Precast Transport Planning

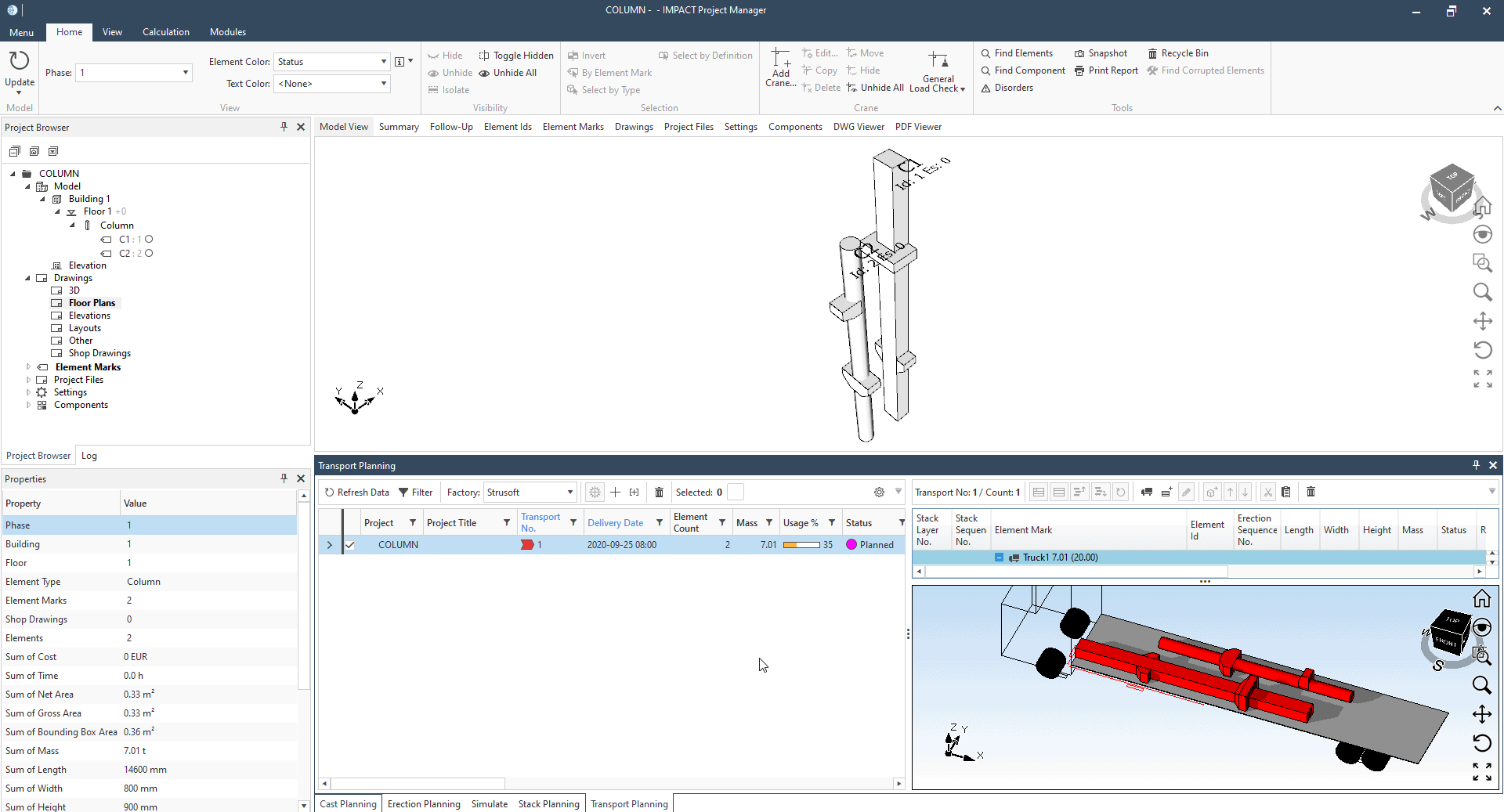

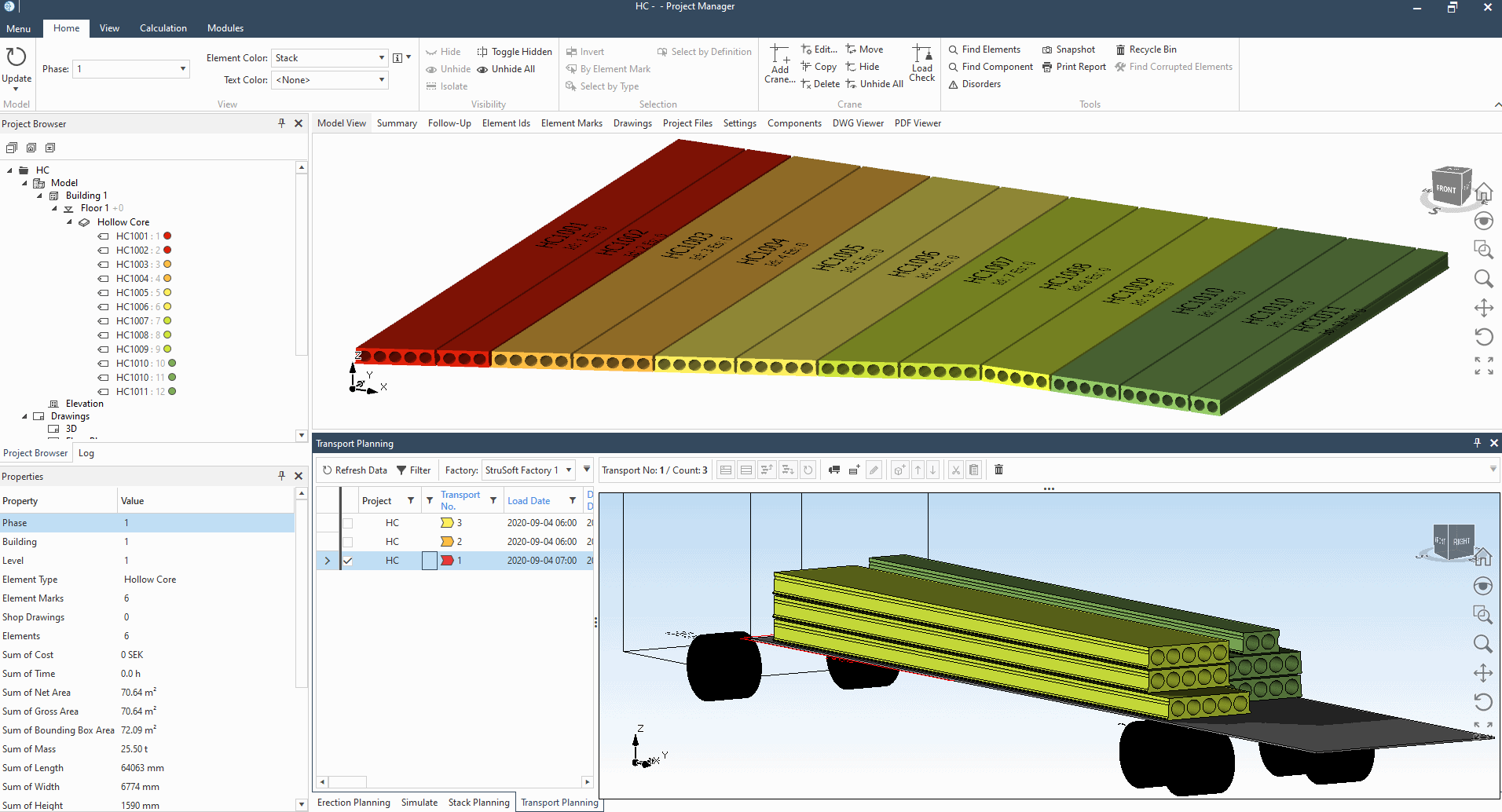

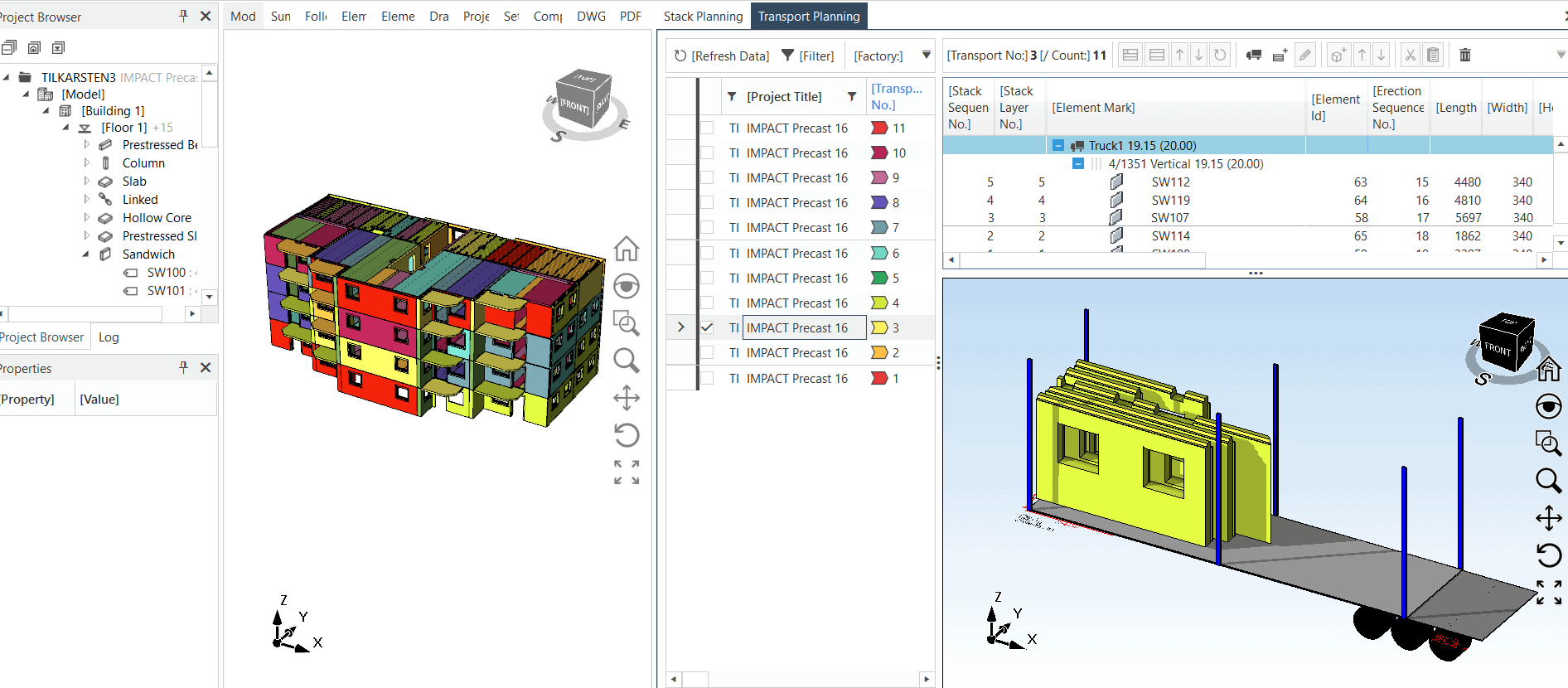

The IMPACT software has a precast transport planning module to help you plan your precast concrete deliveries in full 3D. You can set-up any type of trailer such as Flat Beds, A-Frames and In-Loaders. You can even match and mix your precast element types on trailers, from multiple factory and send to multiple project locations.

The Transport module can help you utilise the most from your deliveries no matter what types of precast elements you need to deliver. You plan in full 3D with the IMPACT Project Manager, which is very simple to use and you don’t require any 3D modelling skills or prior knowledge of modelling software.

Precast Transport Planning for any type of Element

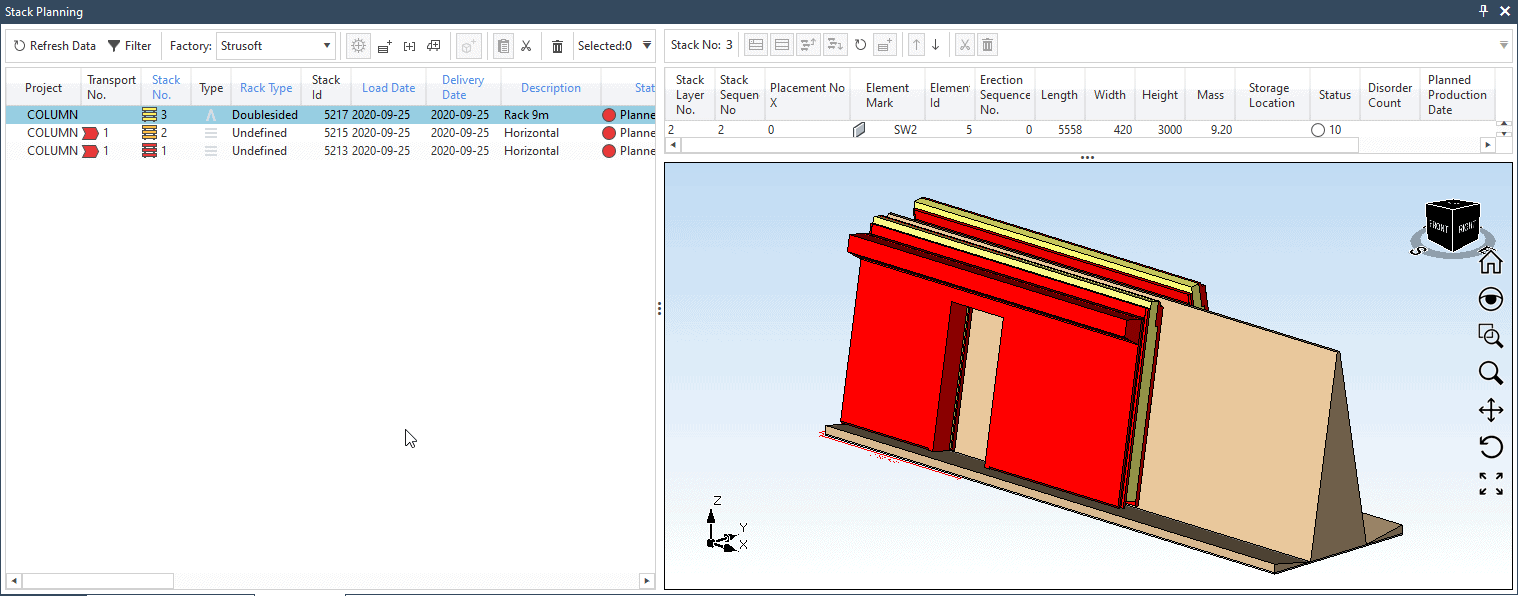

You can design the precast elements in full 3D with IMPACT Design to plan for transportation. You can plan transportation for solid walls, sandwich walls, double (twin) walls and vertically load them on A-Frame type trailers. Filigree (form/half slabs) and hollowcore slabs etc. can be planned horizontally on flatbed trailers. In fact, any type of precast element geometry can be planned for transportation with IMPACT.

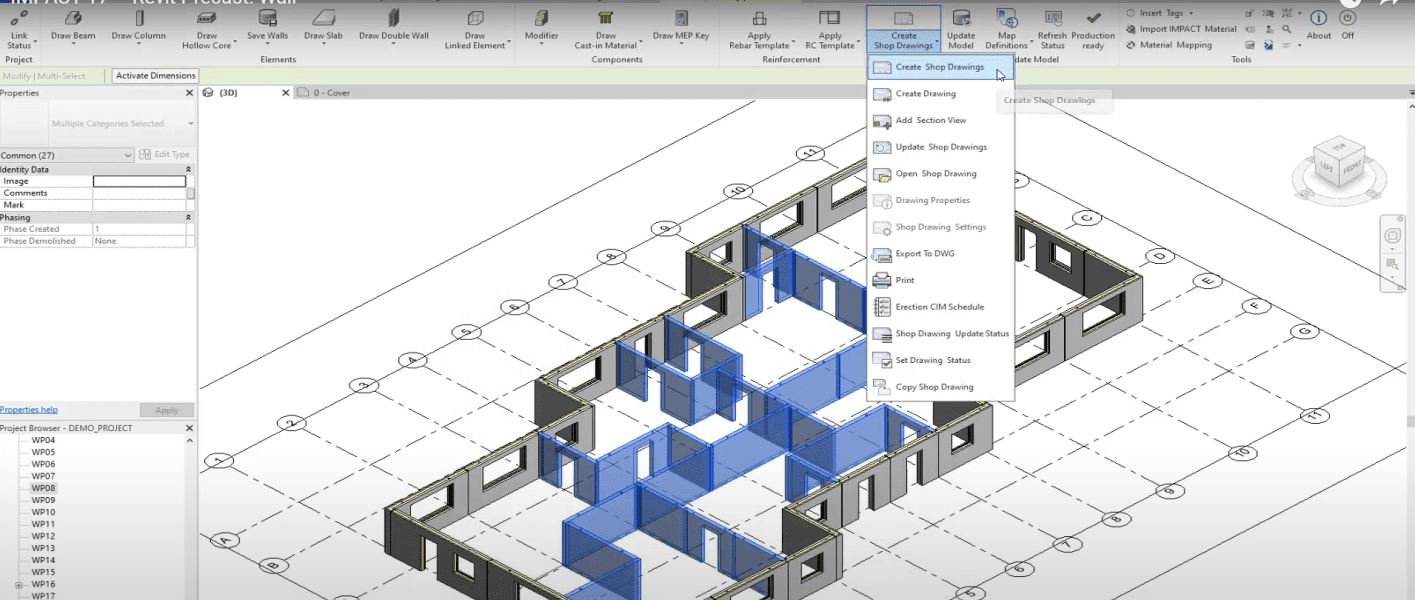

You can also import 3D models and data from other industry-standard software, such as Excel; Revit and Tekla® Structures and plan your transportation using external 3D model data with IMPACT.

Watch the Precast Transport Planning Software Video

Precast Transport Planning Module Features

| Transport Planner Features | Benefits for your Precast Projects |

|---|---|

| Automatic Transport Planning | Plan from Erection Sequence IDs and Stacks |

| Centre of Gravity & Axle Pressures | Vehicles are not overloaded |

| Automatic Utilisation Rate | Maximise your transport loads |

| Integrated Transport Calendar | Easy to plan Transport with Project Dates |

| 3D Colour Coded Visualisation | Easy to know the exact status of every element |

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Wiki

For full technical details on the IMPACT Precast Transport Planning module please visit the IMPACT Wiki by clicking here.

IMPACT Blog

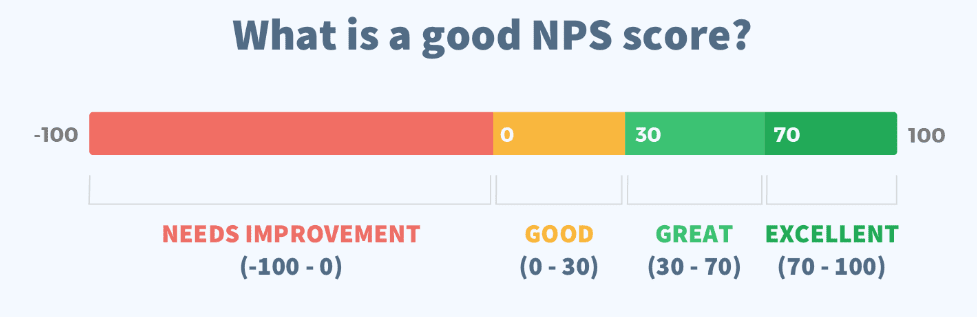

Net promoter score (NPS) and customer testimonial – IMPACT Precast Software

A small snippet of the customer testimonials we got through the NPS (See the rest at the end of the article)

- “Very useful software”

[…]

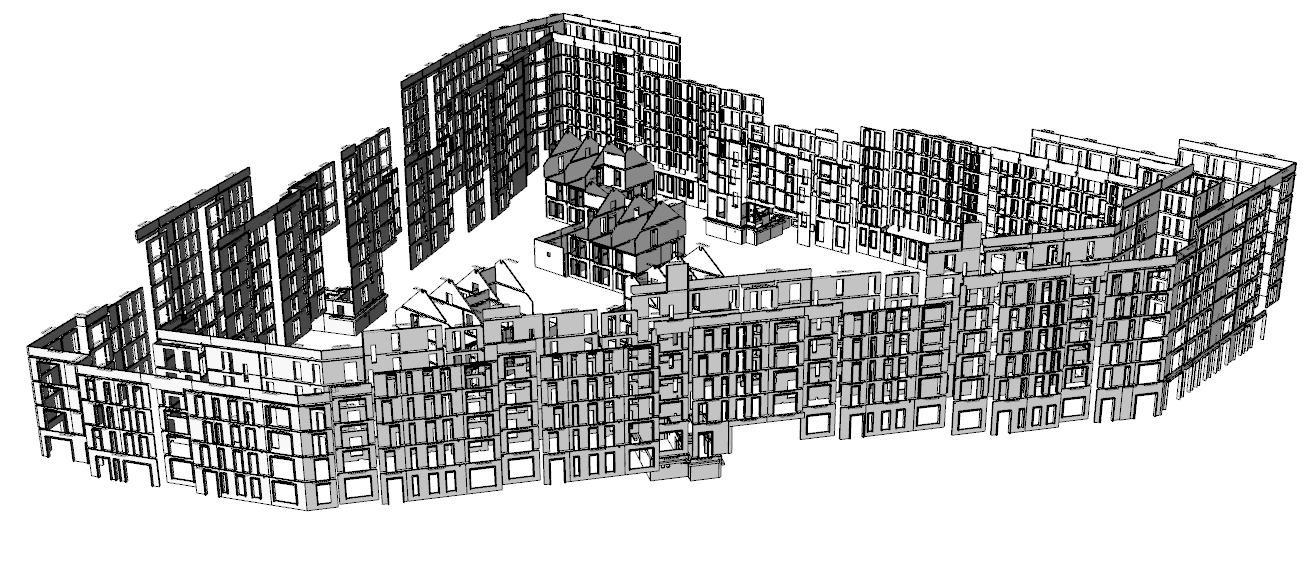

A LOT of IMPACT Precast Elements in Revit

Over the years

Developing Software for the building industry for more than 40 years has given us here at StruSoft a lot of time to gather […]

Precast 3D Modelling and Planning – TCT Implement Optimal System

Located in the northern part of rural Jutland in Denmark, we find TCT’s main precast factory. The factory makes a range of precast products such […]