The construction industry is witnessing a significant shift towards precast concrete solutions due to their numerous advantages, including improved quality, reduced construction time, and enhanced durability. In Ireland, the demand for precast construction has been steadily increasing, leading to the emergence of innovative technologies that optimize the design, production, and project management processes. StruSoft’s IMPACT Precast Software has emerged as a game-changer in this domain, revolutionizing the way precast projects are executed. In this blog post, we will explore a remarkable case study of a precast builder in Ireland that leveraged the power of IMPACT to achieve unparalleled success.

Precast Builder in Ireland

Introduction

The precast builder Hi Therm Homes (HTH) in question was facing several challenges common in the construction industry, including lengthy project schedules, coordination difficulties, and the need to maintain stringent quality standards. To overcome these hurdles, they turned to StruSoft’s IMPACT Precast Software, a comprehensive software solution designed to streamline the entire precast construction process. HTH restarted their precast factory after a long gap in operations and this was when the housing market in Ireland was witnessing a good surge in demand. HTH wanted to make the most of this opportunity and having their own precast manufacturing setup offered them a good head start.

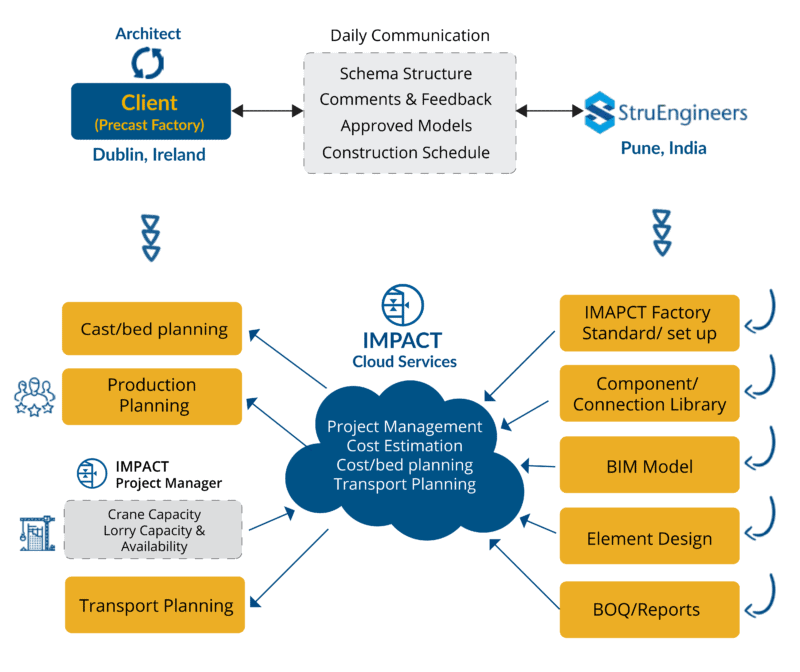

To reduce turnaround time and improve efficiency, they decided to digitalize the complete manufacturing process and for this, IMPACT’s BIM solution came up as a natural choice. HTH does not have an in-house team for designing precast elements. As time was of essence, they did not want to go through the hassle of hiring new employees & training them and outsourced the precast elements design work to StruEngineers – a subsidiary of StruSoft, offers expert precast design and detailing services with 40+ years of experience.

The Setup

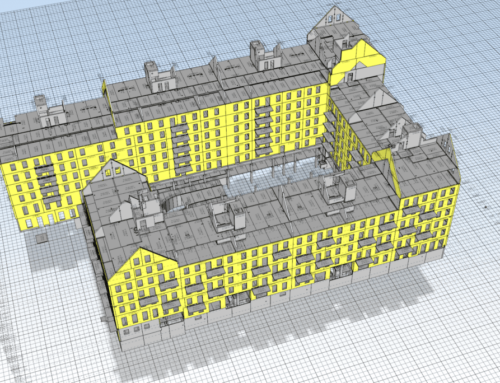

HTH, lacking BIM software at the beginning, took the initiative to collaborate with StruEngineers by sharing architectural drawings. Through several rounds of discussions, HTH eventually shared the final approved model and construction schedule. Subsequently, HTH proceeded with the establishment of the Standard IMPACT BIM factory setup, encompassing the creation of a comprehensive component and connections library. This foundation would serve as a solid framework for both ongoing and forthcoming projects. Next, the design of precast elements took place, followed by the preparation and sharing of the final Bill of Quantities (BOQ) and reports with HTH.

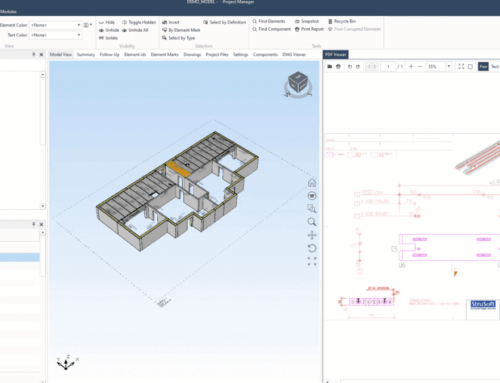

After completing the initial task, HTH required the IMPACT’s Production Module to continue their work efficiently. This module played a vital role in aiding them with various aspects, including production planning, optimizing casts/beds for precast element manufacturing, conducting quality analysis, planning transportation of the precast elements to the designated site, and ensuring proper stacking sequence at the site in alignment with the construction plan. IMPACT’s automated functionality seamlessly handled all these tasks, simplifying the process for HTH.

The Design Phase

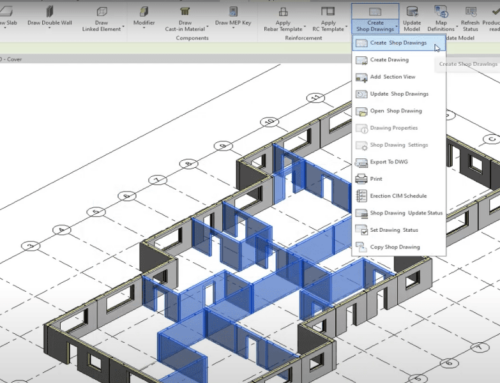

The design phase is crucial in ensuring the accuracy and efficiency of precast projects. With IMPACT, the builder gained access to a sophisticated set of design tools that enabled them to create complex precast elements with precision and ease. The software’s advanced modeling capabilities allowed for the efficient integration of architectural and engineering designs, ensuring optimal structural performance while adhering to aesthetic requirements.

Production Phase

Once the designs were finalized, the production phase kicked into gear. IMPACT facilitated seamless collaboration between the design and production teams. The software’s integrated production planning and optimization tools allowed for efficient material management, automated rebar detailing, and accurate production sequencing. As a result, the builder achieved significant time and cost savings while maintaining the highest quality standards.

Project Management

Managing the intricacies of a precast project can be challenging, given the numerous stakeholders involved. IMPACT provided the builder with powerful project management features, including resource allocation, progress tracking, and real-time communication tools. The software’s ability to generate detailed reports and documentation streamlined communication between teams, reducing delays and ensuring everyone was on the same page throughout the project’s lifecycle.

Benefits and Results

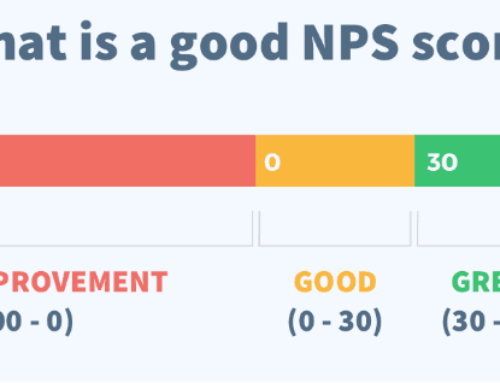

By embracing StruSoft’s IMPACT Precast Software, the precast builder in Ireland experienced remarkable benefits and achieved outstanding results:

- Improved Efficiency: The software’s integrated design, production, and project management capabilities optimized the builder’s workflows, significantly reducing project timelines and increasing overall efficiency.

- Enhanced Collaboration: The software’s centralized platform facilitated seamless collaboration between different teams and stakeholders, ensuring clear communication and coordination throughout the project.

- Cost Savings: The builder witnessed substantial cost savings through reduced material waste, improved resource allocation, and efficient production planning.

- Superior Quality: By leveraging the software’s advanced design and production features, the builder achieved unparalleled precision, consistency, and quality in their precast elements, meeting and exceeding industry standards.

- Competitive Advantage: The successful implementation of IMPACT Precast Software positioned the builder as a leader in the precast construction industry, enhancing their reputation and attracting new clients.

The precast builder in Ireland serves as a testament to the transformative impact of StruSoft’s IMPACT Precast Software. By integrating cutting-edge technology into their precast construction processes, the builder achieved remarkable improvements in efficiency, collaboration, cost savings, and quality. As the demand for precast solutions continues to rise, embracing innovative software solutions like IMPACT will become increasingly crucial for staying competitive and delivering successful precast projects.

Would you like to learn more about IMPACT software and perhaps be interested in receiving a free demo and consultation on how we can support your Precast business? Then don’t hesitate to Book a 1:1 Teams meeting with one of our IMPACT representatives – they will be happy to help you. Or you can follow the form below to Book a Demo.