Precast Detailing Software | IMPACT

Watch the Overview video of IMPACT Precast Detailing Software

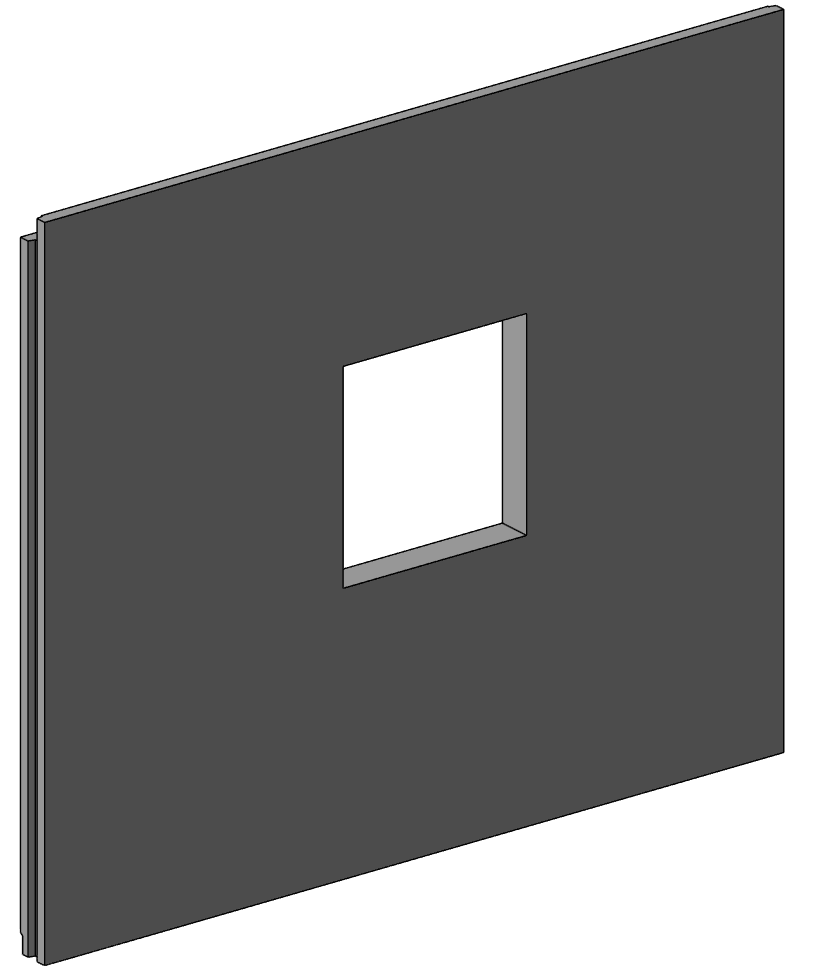

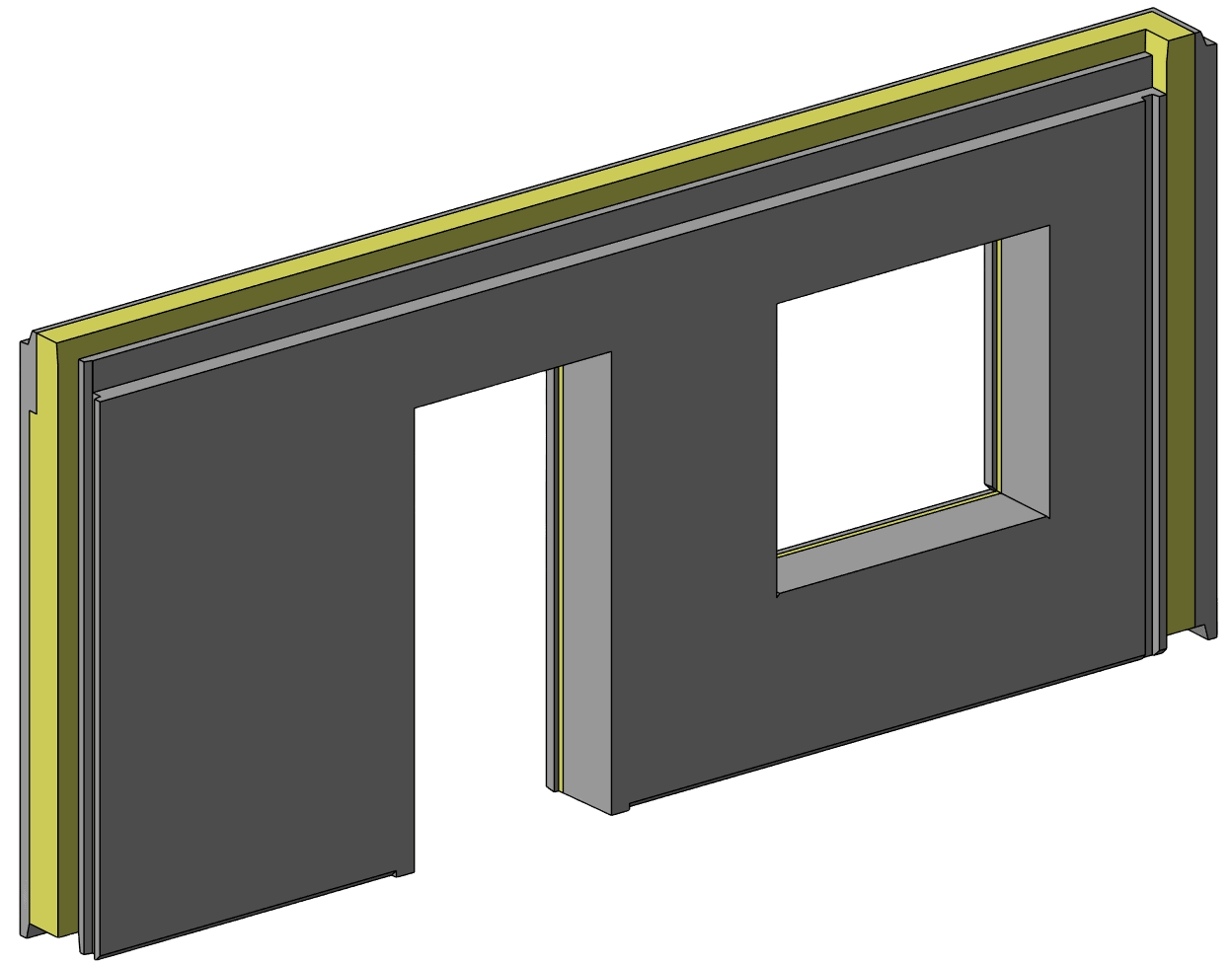

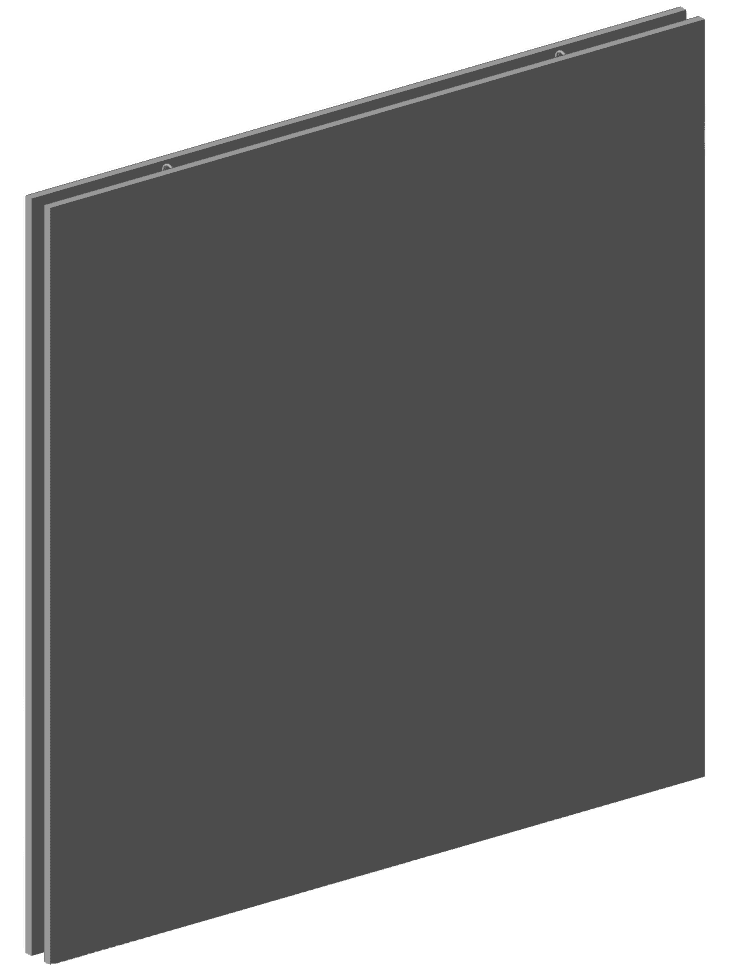

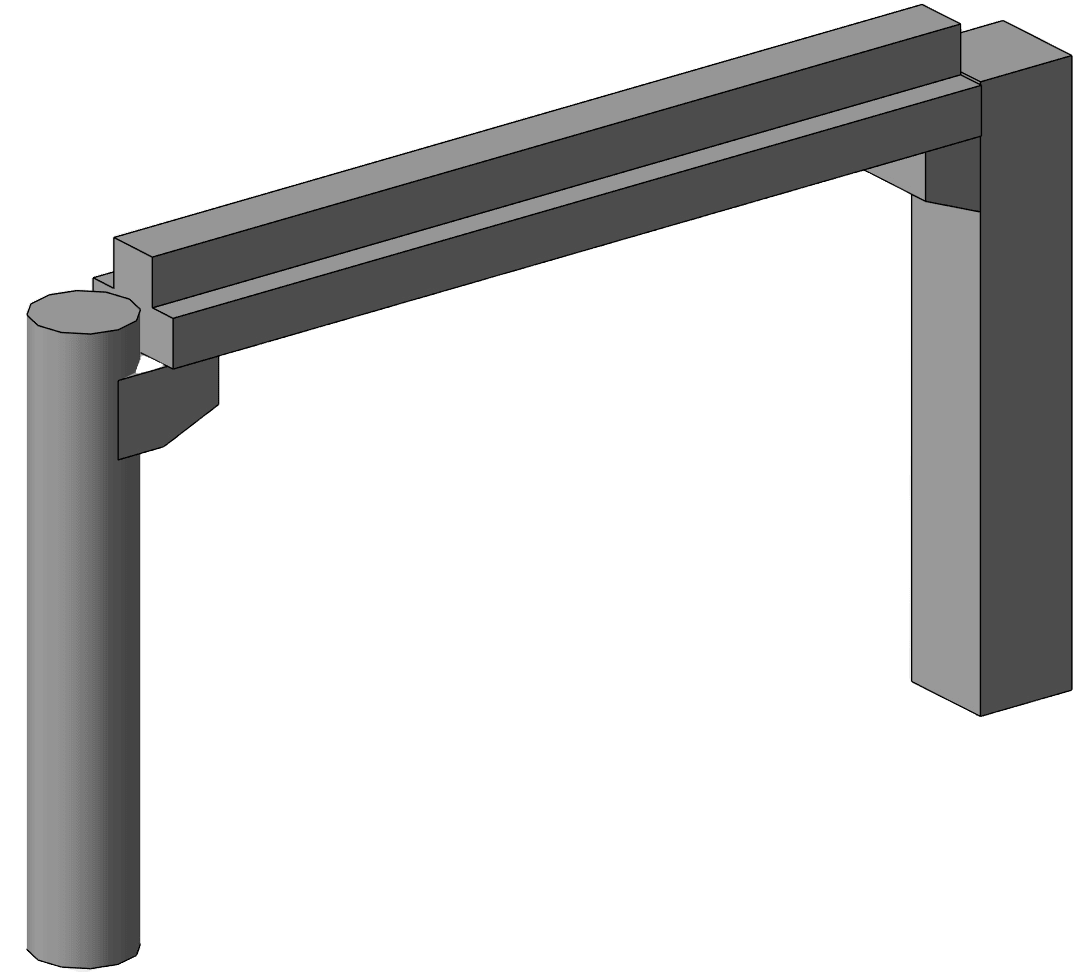

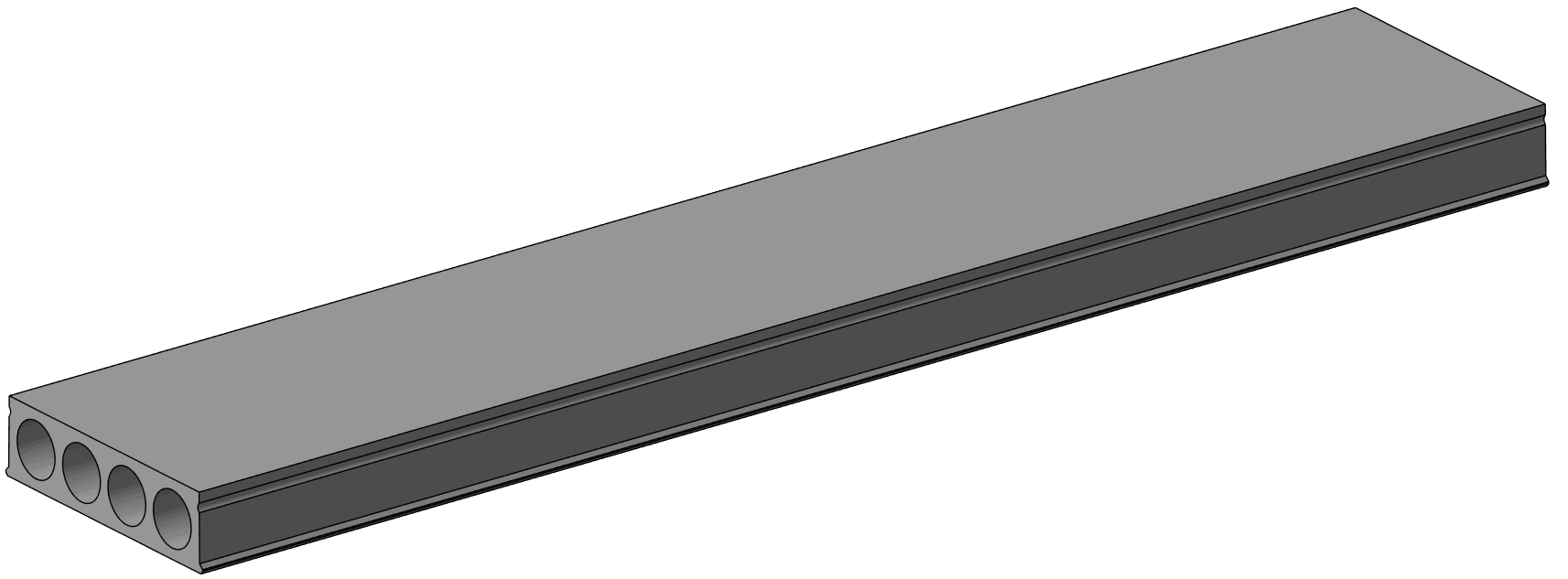

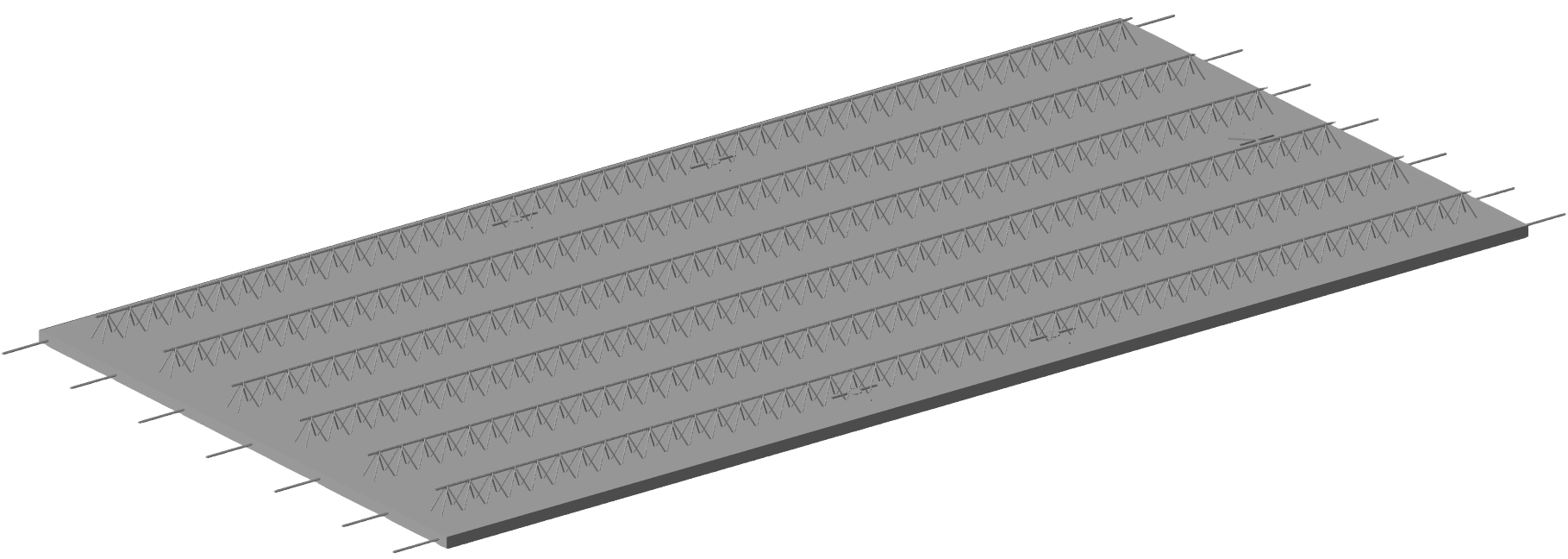

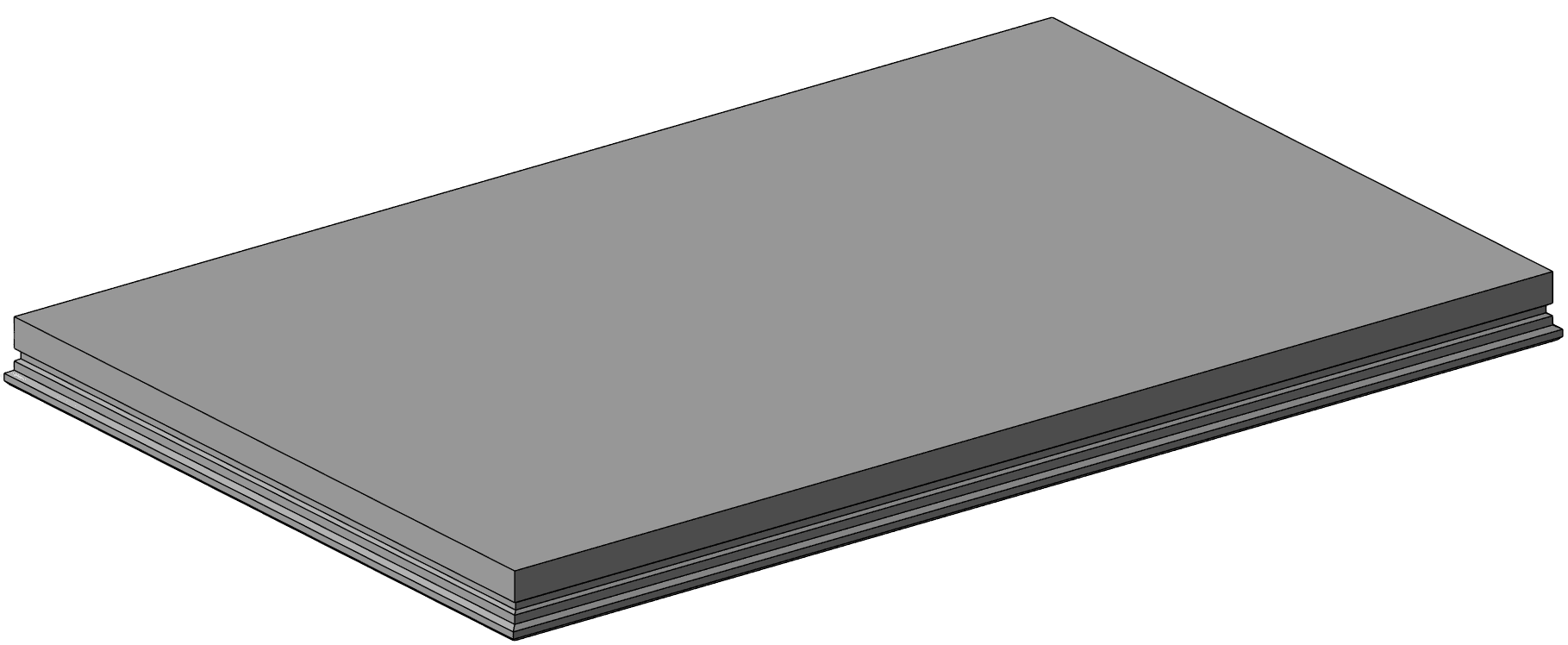

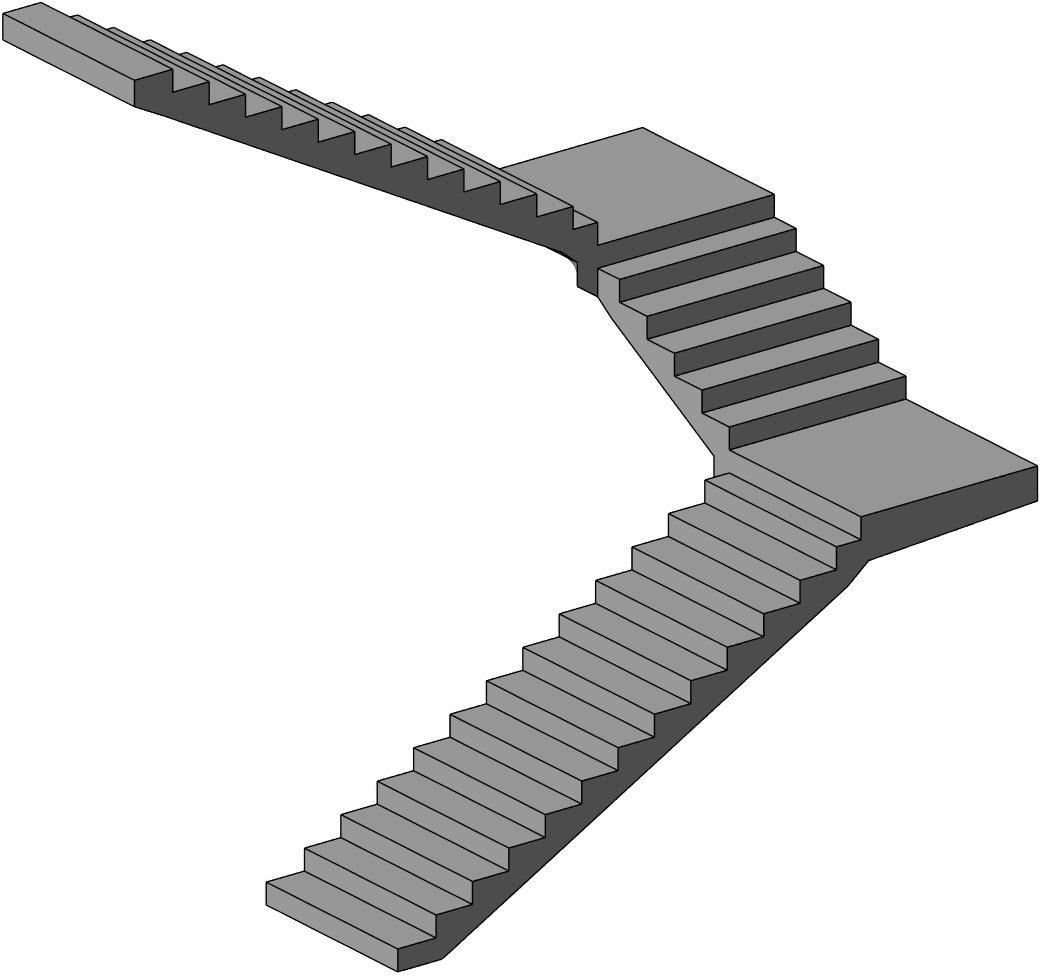

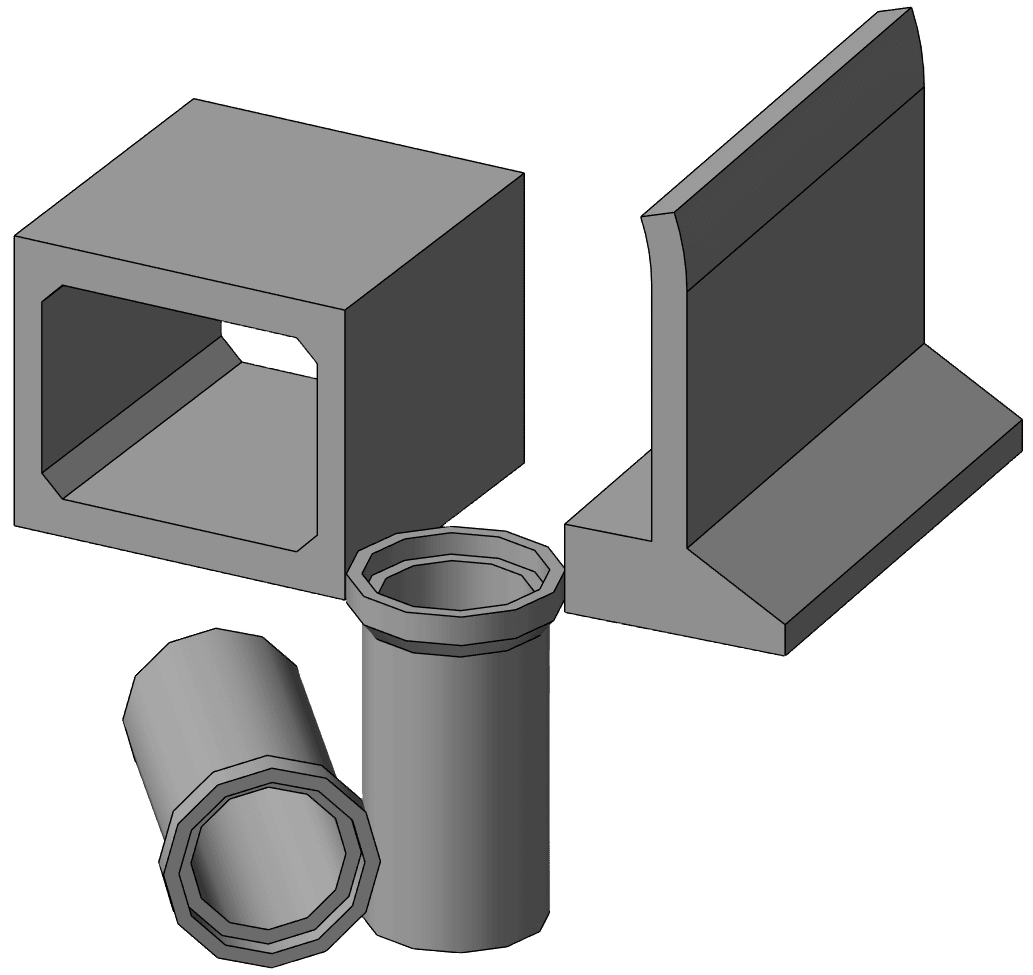

3D model in detail with the IMPACT element design modules

As a designer, you are one of the most important players in a construction project. Through your work, you must ensure that the structures you design fit to their purpose, and are safe, economical, and durable at the same time. To work in detail on every aspect of the element design, we created an entire collection of concrete element design modules through our precast detailing software, IMPACT, to help you work with more speed, precision and automation.

What types of elements can you handle in IMPACT Design?

Why choose IMPACT Design as your Precast Detailing Software?

All the tools that you need in your precast concrete business

IMPACT Design provides the tools you need to implement a BIM workflow in your detailing department. It lets you manage every aspect of your precast concrete detailing, 3D modelling and even provides tools for rough planning and erection planning through the integrated Project Manager.

Reduce manual layout errors

Stay away from work overruns caused by rework or design errors with automatic shop drawings. Create a direct impact on your project cost and schedule error reduction by enforcing proper checking and workflow procedures through the IMPACT precast detailing software.

Standardize your design workflows

Let everyone involved know what to do and when to do it. Eliminate inefficient points throughout the design process and reduce the risks involved in the decision-making process.

Avoid design conflicts and outdated files

The entire precast concrete industry is challenged by projects that have increased complexity levels, with more stakeholders involved, higher demands, and shortened lead times. In IMPACT, any changes you make in the 3D model, plan, elevation, or on the shop drawing, are immediately updated and saved to the database, where they are instantly available to other members of the project. Your whole project is synchronised with all drawings up to date at all times.

Minimize design errors

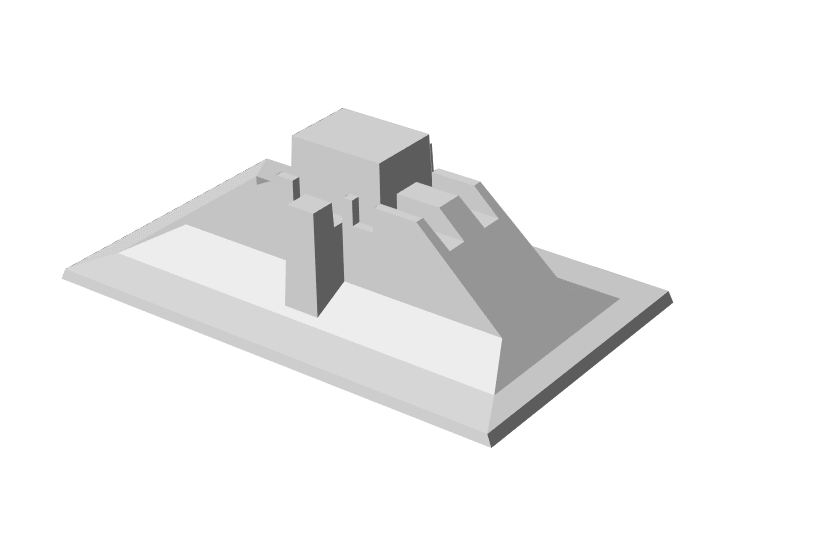

With the 3D modelling capacity, every user can create precise virtual sites and structures. You can easily check, test, and revise your project before moving it to production. Continuously checking the model according to crane, mass, size, and production capacities contribute to the overall efficiency of the project operations.

Speed up your work

Increase the speed of your design and detailing activities by utilising automatic dimensioning functions and reduce project coordination efforts through automatic size checks.

Fully integrate

IMPACT Design is compatible with the main industry software. Get more time to concentrate on the details that matter and leave transfer activities in IMPACT Design’s “hands”. IMPACT Design has a fast learning curve and delivers immediate results since it works within AutoCAD, BricsCAD, and Revit while enhancing their functionality for precast concrete elements.

Automate your processes

Save even more time by taking benefit from IMPACT’s automatic rebar detailing. Use rebar templates always at your disposal, to help you skip time-consuming steps of the process and still reach your objective. IMPACT Design offers high-quality floor plans, shop drawings, assembly drawings, and reports that are easily and automatically generated by each user. The library component utilizes a large number of specialized tools for maximising model accuracy and is expandable in order to model any type of precast element in 3D.

Get unlimited customisation possibilities

IMPACT Design has unlimited customisation possibilities through company standards and can be tailored to fit exactly your precast business. Whether you work as a consultant or run a precast factory, the technicians at StruSoft will make sure you get the correct guidance and company setup.

Fully connected with IMPACT Planning software

The IMPACT system provides not only design tools, but also planning tools for all types of precast elements: Stack and transport planning, Cast planning, Cost planning, Mobile Apps, and more.

Why wait? Get in touch and get started on your journey today!

IMPACT Wiki

Full details about IMPACT Design can be found on the IMPACT Wiki by clicking here.

IMPACT Blog

IMPACT for Infrastructure Projects – Plinths

In our exploration of the IMPACT infrastructure articles, we’re delving into a fascinating case study concerning plinths – a crucial element that’s been revolutionized through […]

Maximizing Efficiency and Precision: Thomas Praefab Utilizes IMPACT Precast Software

In the competitive realm of precast concrete manufacturing, efficiency and precision are paramount. For Thomas Praefab, a leading company in the precast industry, achieving these […]

IMPACT implemented for Industrial Precast Projects with Grupo PACADAR

For the last six months, our colleague Thomas Gitsas has had the pleasure of cooperating with GRUPO PACADAR and