Precast Production Planning

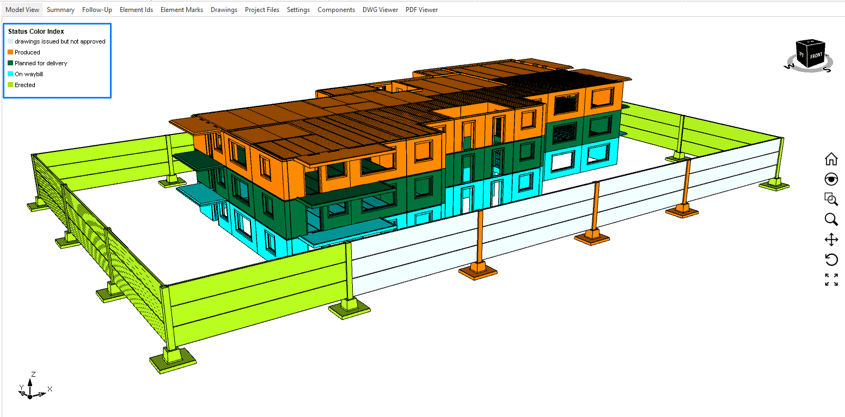

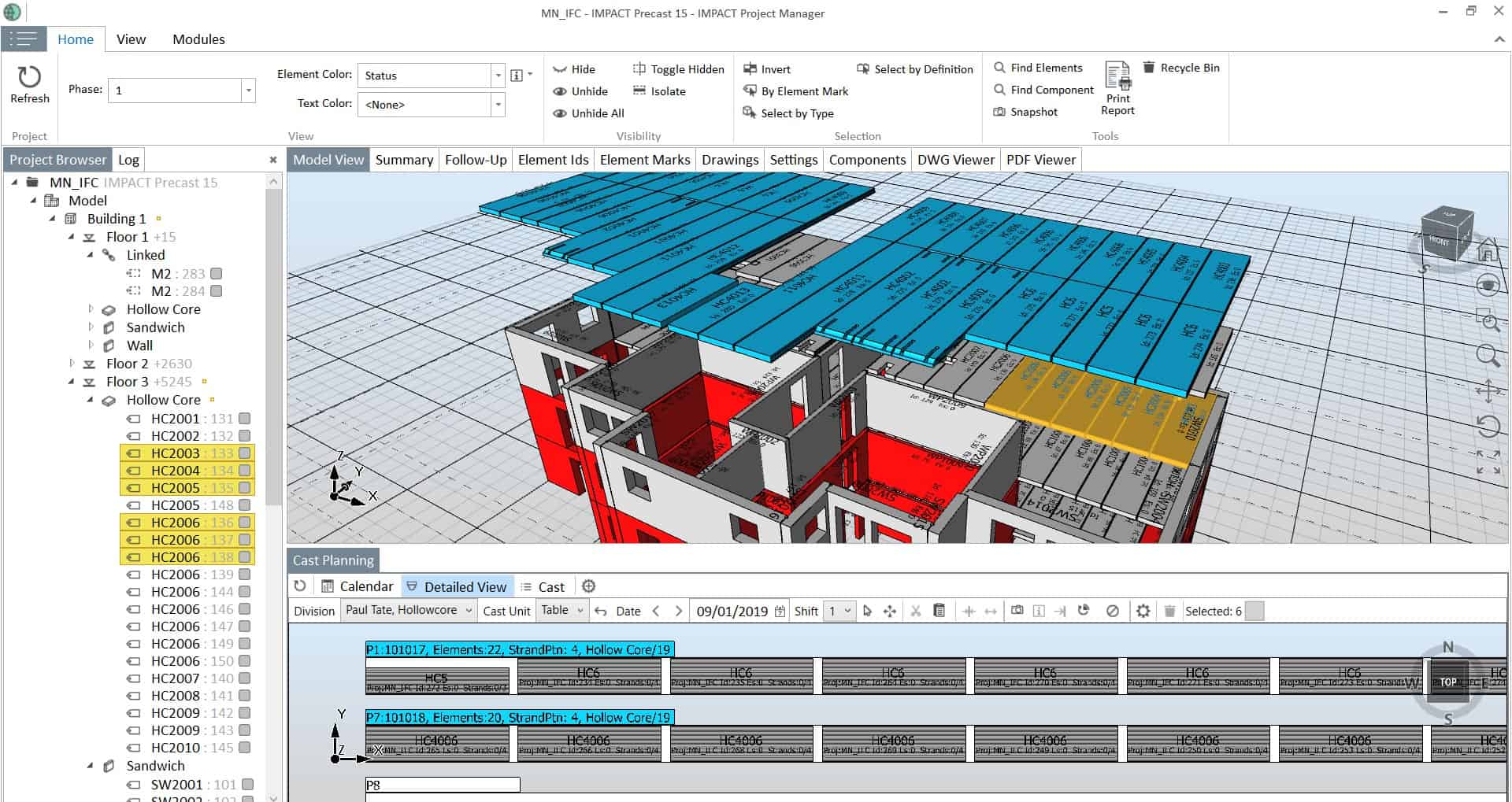

The IMPACT Precast Production Planning system helps you plan, keep track and know the exact status of any type of precast element, for any project, any factory, any mould/bed and any part of the process. It is an Enterprise Resource Planning (ERP) system developed specifically for precast production and it is unique that every aspect of your processes can be visualised in full 3D and in real-time.

It is fully customisable to suit your exact set-up in terms of factories; production halls through to individual production beds, casting tables and moulds. It is totally scalable and designed for small, medium and large precast operations.

It is flexible to help you plan any types of precast elements such as solid walls, sandwich walls, double (twin) walls, hollow core slabs, double tees, filigree slabs, columns and beams.

You fine plan in full 3D with the IMPACT Project Manager, which is very simple to use and you don’t require any 3D modelling skills or prior knowledge of modelling software.

Watch the Overview of IMPACT Production

One System for all your Precast Operations

Managing the day-to-day operations in a factory, optimising table/bed/mould space, ensuring production priorities are fulfilled are only a few of the jobs that a factory manager/planner must go through daily.

Using the IMPACT software through the user-friendly and intuitive interface, the above-mentioned tasks are performed efficiently and accurately. Working in the same SQL database allows you to take control of all day-to-day operations in the factory and know the exact status of every precast element you produce.

No more inefficient communications between different Stakeholders, no more having to email/call people to get information, no more managing spreadsheets that control different sides of the same project and are not fully integrated through all areas of the process.

Flexibility to suit your exact Production Setup and Headcount

The full IMPACT Production suite includes: Project Manager, Resource Manager, Cost Estimation, Transport Planner, Cast Planner, Erection Planner, Element Control and Custom Reports. These are also available as specific User modules to make the system as competitive as possible and suit your exact headcount.

Through the Project Manager you can view in full 3D a single project and drag and drop 3D model data for cast, stack and transport planning. There are built in PDF/dwg viewers for opening shop drawings and integrated calendars to support your planning workflow.

The Resource Manager gives you the ability to plan multiple projects and multiple factories for all precast element types.

The IMPACT Go mobile application allows unlimited number of people (with permissions) to scan QR codes, use the Element Control to change Element Status, add disorders/rejects, take photos and view all element info.

You also build up through the IMPACT SQL database a data set of entire lifecycle of all precast elements with the ability to sort and manipulate data to generate to custom reports to improve internal and external reporting.

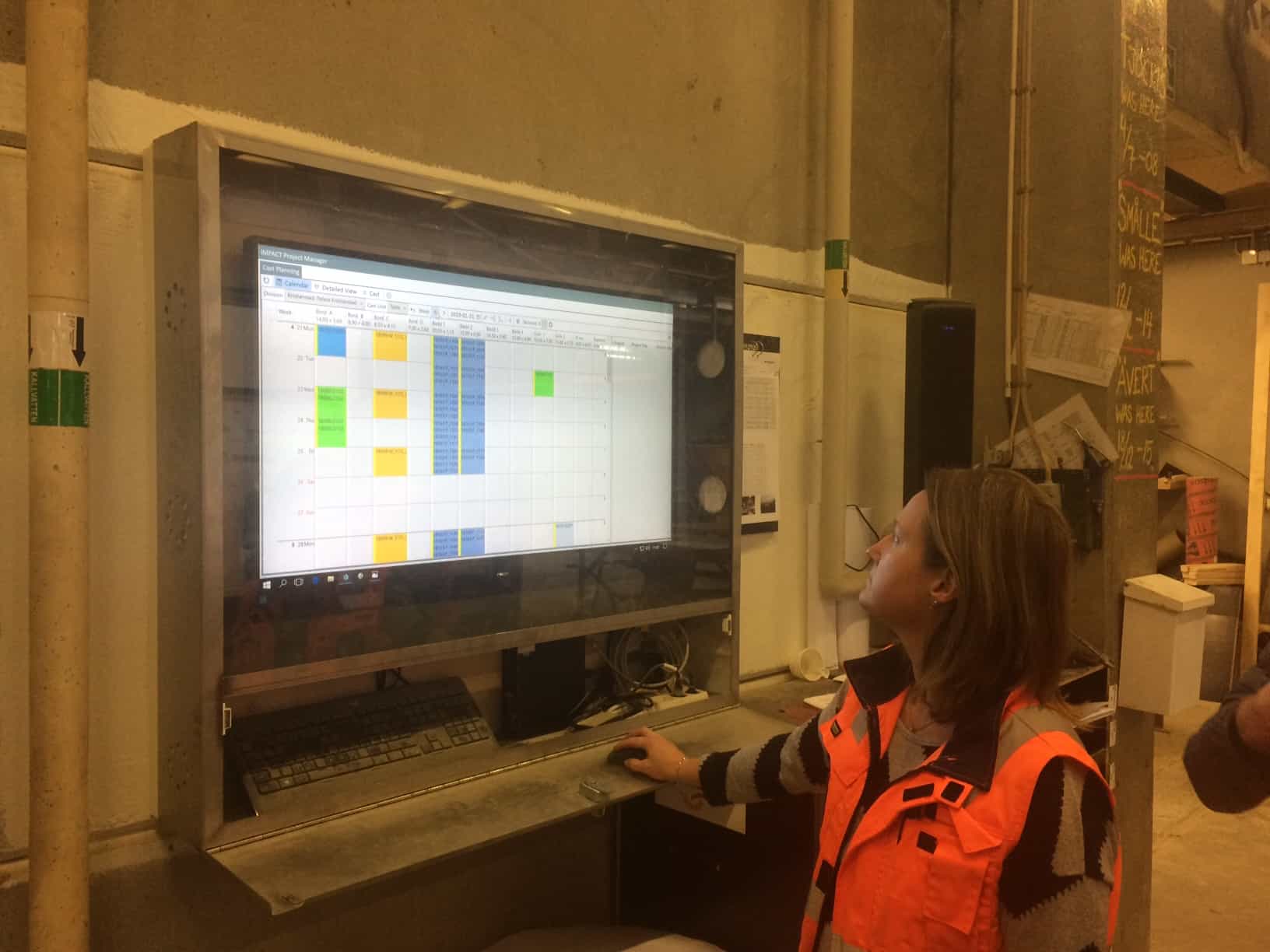

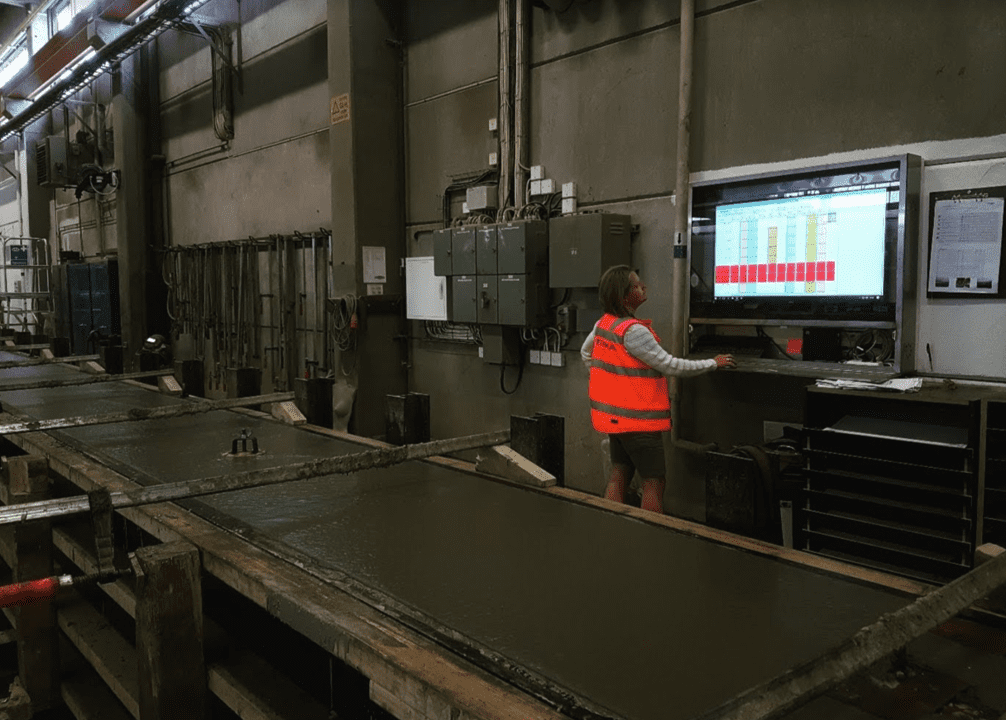

Production Screens in the Factory

Production Screen suites are available as an optional extra that include a single license of IMPACT Resource Manager and 3D Cast Planner specific for a factory. The idea being that the license is specific to the Factory and can’t be shared by other Users on the network to save interruption.

This allows your Factory Personnel to access precast production planning data through the Resource Manager in real-time. They have full visibility and usage of the calendars, 3D Cast Planner and can open/view/print PDF/DWG shop drawings (providing they have been mapped into the IMPACT database). This means that they can have planning meetings on the shop floor around the screen, know exactly what is planned for the day’s production, have all the drawings and save time having to come over to speak to people in your offices.

Why wait? Click to apply for a Free Trial of IMPACT and get started today!

IMPACT Blog

Hollowcore Wall Panels Design

At StruSoft, we build tools that make precast design and production easier, not harder. That’s why we’re excited to introduce a new addition to the […]

IMPACT Environmental: Future-Proof Your Precast Concrete

Streamline Sustainability Compliance with IMPACT Environmental

The construction industry is facing a wave of new sustainability regulations, with stricter Life Cycle Assessment (LCA) […]

Precast Detailing in IMPACT – A Webinar series of 3 (Watch it now)

Discover Precast Detailing in IMPACT by watching our webinar series.

We are happy to share the entire webinar series, Precast Detailing in IMPACT, as a […]