Steel Design 3D is a three-dimensional design module for FEM-Design. In this article, we will show off some of its key features to help you work optimally with FEM-Design.

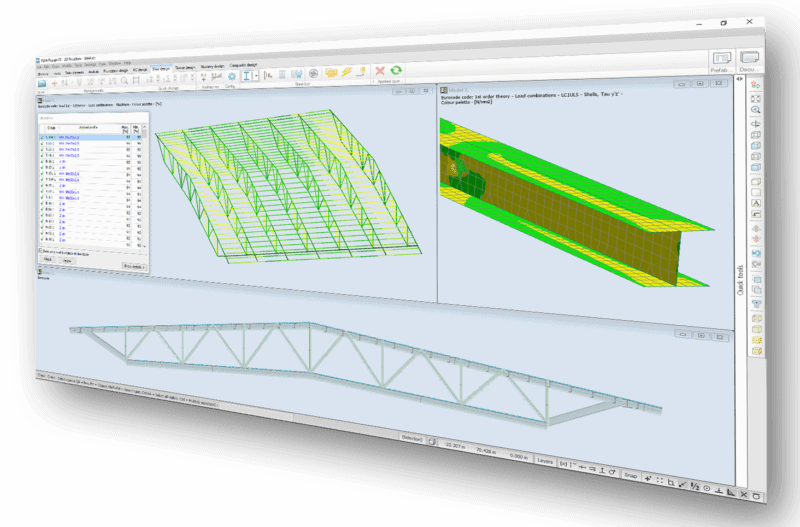

Steel bar design according to 1st and 2nd order theory

FEM-Design Steel Design 3D will facilitate a smooth experience for both 1st and 2nd order analysis. Using the Timoshenko beam theory FEM-Designs analysis results include contribution of shear deformations without any extra work. The software will automatically calculate imperfections according to EC3 5.3.2 (11) which gives you a simple way of carrying out a 2nd order analysis. This, together with great tools to exclude local stability shapes in shells and bars gives a powerful solution for all types of steel structures, even when you have a structure party stabilized with corrugated steel sheets or similar.

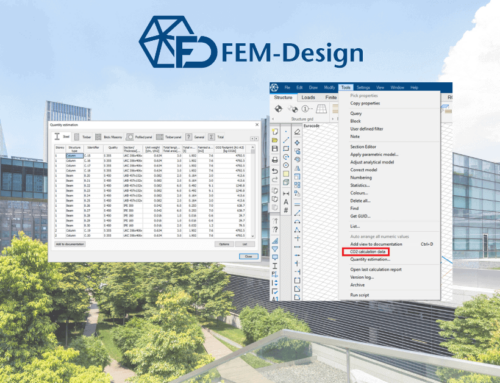

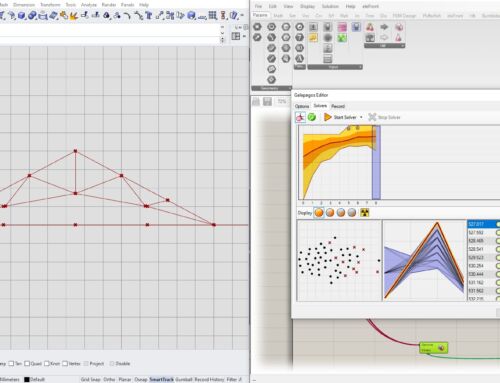

Auto design and design groups

When the analysis is finished, continue to design the members. Define the buckling lengths manually or let the software calculate them automatically based on the connecting members stiffness. By dividing the objects into different design groups, you can set section and utilization criteria to obtain a usable and quick automatic design of the members. All members within a group will be assigned the same section and you are able to select which type of sections you will allow for that specific group.

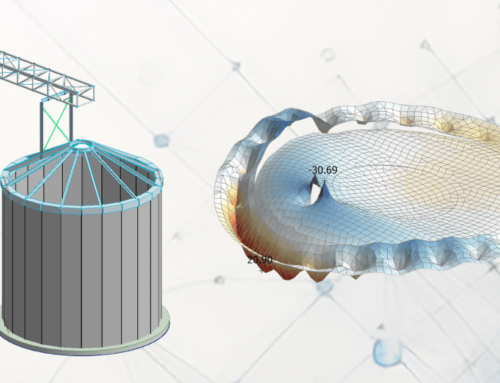

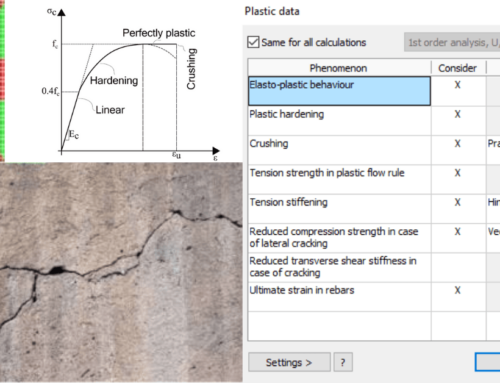

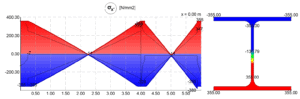

Steel bar plasticity

A new feature in FEM-Design 21 is the possibility to allow for plastic distribution of the stress over the steel section. This will allow for a more beneficial load distribution and will often extract more capacity from the overall structure. You are able to allow for plastic distribution for both ULS and SLS or only in ULS load combinations and the setting is object specific. This means that some objects can be calculated as linear at the same time as other objects will have a plastic distribution. This gives a great flexibility in situations where you, for example, want to consider the possible difference in section class between the members in the structure.

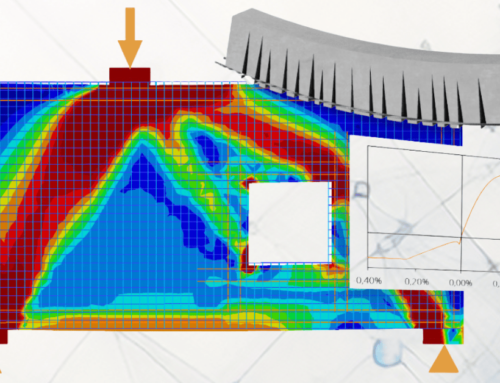

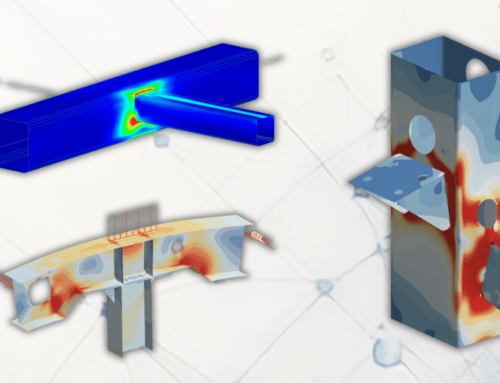

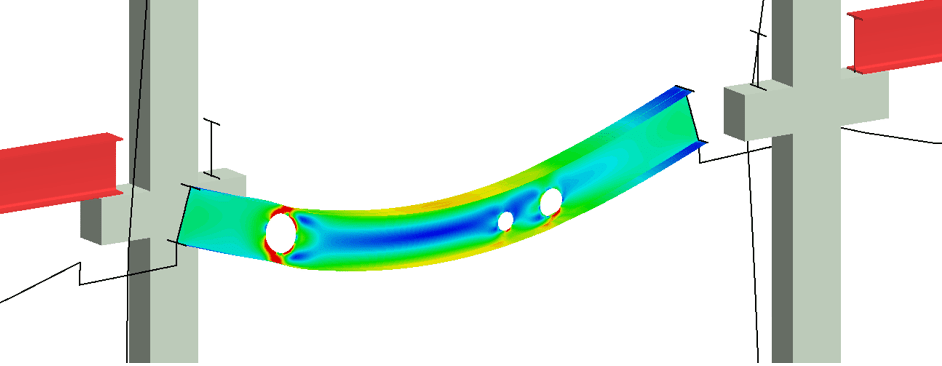

Bar to shell and design according to the general method

Another great feature in FEM-Design Steel Design 3D is the possibility to translate a bar object into a shell model. When the shell model is created you can add stiffeners, create holes, model the supports in a detailed way or make other changes to the geometry that influences the capacity. The object can then be design according to the general method described in EC3 6.3.4. This method uses the critical factor for the stability mode of the object and calculates a utilization from this. This is especially powerful in situations where you have a combined buckling that may not completely be covered by the usual design procedure in Eurocode.

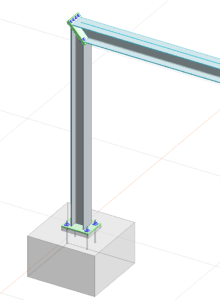

Steel joint design

FEM-Design Steel Design 3D can also design the steel joints in the structure. The calculation is based on an analytical approach where the joints are calculated according to Eurocode and SBI (Swedish steel construction association). These standard joints can be created in the global model and the stiffness of the joints can also be calculated and inserted into the model. This is a powerful way of working since the analytical approach to joint design is much quicker compared to a finite element approach. Is your joint not covered the standard library? FEM-Design 22, which is coming soon, will include a connection to IdeaStatica where you can make a more detailed joint design.

Fire design of steel members

You are also able to perform a fire design of the steel members. The software will calculate the temperature in the different sections in the model depending on the assumed temperature curve, the section exposure and the duration of the fire. The temperature in the section will then give reduction factors for the material properties. After this, a complete check is performed with the reduced material properties. This check will include all stability checks with regard to flexural buckling, lateral torsional buckling and so on, which will give you a much more detailed check compared to tabled values or other simplified fire design. Continue to design the fire protection of the members by adding gypsum boards, concrete, fire protection sprays or input your own specific fire protection product into the library. The software will then calculate the temperature in the steel section with regard to the defined protection.

Please do not hesitate to contact us if you would like a demo or trial of FEM-Design.

We will gladly help you out the best we can!

StruSoft Team