to greatly speed up your detailing process. You can define your rebar including bar mark, shape code, leg lengths, end hooks, and material. Depending on view direction and bar settings, the bars can be shown as easily-read symbols according to standard, but can also be displayed as 3D solids. – Whatever you prefer!

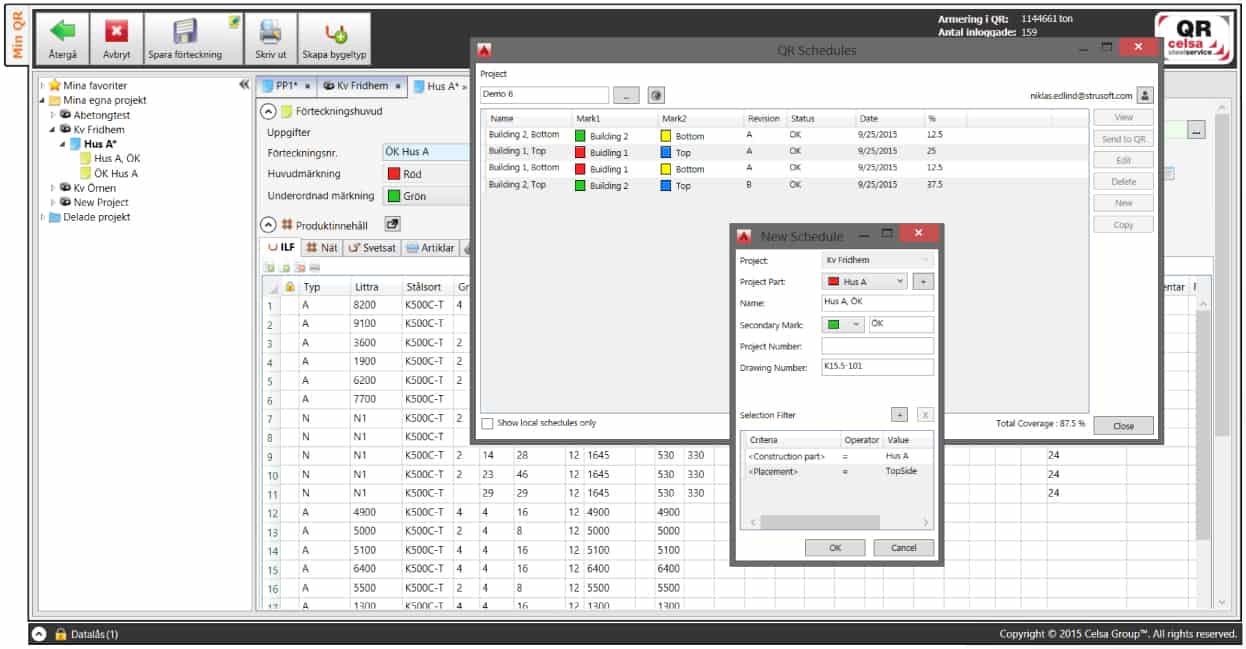

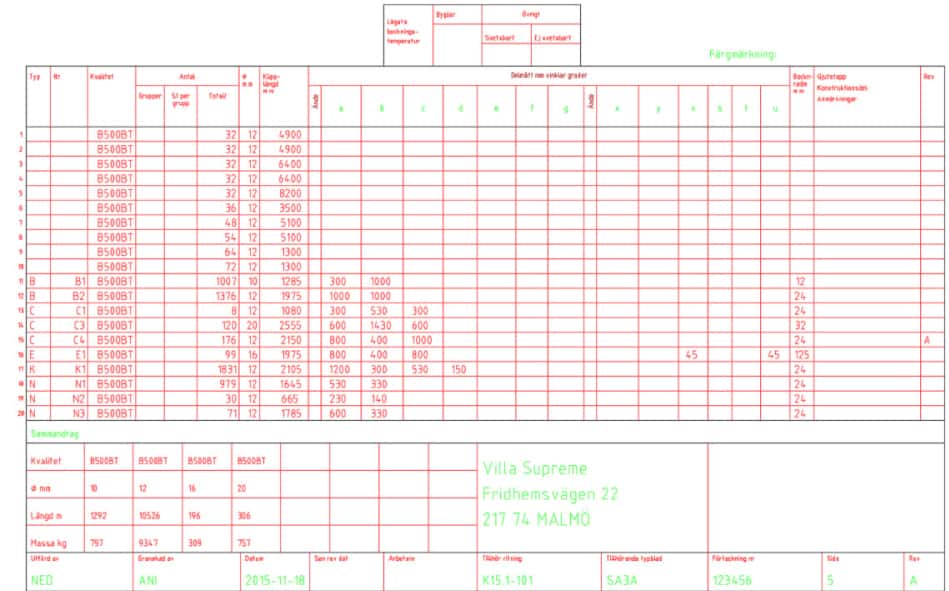

Save time with automated scheduling

With rebar defined as smart objects, schedules can be created with the push of a button. Customize your layout and extract data with company standards. Multiple DWG files can even be connected to share bar mark definitions and allow for common scheduling across several drawings. Even for large projects, schedules can easily be filtered on any bar data, such as the construction part or cast phase for easier call-off.

Stay connected to your machinery

It is surprisingly easy to connect to machinery, IMPACT Reinforcement automatically creates machine-readable files, for instance, BVBS, PXML, and more.

Tailored to fit your company

You can adapt most objects in the IMPACT RC software to your own preferences or company standards. End marks, end hooks, shape codes, rebar text, materials with bar diameters, schedule layout, and data can all be modified, just to name a few.

Last but not least?

- Automatically calculate quantities from distribution lines and spacing

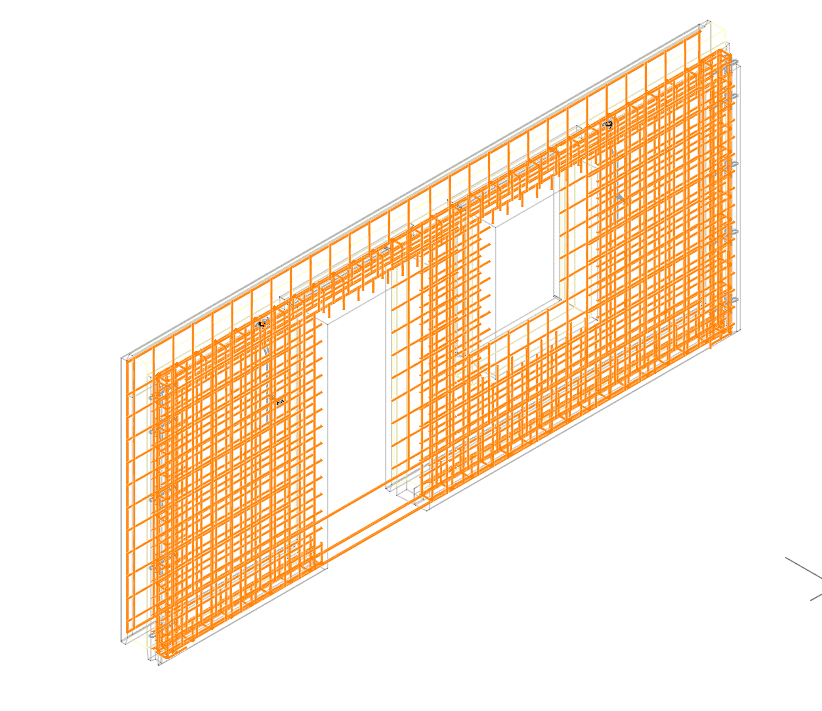

- Use the drawing tools like bars from polyline and surface reinforcement to make your rebar drafting quick and easy.

- Handle variable leg lengths and running length bars

- Easily export your data: export to XML and BVBS or save directly to the Celsa Steel services QR web schedule service

- Model and schedule rebar

- Easily read symbolic representations according to standard or 3D solid graphics based on your needs

- Find all the necessary information you need to define rebar including bar mark, shape code, leg lengths, end hooks, and material

- Finish your rebar drafting jobs quickly using drawing tools such as bars from polyline and surface reinforcement

- Furthermore, you can use it in conjunction with any of our IMPACT Design modules, to open up automatic reinforcement templates, groups, and schedules for precast elements

IMPACT Wiki

Last, but not least, you can find full technical details and the theory behind our IMPACT Reinforcement Detailing software on our IMPACT Wiki by clicking here.

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Blog

BIM in the Precast factory. To digitalize the process and the business, Helgeland Beton is using IMPACT

Get an insight into how Helgeland Beton is taking care of its precast business and the processes behind it – through digitalizing with IMPACT.

Can I save 20-90% on Precast Detailing time, and even get 3D models and BIM at the same time? (Yes you can)

BIM doesn’t have to be slow

10 years ago, in 2012 I was doing a master’s thesis on the use of IT systems in the […]

A competitive CAD alternative to work with IMPACT Design

Since 2018 IMPACT Precast Design and IMPACT Reinforcement have been fully integrated and compatible with BricsCAD. Here are five great reasons why you might now want […]