Precast Shop Drawings

IMPACT Design provides unlimited options and full automation to help you produce fast and accurate Precast Shop Drawings.

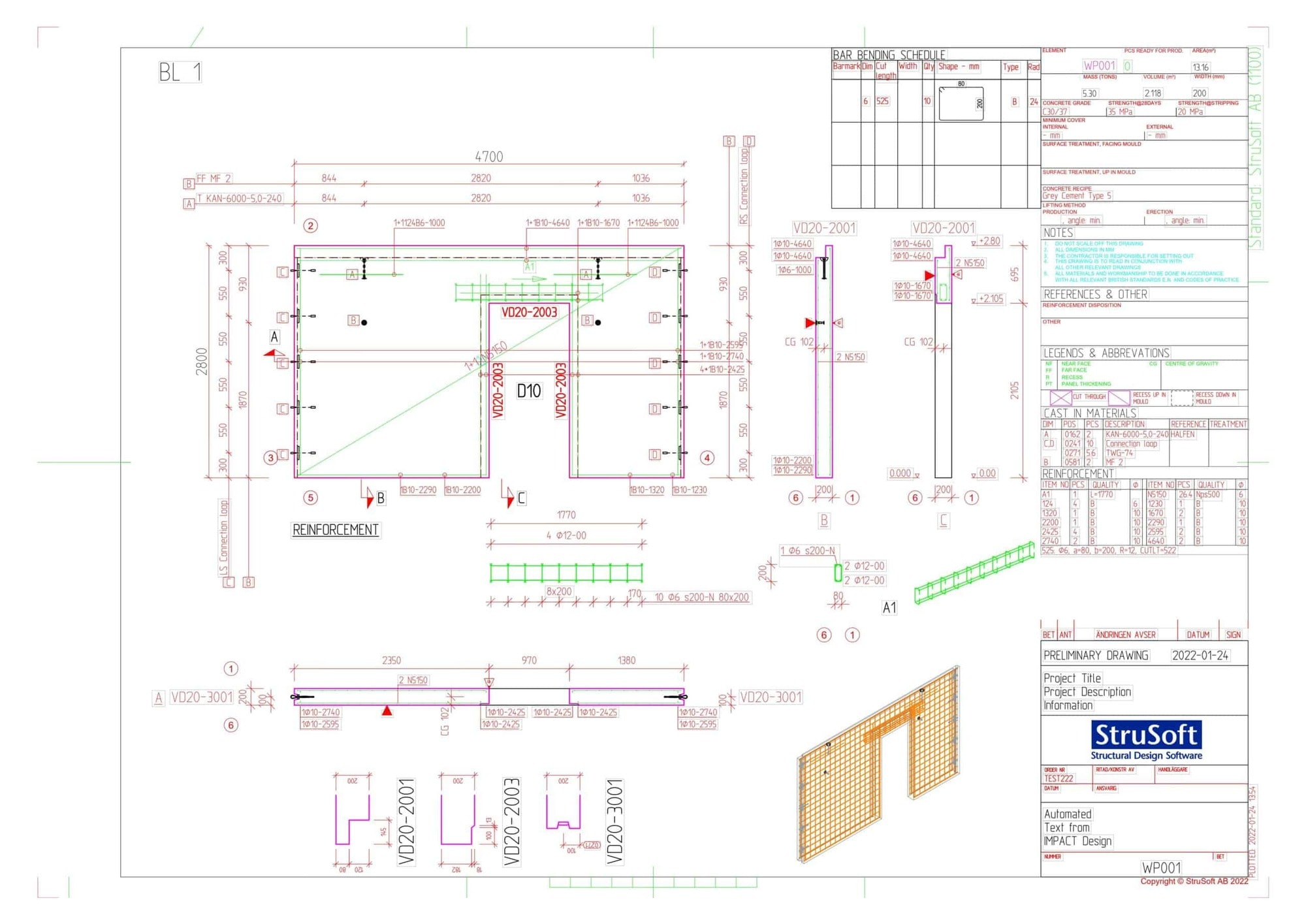

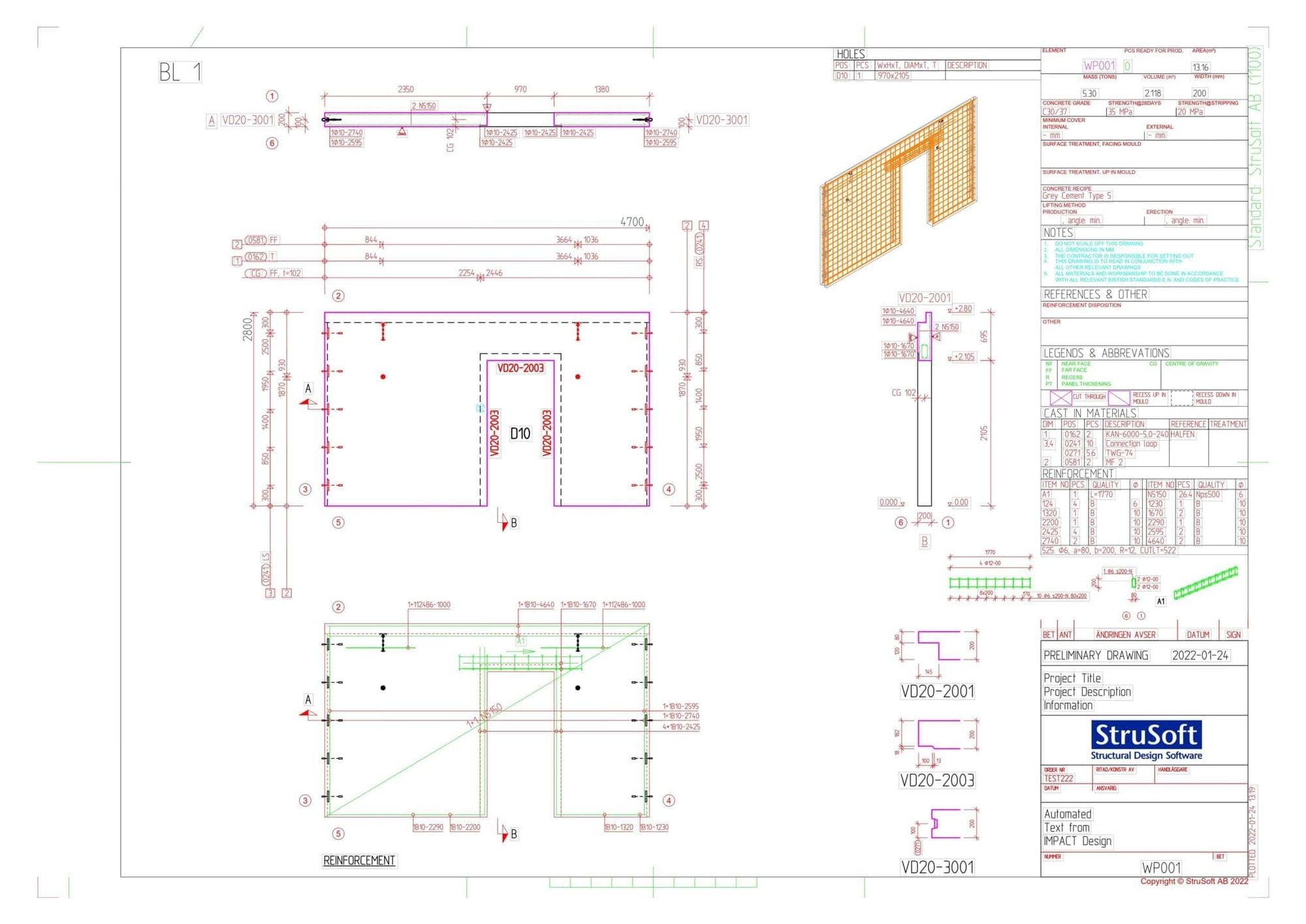

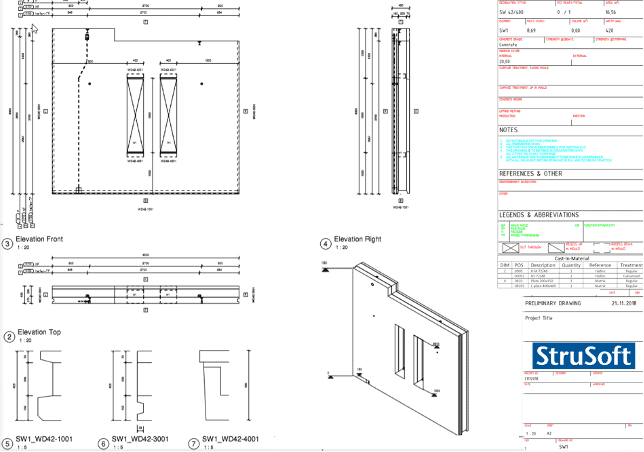

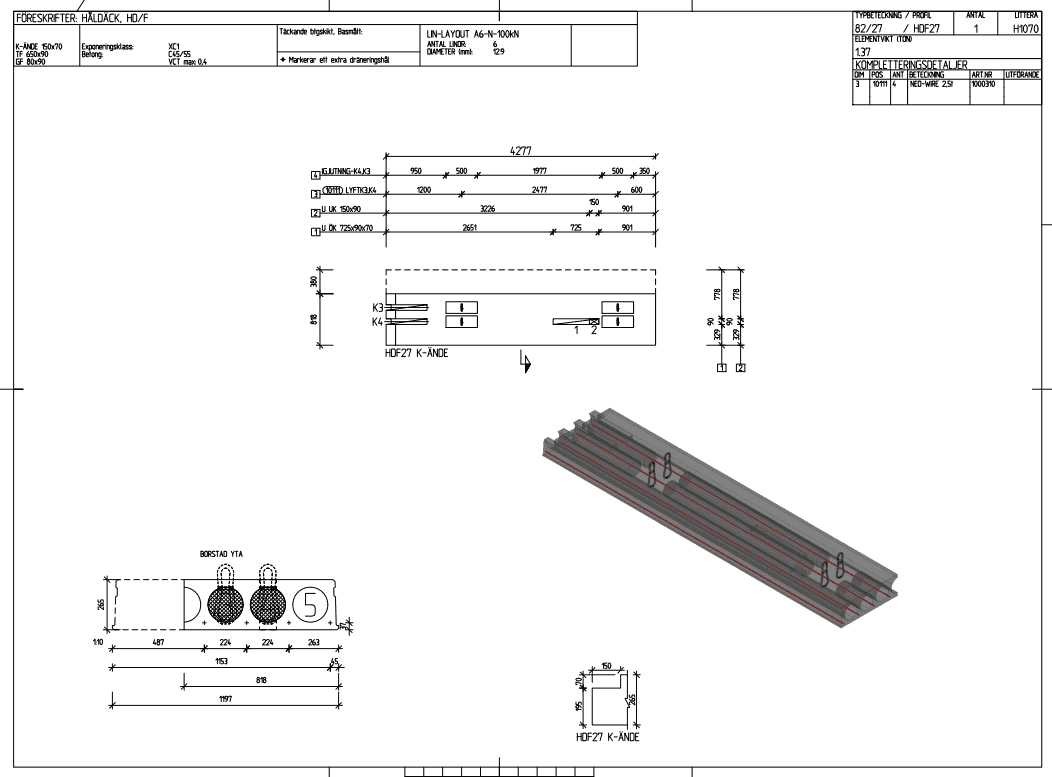

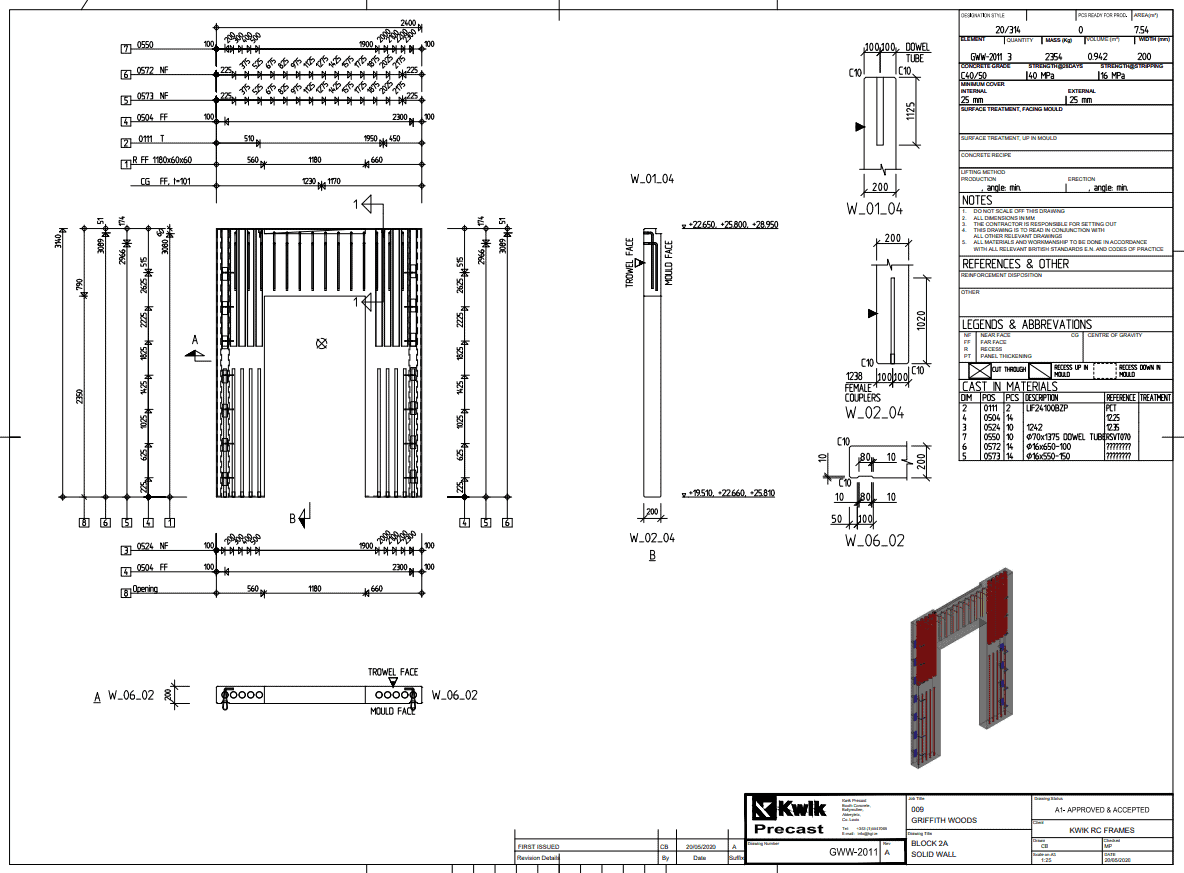

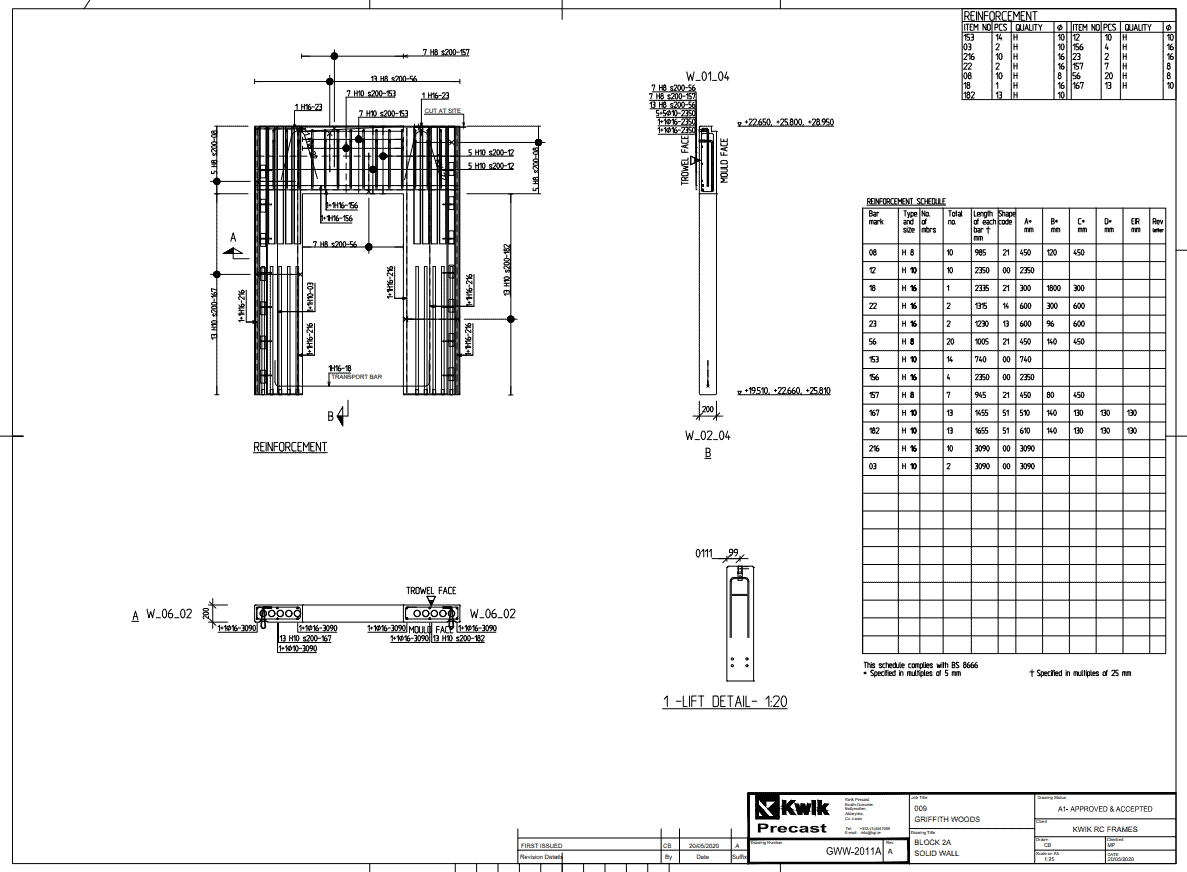

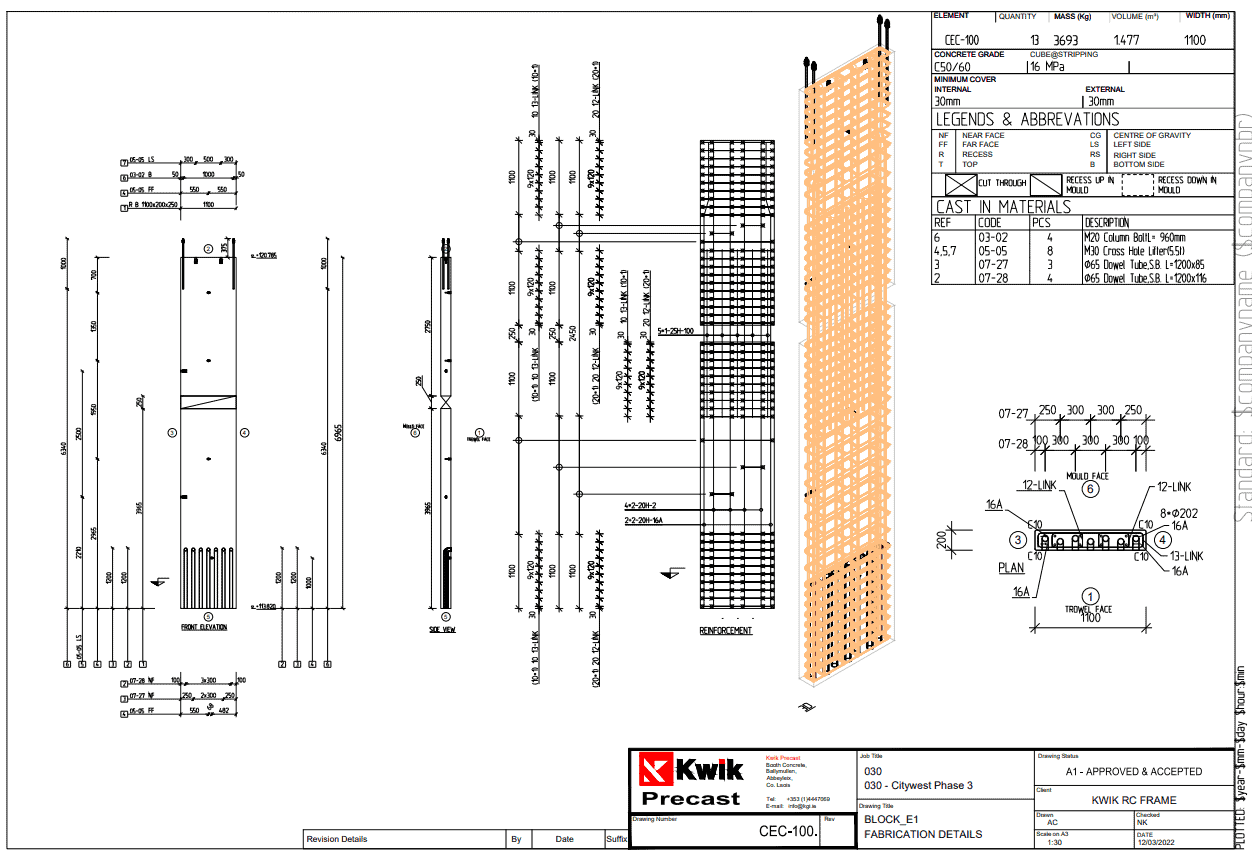

Once the 3D/2D modelling of the precast elements has been completed, you save all element data to the IMPACT database. From the information in the database, you can then create automatic shop drawings of your precast elements. Below are some example layouts for different types of precast elements and all are fully automated.

Completely Customisable and Automated Precast Shop Drawings

IMPACT Design has an intuitive way of allowing you to customise the layout and look of the precast shop drawings. Every Country and every individual Precast Factory have different approaches and requirements for the layouts of precast shop drawings. There is not a right or wrong approach and IMPACT Design has been developed to cope with many different drawing standards and customisation requirements.

As well as the Shop Drawings for all Precast Element Types, you can also create automatic reinforcement/rebar bar bending schedules (BBS) with individual and total bar weights.

As part of the set-up and implementation of IMPACT Design, StruSoft provides you with full support to create company standards which includes the precast shop drawing templates, customised for your exact company requirements.

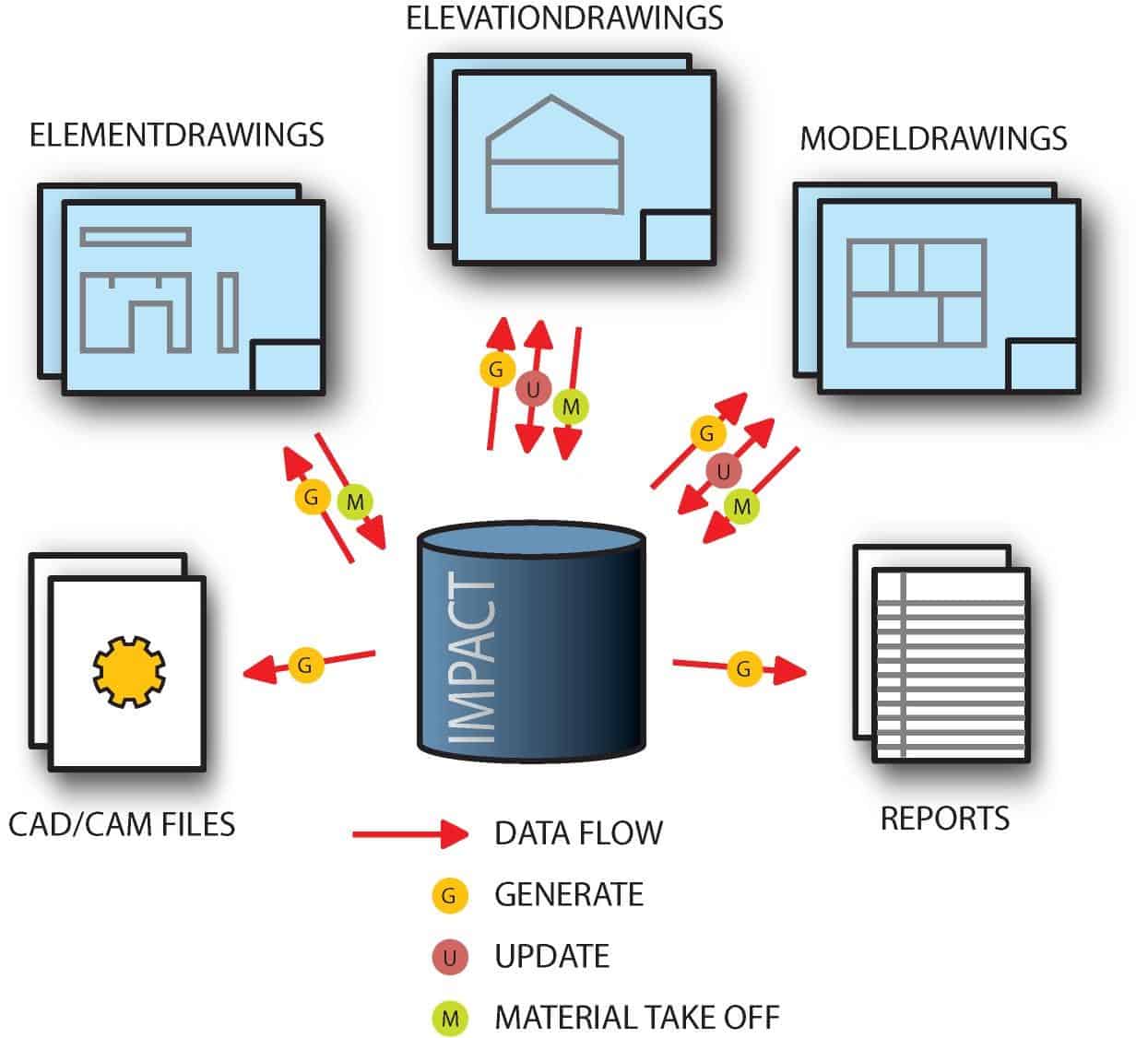

All design areas are synchronised and any changes you make in one area update across all areas.

Since all IMPACT Design applications share the same information in the database, it is also possible to make changes to the shop drawing and update your model (floor plan) or elevation drawings with automatic changes and vice versa. This ensures you maintain accuracy and quality but enables you to detail with speed during the precast design process.

Watch a Webinar about Precast Shop Drawings

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Wiki

Full technical details on Precast Shop Drawings can be found on the IMPACT Wiki by clicking here.

IMPACT Blog

Precast Detailing in IMPACT for Revit – A Webinar series of 3 (Watch it now)

Discover IMPACT for Revit by tuning in to our webinar series on Precast Detailing

Throughout the first quarter of 2024, we hosted a series of […]

Precast Apartments Case Study: Pekabex & Kritter

In the heart of Stockholm, new precast apartments are taking shape at Slagsta Strand Kv7. This project is a testament to innovation and expertise, with […]

IMPACT for Infrastructure Projects – Plinths

In our exploration of the IMPACT infrastructure articles, we’re delving into a fascinating case study concerning plinths – a crucial element that’s been revolutionized through […]