QR Codes

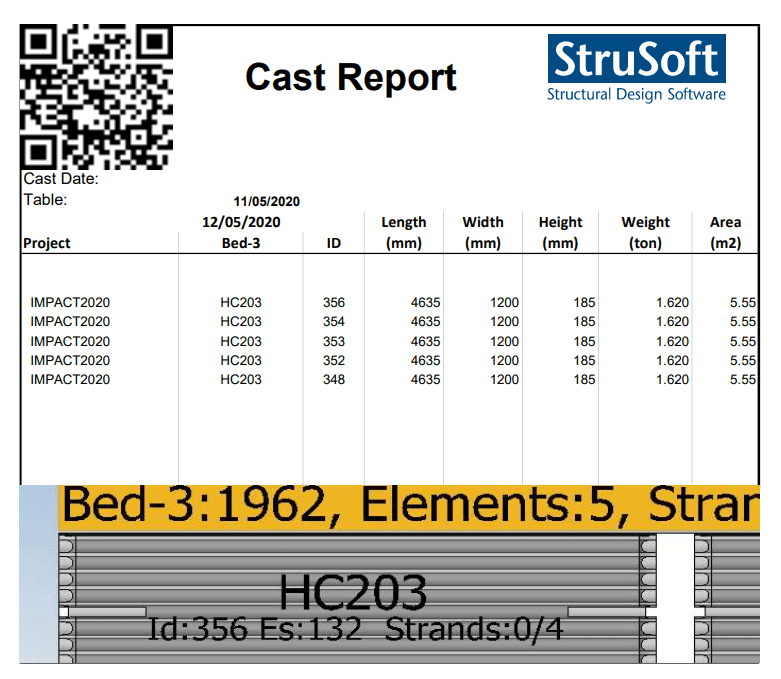

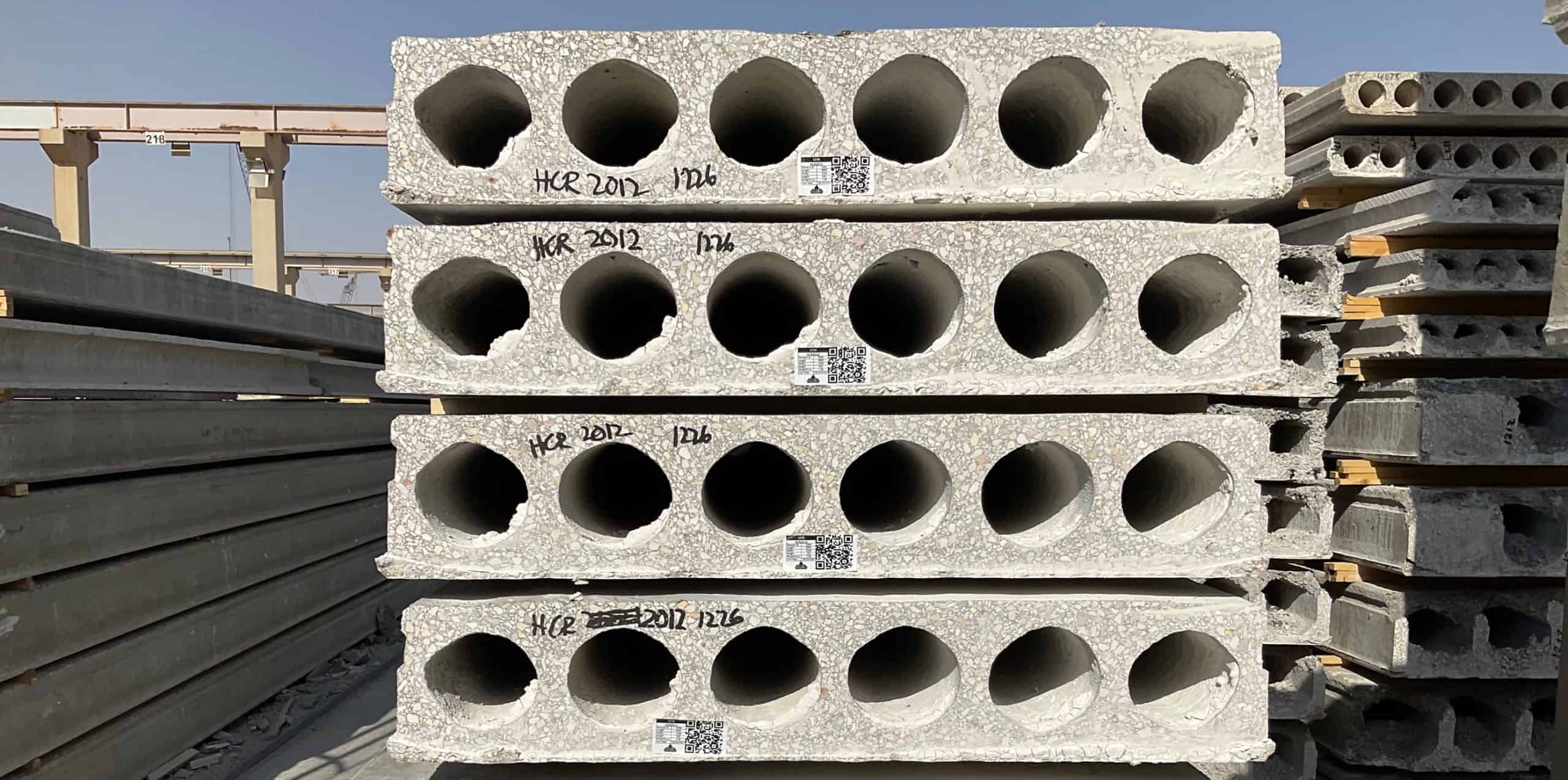

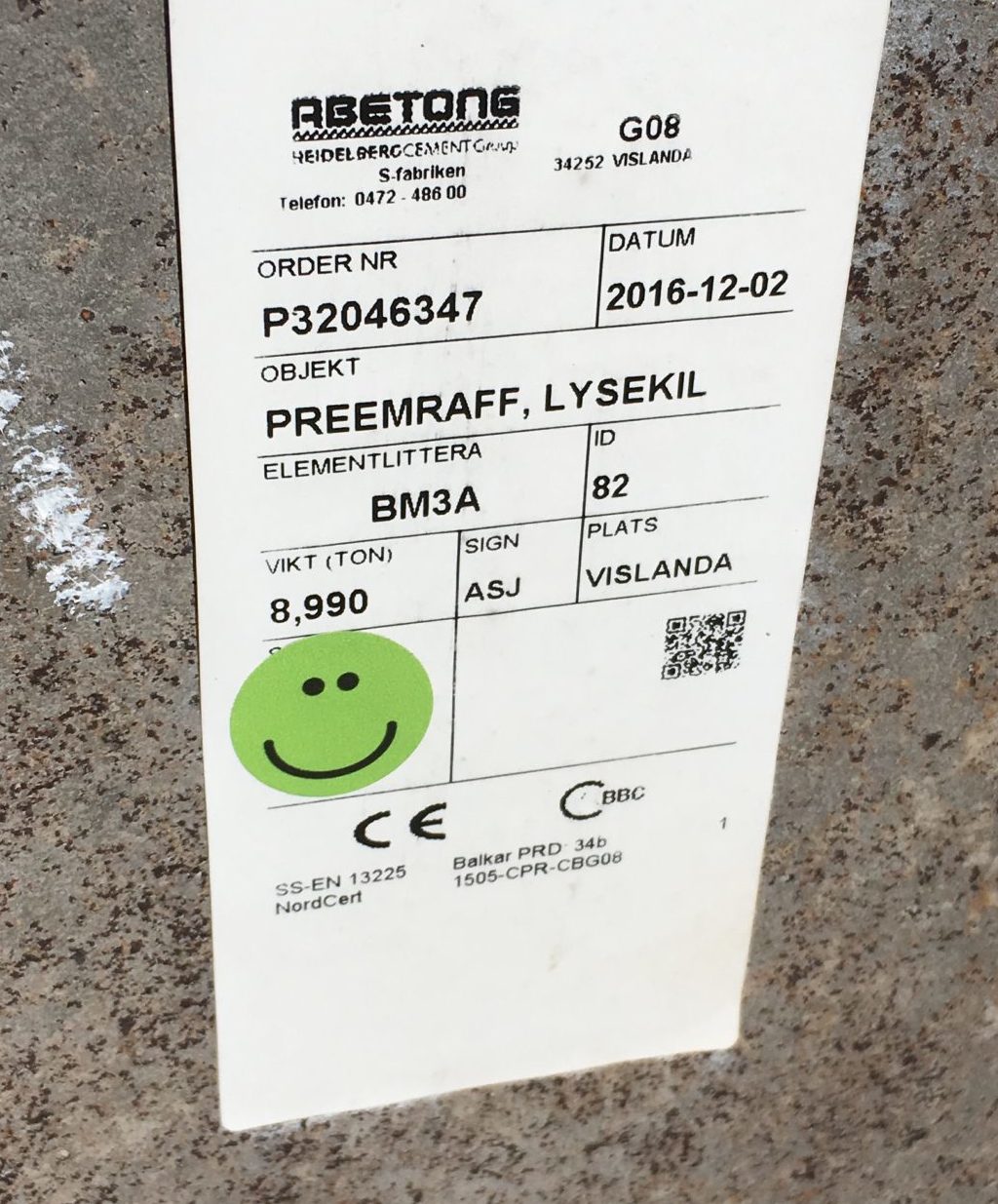

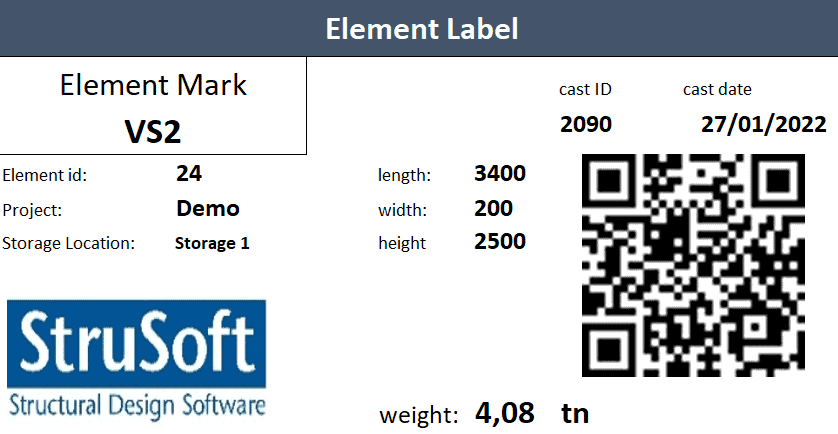

The IMPACT software generates unique QR Codes for every precast element that is designed/imported into the database. Every single precast element stored in the IMPACT database is given a unique ID number.

This will help you comply with any European or International certification methods for traceability requirements but in reality, the real value to you, is that you will be able keep track of every single precast element through any stage of the precast design, production or project processes in real-time.

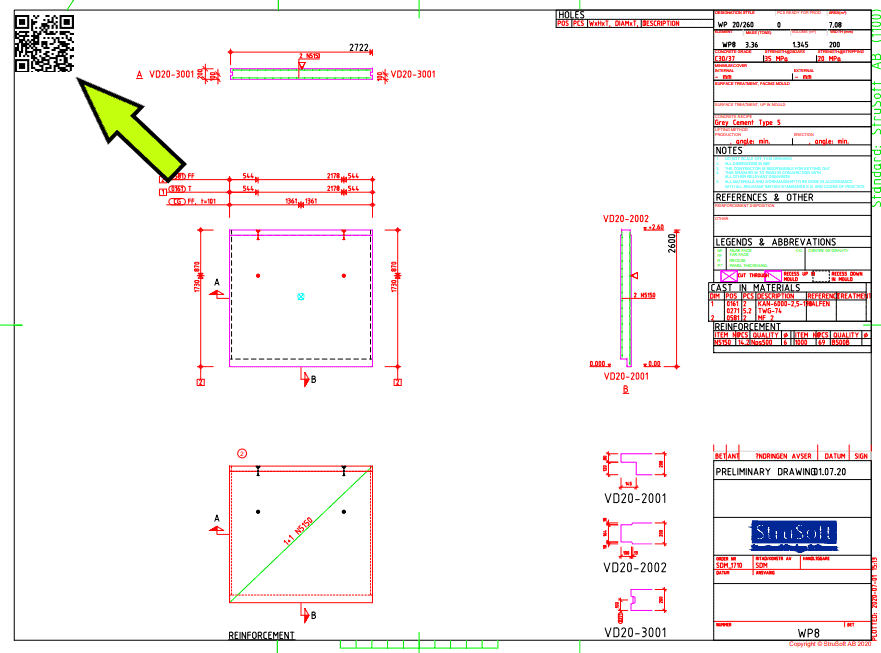

You scan the QR Codes with the IMPACT Go mobile application and can then interact with your real-time data. You can get information such as precast element properties, change status‘, perform element controls and review shop drawings, just a few of the key functions of our mobile app.

QR Codes can be generated on anything in IMPACT

You can put QR Codes on anything in the Report Tool such as Cast reports, Stack Reports, Transport notes. You can even put QR Codes on shop drawings for design approval checks as part of the IMPACT Design module. QR Codes can be generating for anything in IMPACT to help keep better track of any area of your precast process.

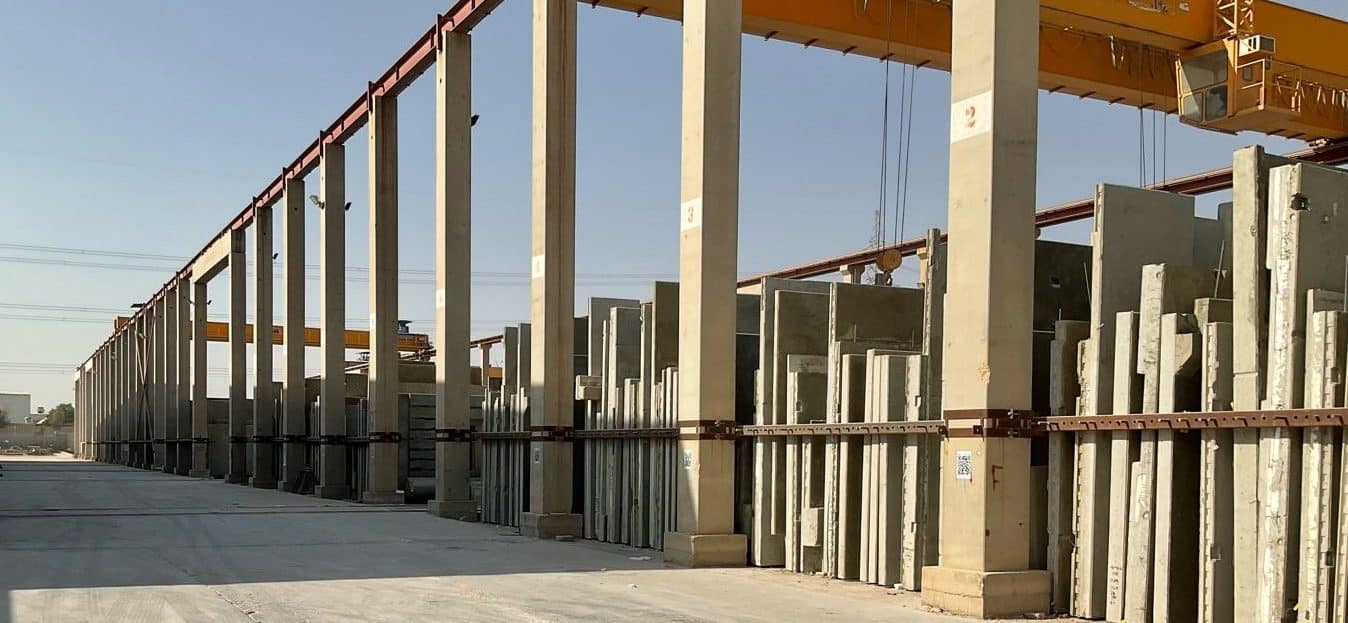

QR Codes on Storage Locations

You can even generate QR codes for Storage Locations in IMPACT and divide your precast stock yard into specific bays. When you combine the QR coded Storage Locations together with the Stack Planning module you are then able to manage your stock yard and precast element movements simply by scanning the QR codes with the IMPACT Go mobile application and updating the storage location with movement in/out of the precast elements. There are a few photos below with examples from our customers to give you an idea.

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Blog

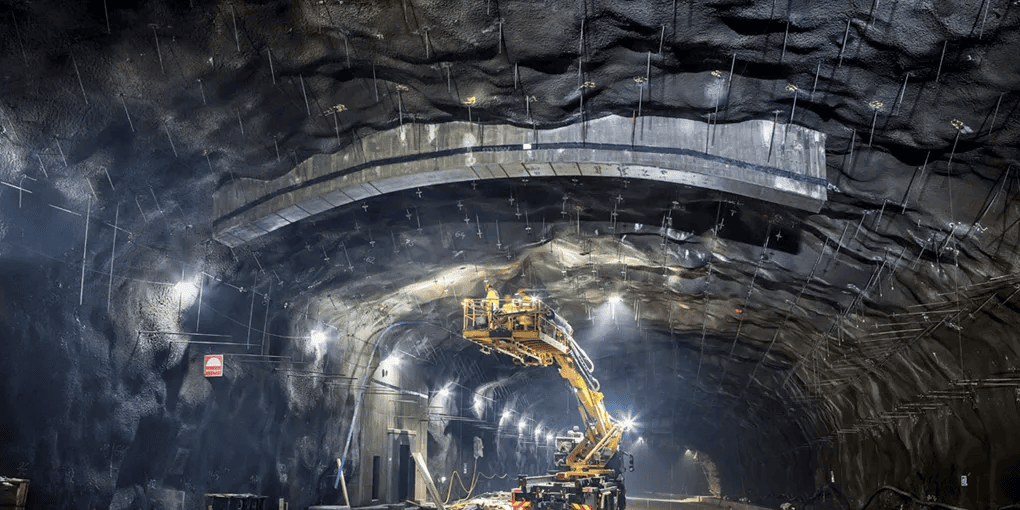

Optimizing Tunnel Element Production: A Case Study on AF Prefab’s Efficiency with IMPACT

Introduction

In the heart of Mälardalen in

IMPACT User Conference 2023 – Nice to see all our customers again

On Thursday, the 9th of November, we hosted our annual IMPACT User Conference – Live from Malmö – with more than 100 participants and […]

IMPACT for Infrastructure Projects – Plinths

In our exploration of the IMPACT infrastructure articles, we’re delving into a fascinating case study concerning plinths – a crucial element that’s been revolutionized through […]