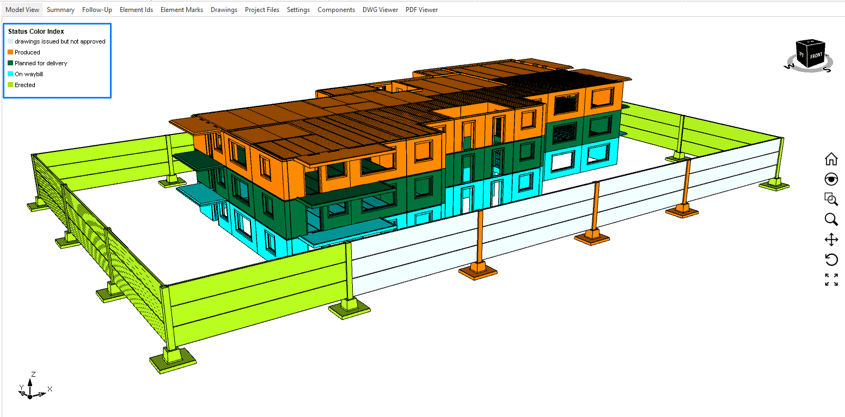

Precast 3D Modelling & BIM

Precast 3D modelling & BIM requirements are easily handled with IMPACT. The software allows you to create BIM models to Level of Details (LOD) 350 or 400 and quickly export your Precast Concrete Projects to IFC file format.

A big advantage with the IMPACT software workflow is that everything is in modelled in full 3D whether you are working through Revit, AutoCAD or BricsCAD.

You can create an IFC export immediately from the IMPACT 3D model, there is no requirement to develop an additional 3D model even if you are used to working in 2D CAD. This will save you a huge amount of time if you are doubling up work purely to satisfy a BIM requirement for your Precast Projects.

IFC Export

Industry Foundation Class (IFC) is a neutral data format to describe, exchange and share 3d model data and information typically used within the construction industry. IFC is the international standard for openBIM.

The IFC export to the required BIM level of detail (LOD) depends on which design workflow you are working with in IMPACT.

Find out more about IFC Export possibilities with IMPACT by clicking here.

Automated Precast Design

IMPACT helps you automate your precast design through tools we have developed for 3D modelling, design and detailing. IMPACT supports the 3D modelling for all the main types of standard precast structural elements.

As well as 3D modelling these automated tools within IMPACT include connection details, lifting/bracing and cast in materials. The software also performs automatic centre of gravity calculations.

Once you have developed your 3D model, the big advantage of IMPACT is that it can also automatically generate shop drawings together with all information and files stored centrally in the IMPACT database. This saves a huge amount of time with many Precast Business having to double their work by detailing 2D shop drawings with dimensions taken from the 3D model.

IMPACT generates automatic shop drawings based on predefined custom-made company templates. All components of the precast element, such as cast-in materials, connections, corbels, openings, recesses, etc. will appear with automatic dimensions on the shop drawings with user-specified view settings.

Find out more about automated precast shop drawings with IMPACT Revit by clicking here and for IMPACT CAD by clicking here.

As IMPACT is a central BIM database that connects data for all the elements of a precast concrete project. Real-time access for stakeholders at all levels enables greater control over overtime schedules, materials, and accuracy. This reduces costs, increases productivity prevents errors and conflicts.

Using IMPACT Revit even allows for collaboration on the Autodesk BIM360 platform.

Watch a Webinar about IMPACT Revit & BIM360

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Blog

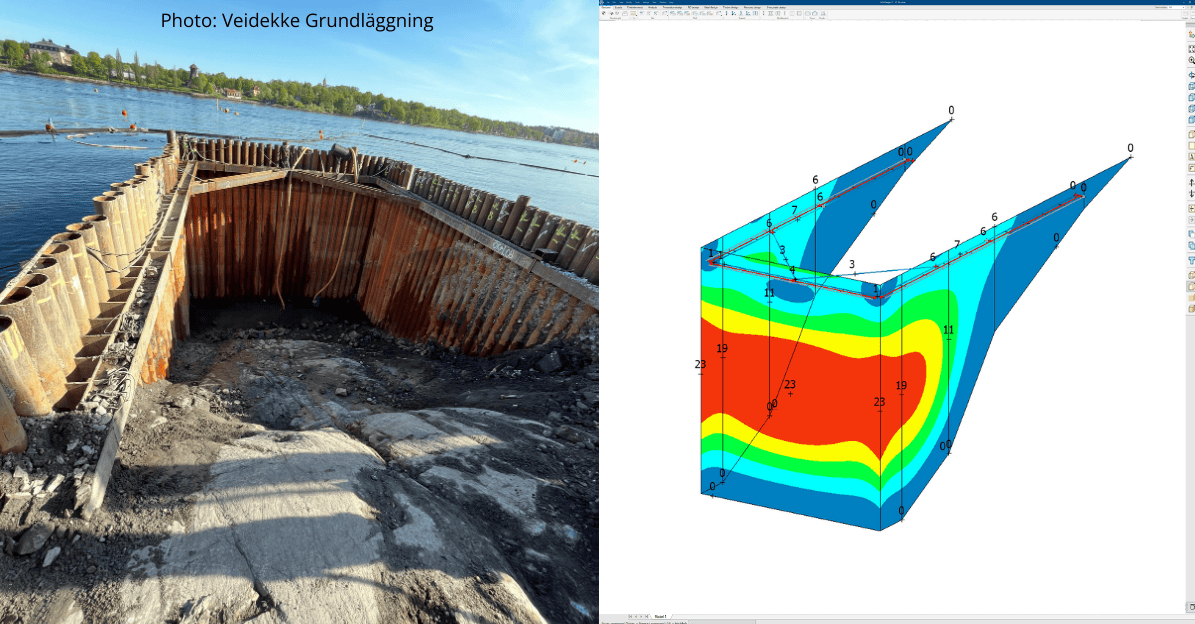

Veidekke Optimises Retaining Wall Design for Tunnel Outlet Using FEM-Design

A new stormwater tunnel in Stockholm, Sweden, known as the New Östberga Tunnel (NÖT), required complex geotechnical solutions at its outlet into Saltsjön. Veidekke Grundläggning, […]

Hollowcore Wall Panels Design

At StruSoft, we build tools that make precast design and production easier, not harder. That’s why we’re excited to introduce a new addition to the […]

IMPACT Environmental: Future-Proof Your Precast Concrete

Streamline Sustainability Compliance with IMPACT Environmental

The construction industry is facing a wave of new sustainability regulations, with stricter Life Cycle Assessment (LCA) […]