IMPACT BricsCAD

IMPACT BricsCAD was released in 2018 and full integrates both IMPACT Precast Design and IMPACT Reinforcement. This provides a fantastic option for Precast Designers looking for a competitive CAD solution.

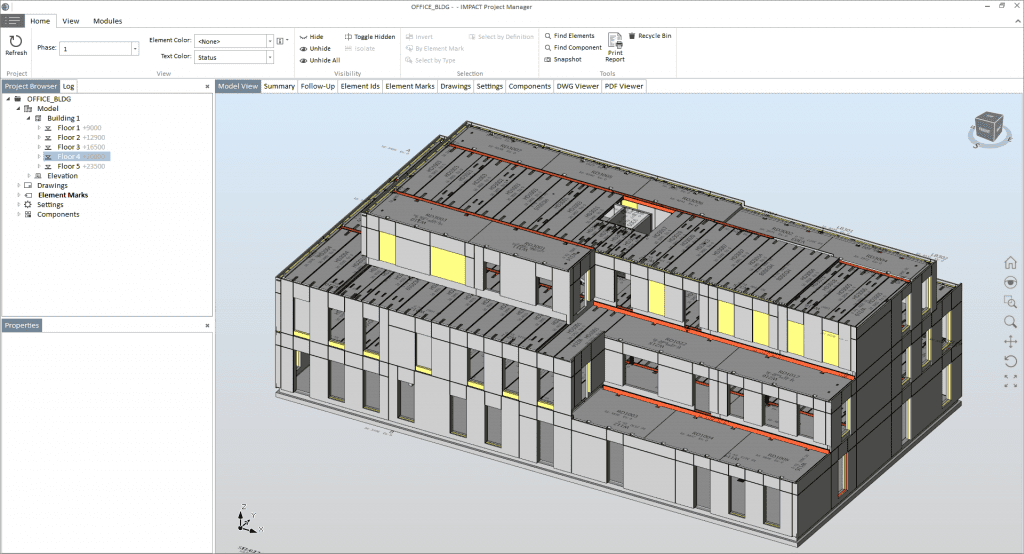

Create a 3D BIM Workflow without limitations with IMPACT BricsCAD

BricsCAD offers highly competitive pricing on licenses, and a range of desirable features for the creation of a full BIM workflow. This is all achieved using industry-standard DWG and rapid IFC export.

SQL Database behind IMPACT BricsCAD

The heart of IMPACT is an SQL database, which integrates behind IMPACT BricsCAD to link all the elements of a precast construction project. Real-time access for stakeholders at all levels enables greater control over overtime schedules, materials, and accuracy. This reduces costs, increases productivity, prevents errors and conflicts.

With a customised IMPACT database, customers using IMPACT BricsCAD can design precast elements in 2D and 3D, with automated production drawings – including dimensions and reinforcement.

In fact, IMPACT information is available on every single element designed in IMPACT BricsCAD, such as lifters, statuses, and planning dates.

Available elements include columns, beams, walls, floor slabs, and more. These can also be linked with Revit and Tekla models. Production planning maximises efficiency throughout manufacture, from raw materials and casting, to loading and erection.

To see how IMPACT BricsCAD can improve your workflow please look at our IMPACT Wiki page by clicking here.

Model and Schedule Rebar for Reinforced Concrete (RC) with IMPACT BricsCAD

IMPACT Reinforcement is an application to model and schedule rebar for both precast and in-situ concrete in IMPACT BricsCAD.

With smart objects containing all the necessary information to define rebar – including bar mark, shape code, leg lengths, end hooks, and material – you can draft quickly and create schedules at the click of a button.

Quantities are calculated automatically, and bars are shown as easily read symbols or 3D solids. If you are working on large projects, multiple DWG files are easily connected for common scheduling, with filtering based on bar data for easier call-off.

As with all our software, IMPACT RC can be adapted to meet your individual user or company standards to achieve a consistent, unified style throughout your projects. Your rebar data can also be exported to XML and BVBS or saved directly to Celsa Steel services QR web schedule service.

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Blog

Precast Detailing in IMPACT – A Webinar series of 3 (Watch it now)

Discover Precast Detailing in IMPACT by watching our webinar series.

We are happy to share the entire webinar series, Precast Detailing in IMPACT, as a […]

Precast Detailing in IMPACT for Revit – A Webinar series of 3 (Watch it now)

Discover IMPACT for Revit by tuning in to our webinar series on Precast Detailing

Throughout the first quarter of 2024, we hosted a series of […]

Precast Apartments Case Study: Pekabex & Kritter

In the heart of Stockholm, new precast apartments are taking shape at Slagsta Strand Kv7. This project is a testament to innovation and expertise, with […]