This year, IMPACT turns 30 years old. Our flagship software to allow a cohesive flow of information in the precast concrete industry comes from a dedicated team of design engineers with a great interest in technology – As true then as it is now. In this article, we talk about IMPACT’s fantastic story that begins in an analog environment where the designers worked on the drawing board with a pencil. Then came AutoCAD, and everything changed.

At Skanska, a need arose during the 1990s to facilitate more efficient production of precast concrete elements for the ten concrete factories they then had. There was a desire to ensure the quality of the information chain, from design, production, and out to construction. To streamline the design with uniform and standardized drawings and improve the design work. At that time, there was no specific software available to buy, and for that reason, they took matters into their own hands and started their own in-house program development.

– “It was an innovative spirit that prevailed at Skanska with visionary leaders who saw the opportunities and benefits of digital technology,” says Håkan Hansson at StruSoft.

Skanska also had its own software development company, Skanska Software, which was founded in the early 1980s. Håkan was one of the pioneers and wrote the first code in IMPACT, and he has been involved ever since and is today Technical Senior Advisor at StruSoft, after many years of being at the forefront of the industry.

IMPACT 1.0 saw the light of day

The project group was appointed, and among others, Håkan participated, and also Paul Rehn, who later became the CEO of StruSoft. The first result of the group’s work was to apply the software idea to a type of element that was most common, and they chose hollow-core slabs. It characterized the first version, IMPACT 1.0, and contained several features, including automatic drawing generation, automated plotting, and a symbol library that would replace the search in the Technical Binder.

The pace of development in the project group was high, and at the same time, as the first version of IMPACT was released, a new project was announced in the form of a floor plan manager for beams. The group’s ambition was to produce a basis for all element types, but at the same time, new ideas were born that are now well-known brands in StruSoft’s program family, such as FEM-Design.

The Users participated in the development from the start

The get the best possible software, it was decided very early in the process to involve the end Users as much as possible.

– We had reference groups where the designers got to be involved and liked it, Håkan remembers. It gave a positive atmosphere when we listened to the Users who helped solve problems and challenges.

It was at least as important for the project team to understand the Users at the factory, those who would receive the information, and from the larger perspective, understand the entire information chain. It was all about considering the Users’ suggestions and experience of IMPACT to make the program more productive and innovative – this still applies today.

One of the first designers to work with IMPACT was Ruben Gianolio, who worked at Skanska Prefab, a subsidiary of the holding company. He carried out one of the first projects and designed a steel frame with precast hollow core slabs – used in a construction project for IKEA in Helsingborg.

Goodbye easel, welcome smarter digital technology

– It was a very innovative time! Ruben remembers. It was both different and exciting to work with computers instead of standing at the easel, drawing by hand with a pencil, and erasing and cutting in the manifold paper if it went wrong. Of course, the drawings now became much more accurate and uniform.

At that time, Ruben and his colleagues in the industry worked at a large drawing table – the so-called easel. This analog way of doing things was replaced by digital technology in this innovative period, and it changed Ruben’s work forever.

– I worked a lot by hand and copied drawings on the easel, but everything changed when I went into the digital world. Back then, the program retrieved information from a database, such as length, width, holes, and other properties – and the program automatically drew the element without me having to do it myself.

Safer and more reliable information flow to the factory

An entirely new way of detailing emerged that saved lead time and gave a much more reliable result because there was no need to interpret handwritten letters and numbers. This information became even more reliable as the drawings became increasingly standardized, this happened through a dialogue with the precast concrete factories to accommodate the optimal process and flow. Ruben saved a lot of time as the data flow became more efficient and transparent in each step.

– “It was fantastic to be part of this digital journey. I was also part of the reference group and gave opinions, not only to improve my work as a designer – but also for the whole process.

Gradually, IMPACT’s capacity was broadened and deepened. New functions were added to meet the vision that Skanska had to produce a coherent information flow – for example, with assembly and transport. Always in a creative dialogue with the users and the concrete factories.

At the same time, the program was ready to be launched on the open market and was no longer a matter for Skanska Prefab. It was the start of StruSoft, which was spun off through a Management buyout in 2002 to give the construction industry a content-rich portfolio of advanced software programs systems. Not only in Sweden but also internationally. In addition to IMPACT, both WIN-Statik and FEM-Design – were added to the portfolio of solutions by StruSoft.

Coordinated data flow from different systems in the next generation of IMPACT

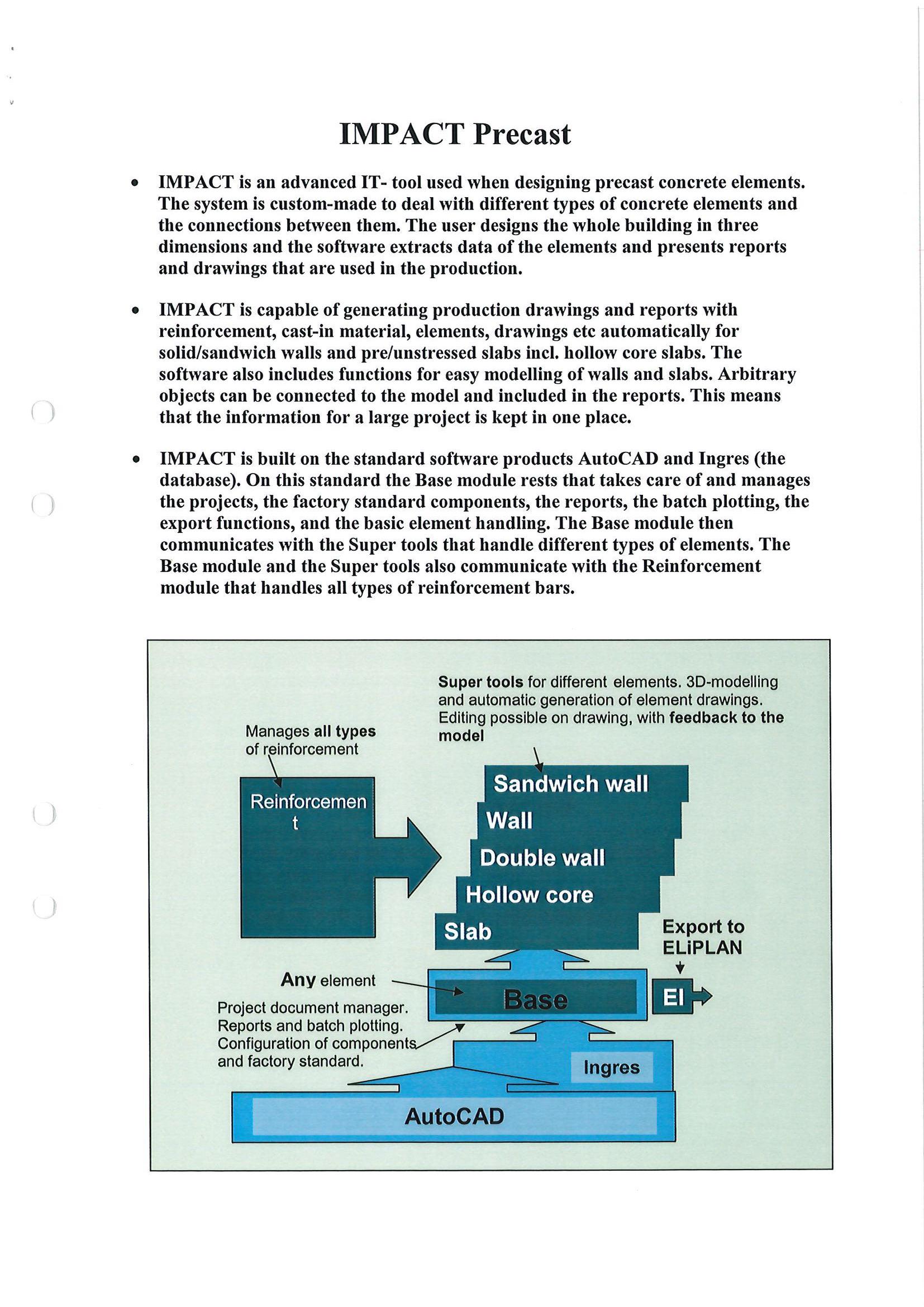

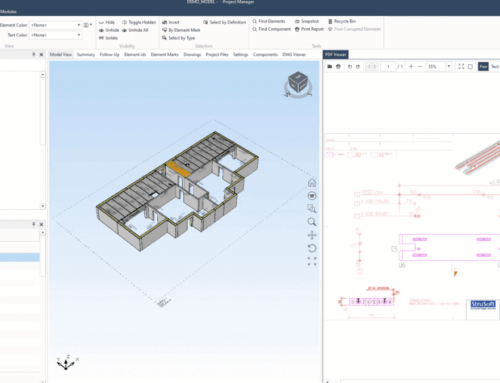

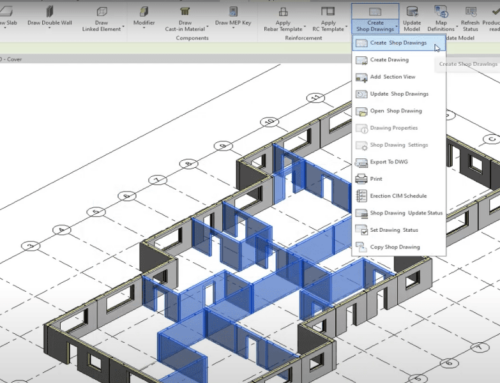

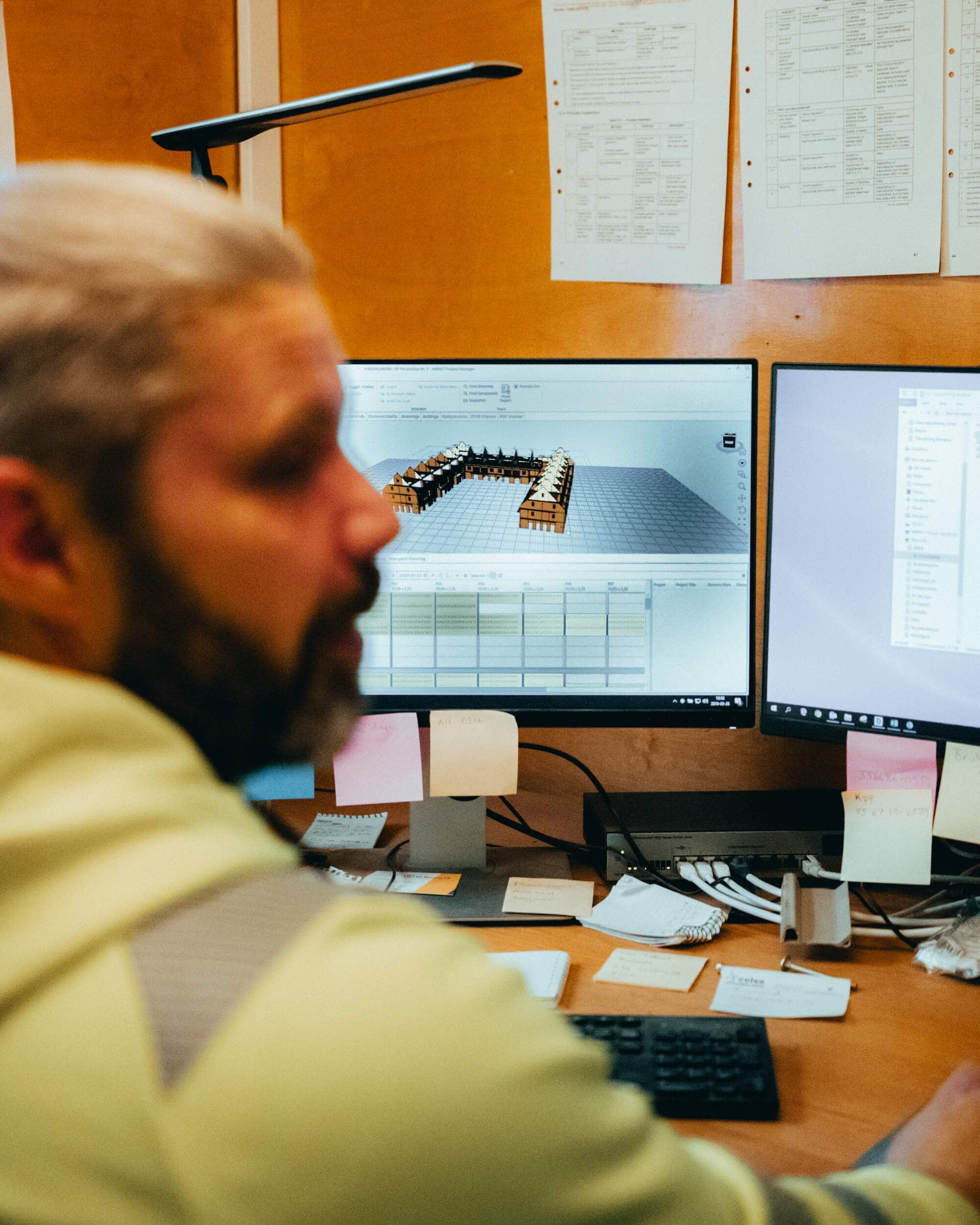

The development of tomorrow’s IMPACT is constantly ongoing in the same innovative spirit as it had from the beginning. Today, it revolves around further strengthening the flow of information, which was one of the original ideas behind the program. Peter Karlsson, who is a department manager within IMPACT’s business area, points to the need to get a thorough data flow from various systems that increase customer quality in the production chain.

– “It’s not just about being able to use different systems such as AutoCAD, Revit, and Tekla and that the customer can streamline their process with an API for IMPACT,” says Peter. We have a much broader view than that – Finance is an important area where we see opportunities to include, for example, stock balances on materials so that IMPACT provides a clearer overall picture of the entire process. Another possibility is to connect areas of expertise.

– The consultant has his field of knowledge, and the staff at the concrete factory has his. IMPACT becomes a tool to ensure the data flow, and together with all other data – is included in the same process.

In this period of thirty years, a very rapid change has happened as the construction industry has become digitalized.

During this time, StruSoft has played an important role in meeting the growing need for innovative solutions – and will continue to do so. The reason is obvious because StruSoft, IMPACT, and the other software systems come from the industry itself, from design engineers with a great interest in technology.

The article was written by Love Jansson / Translated and finalized by Mathias Hansen and Nikolaj Stephansen

Would you like to learn more about IMPACT software and perhaps be interested in receiving a free demo and consultation on how we can support your Precast business? Then don’t hesitate to Book a 1:1 Teams meeting with one of our IMPACT representatives – they will be happy to help you. Or you can follow the form below to Book a Demo.