Sandwich Wall Design

Watch the Sandwich Wall Design Overview Video for CAD

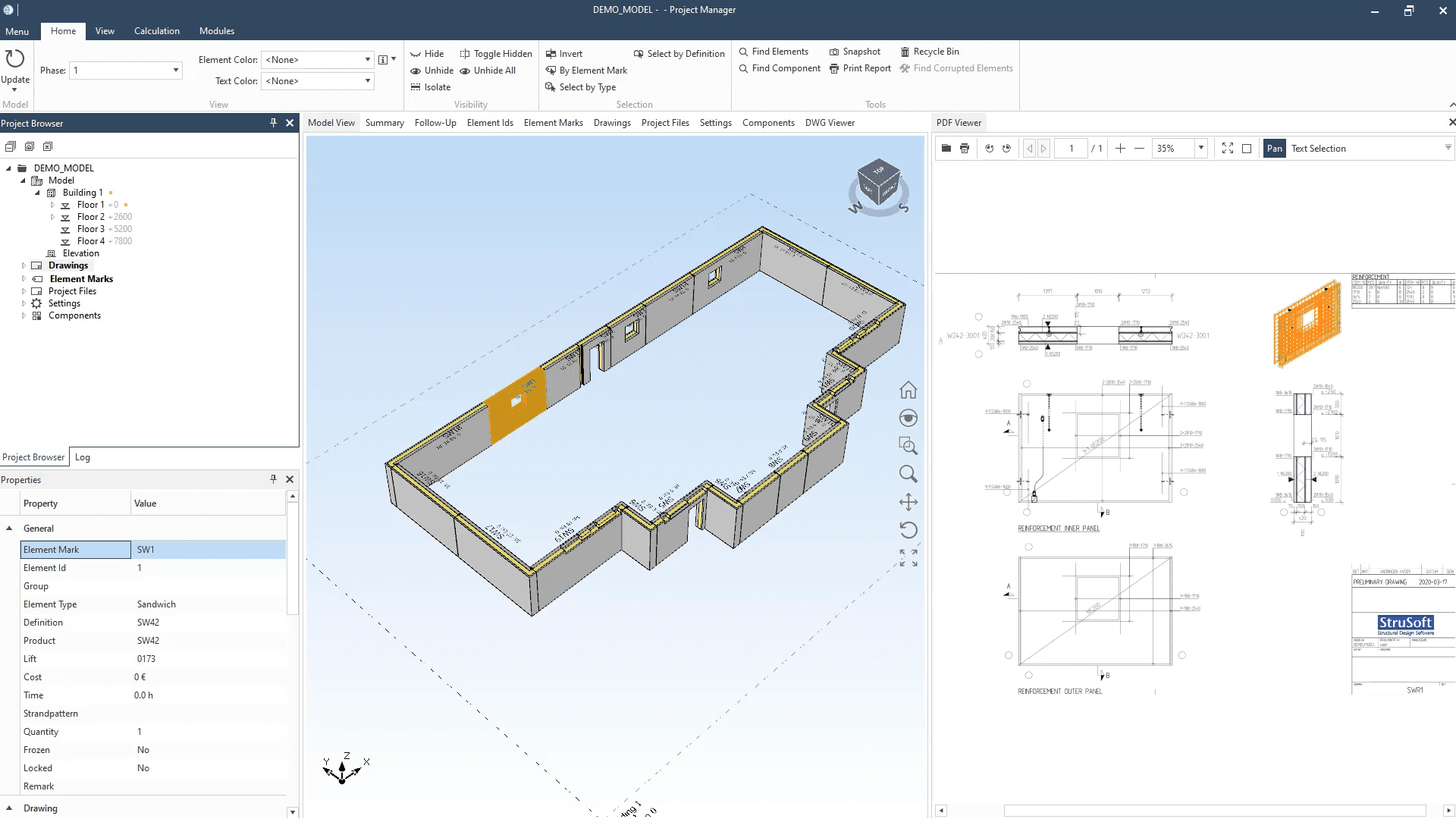

The Sandwich Wall Design module in IMPACT helps you design and detail precast sandwich walls in 3D, including automatic lifting and bracing placing and automatic centre of gravity calculation. Cast in materials and wall edge chamfer details including connections are also automated.

The software also generates automatic 2D shop drawings (including 3D representation) and in conjunction with the IMPACT Reinforcement module speeds up the rebar detailing process with automatic reinforcement templates and bar bending schedule (BBS) reports with shape codes and all bar/mesh weight info.

Any changes you make in the 3D model, plan, elevation, or on the shop drawings, are immediately updated on all corresponding drawings and models. The entire workflow is synchronized across all drawing areas with all corresponding project drawings automatically saved and updated at regular intervals.

Automation features within the IMPACT Sandwich Wall module include but are not limited to: electrical keys (MEP); cast-in materials; automatic connection details; chamfers; door & window openings; recesses; edge details; lintels; wall ties; thickenings, insulation and advanced geometries.

IMPACT Sandwich Wall can be provided as a standalone module or as part of the entire IMPACT Design Suite. We have developed custom automation on AutoCAD, BricsCAD, and Revit and there is flexibility to use the same software license through any of these three Industry-standard CAD and 3D modelling software.

Watch the Sandwich Wall Design Overview Video for Revit

Our Team of experts can guide and support you to help you find the best solution. Please feel free to get in touch if you would like to find out more.

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Wiki

Full details Sandwich Wall module can be found on the IMPACT Wiki by clicking here.

IMPACT Blog

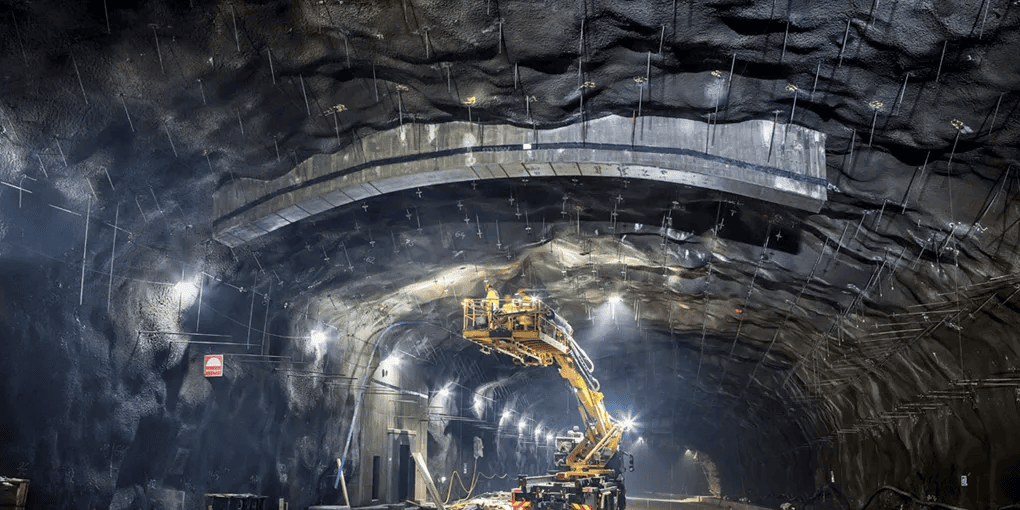

Optimizing Tunnel Element Production: A Case Study on AF Prefab’s Efficiency with IMPACT

Introduction

In the heart of Mälardalen in

IMPACT User Conference 2023 – Nice to see all our customers again

On Thursday, the 9th of November, we hosted our annual IMPACT User Conference – Live from Malmö – with more than 100 participants and […]

IMPACT for Infrastructure Projects – Plinths

In our exploration of the IMPACT infrastructure articles, we’re delving into a fascinating case study concerning plinths – a crucial element that’s been revolutionized through […]