A new town hall will be built in Höje-Taastrup, Denmark. Engineer Nicolae Rares Nonu of COWI analysed the loads in FEM-Design, and documented in PREFAB which is a plug-in to FEM-Design. At his suggestion, we developed a solution to export structural data to Excel from PREFAB. Now he can continue to work in a simple way, save a lot of time and produce loads in order to calculate the amount of reinforcement.

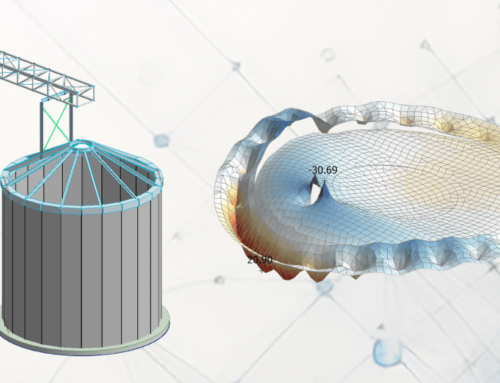

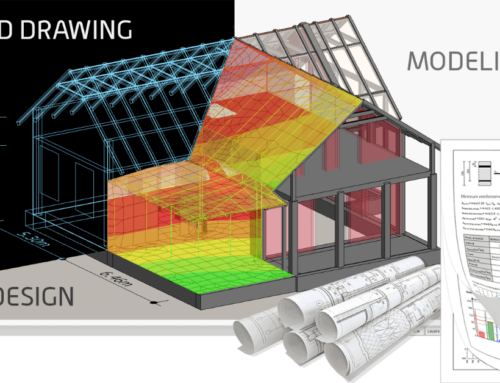

In Höje-Taastrup, just outside Copenhagen in Denmark, a new town hall is being built. With a square design and a beautiful silhouette the city, gets a new gem that can be seen from afar. The town hall has nine floors and a vertical atrium runs throughout the construction. Two lift shafts are an important part of the load-bearing part of the structure. In order to ensure stability in the design, analysis was carried out in FEM-Design by COWI, a well-known international technology company. They have delivered technical solutions for more than 90 years. In addition to the construction industry, COWI is also active in infrastructure, environment, energy and urban planning.

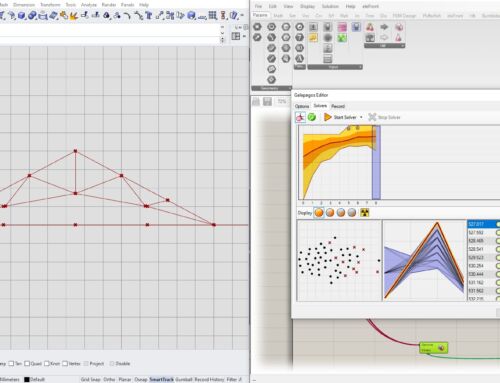

Fast modelling in FEM-Design

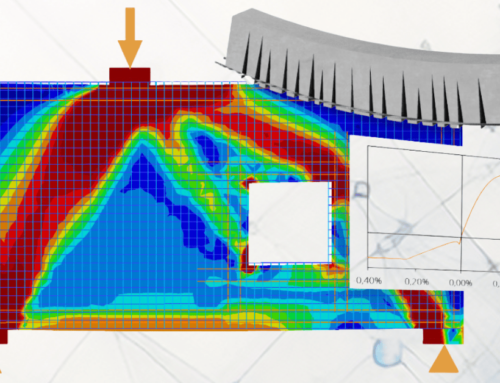

The first step was to develop a 3D model of the structure. Engineer Nicolae Rares Nonu at COWI in Denmark modelled the building in FEM-Design.

“It was quick, in a couple of days I had drawn up the construction from the ground up,” says Nicolae. We adjusted the model according to the Revit model, which we later gained access to. Then we carried out the analysis of loads, mainly self-loads and wind loads, which were used to design the right stability for the new town hall. The project included 25 load combinations”.

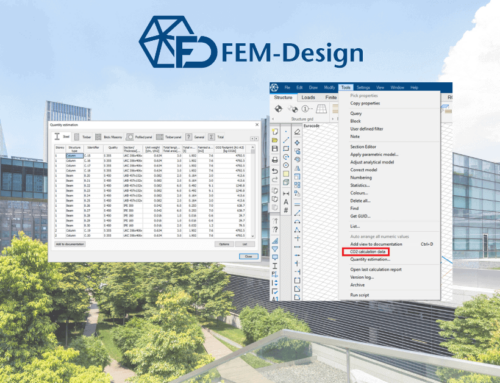

After the FEM analysis was completed, Nicolae used PREFAB to study the results. It is a plug-in to FEM-Design that shows the analysis results for prefab design.

“The information becomes easier to understand when presented graphically and can be exported to PDF. I don’t have to spend time producing the documentation myself, it is generated automatically”.

Pictures: PHL Arkitekter

Export Structural Data to Excel from PREFAB

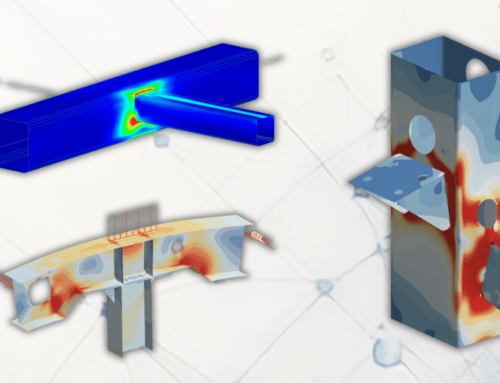

The town hall’s load-bearing frame in the central part is constructed with prefabricated concrete elements. To design the elements, Nicolae needed to obtain data on design forces from the model, important information that becomes the basis for calculating the amount of reinforcement. That’s why Nicolae asked StruSoft how the information from the PDF document could be further worked on.

“The document from PREFAB was quite extensive and had 300 pages,” says Nicolae. “It takes time to look through each page to get the data I need. Therefore, I asked Benjamin to see if he could come up with an Excel-based solution where data could be exported, which he did.”

It changed the way Nicolae worked.

“Now it is possible to export data from PREFAB to Excel and get a more flexible and easy way of working. I process data from the analysis, find data on forces and use data to perform calculations in different formulas. This makes it easier to design the reinforcement of the walls of the building”.

A strong information chain was built up where data from the model and analysis becomes editable and very useful in the project. From FEM-Design, via PREFAB to Excel. A flow that facilitates and saves time in the project that gives Höje-Taastrup a new impressive town hall.

You can find out more technical information about PREFAB on the FEM-Design Wiki by clicking here.

Pictures: PHL Arkitekter