Situated in southern Sweden, Starka AB, has three Precast Factories in Kristianstad, Arboga and Ängelholm. Two key improvement areas in the process at Starka’s Hollowcore Factory in Kristianstad were identified: first to eliminate human errors from manually marking out and second to speed up the process and with automatic weep hole drilling in the hollow core slabs.

The company was founded in 1930, is still privately owned and has grown to a turnover of €60 million with around 280 x Employees. Starka has around 50 x daily Users working with IMPACT, initially starting with IMPACT Design in 2011 and progressively implementing the entire IMPACT Production system from 2017. They produce a comprehensive range of structural precast concrete elements for buildings, including columns, beams, sandwich walls, solid walls and prestressed hollowcore slabs.

In 2020 Starka took the decision to invest in a new automated Plotter from Concore in Holland which also included an automatic weep hole drilling function.

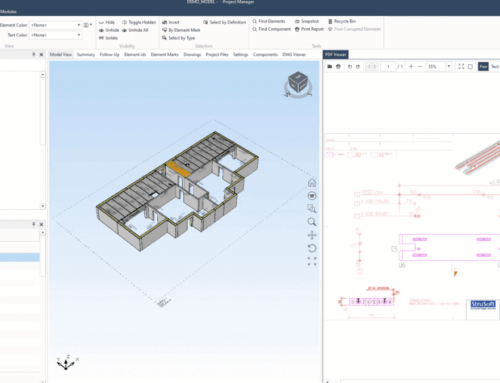

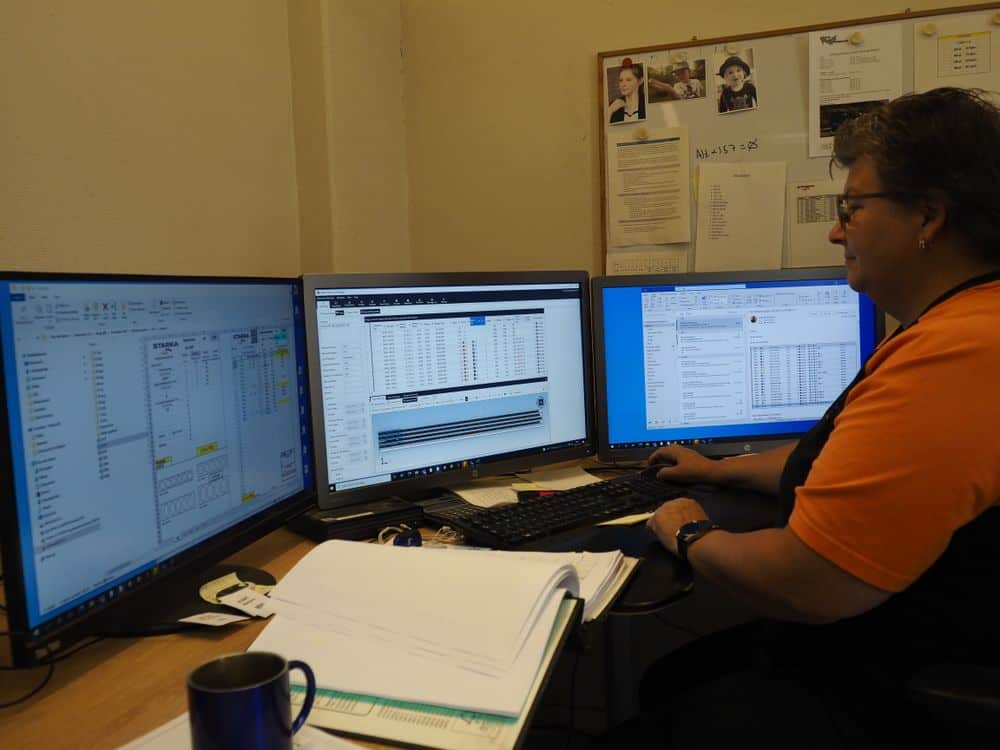

Starka engaged StruSoft from the start of the Project with their vision to keep the workflow exactly the same for the IMPACT Users. The main consideration being still able to use the IMPACT 3D Cast planner to export planned bed data directly to the Plotter through a WIFI connection from the office into the factory. The detailing for the weep holes was also a major consideration, as having previously been a manual drilling process, were not specified on their shop drawings.

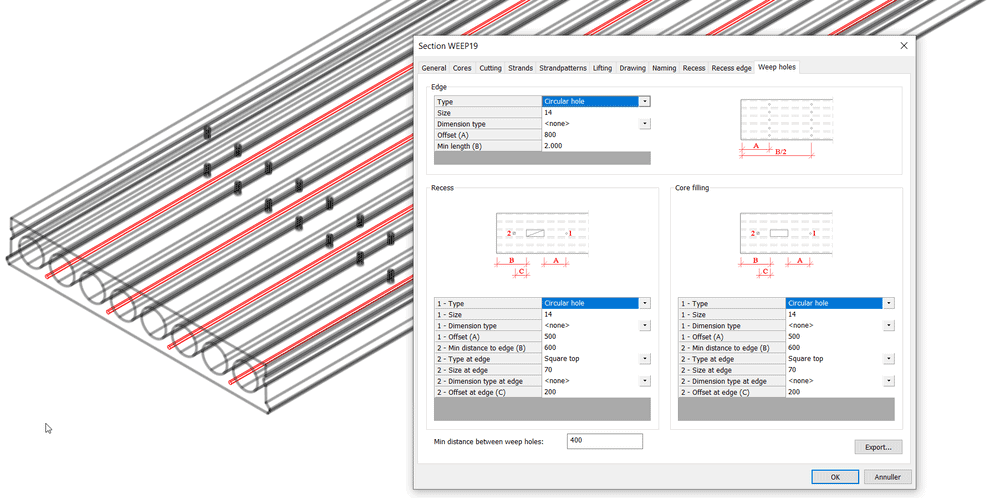

StruSoft developed a new design tool within IMPACT Design specifically for weep holes in order to automatically detail them in the hollow core slabs to then be able to export accurate data to the weep hole drilling unit.

The complexity of developing an automated weep hole detailing was to account for the vast array of possibilities of weep holes with the different hollowcore slab depths and different internal core possibilities further compounded by potential core fillings and recesses in the slabs.

To overcome this and keep the workflow as simple as possible for the Detailers, StruSoft developed a categorisation of weep holes into 3 x different types of: “Edge”, “Recess” and “Core Filling” within IMPACT Design. Company specific weep hole standards were also created in IMPACT and a new weep hole ribbon command developed for the IMPACT Design Users.

You can read more about the weep hole development on the IMPACT Wiki here: Weep holes for Hollow Core.

The biggest challenge StruSoft faced was to find a standardised data file format to work seamlessly between IMPACT and the Plotter to be able to keep the User workflow exactly the same and ensure accurate data transfer.

It was agreed to use the JSON data file format and both StruSoft and Concore made new software developments to be able to export and import the JSON data between IMPACT and the Plotter.

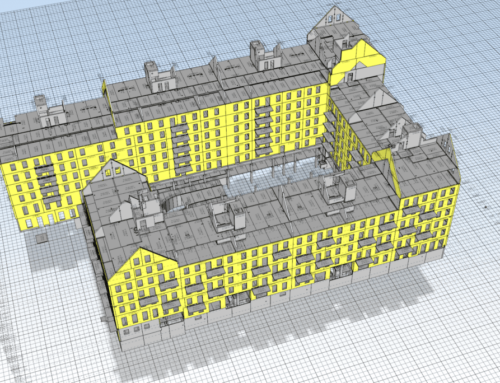

For the IMPACT Users the workflow is exactly the same using the 3D Cast Module and once the hollowcore bed is planned the User simply right clicks on the bed and selects the export to Hollowcore Plotter.

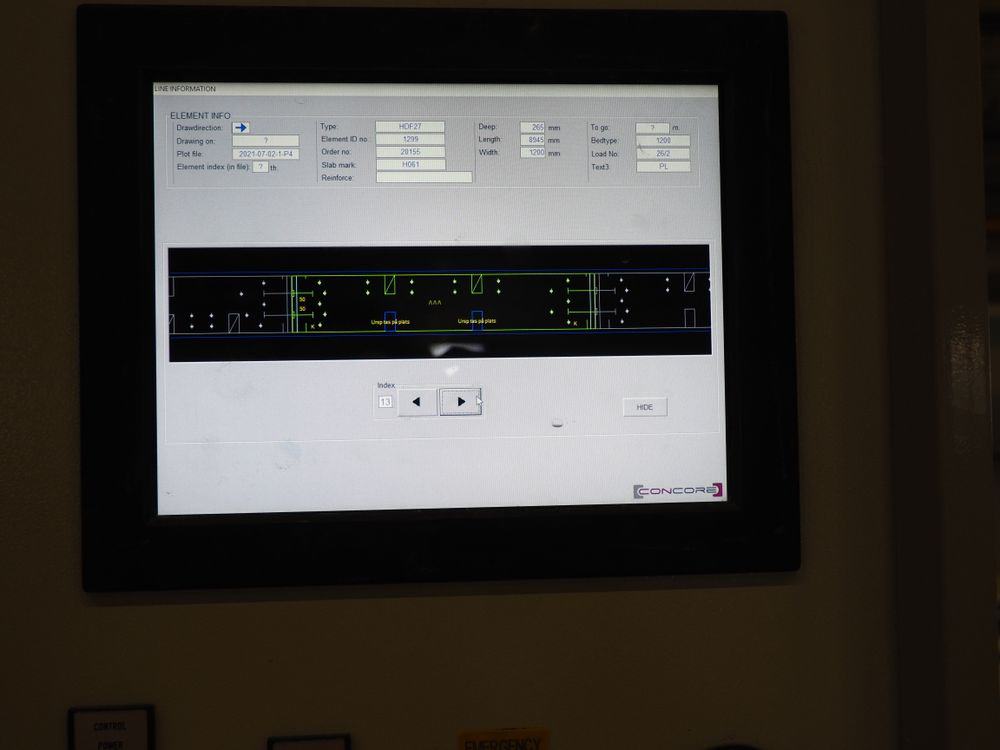

The JSON files with all the data for the entire bed and individual slabs are then sent to a specified folder and sent by WIFI to the Plotter in the factory. The Plotter has a User interface and PLC Screen to download the JSON files and view the bed and detail on the individual hollowcore slabs.

The commissioning was compounded by the Covid pandemic situation in 2020 and the Concore Engineers were unable to travel to Sweden, but it is testament to the thorough investigation, skilled engineering and close working collaboration to the three companies that the Plotter was able to “plug and play” and the data connection with IMPACT worked seamlessly.

Watch the video below of Starka’s Plotter in action.

According to Planning Manger, Camilla Nilsson, Starka are now reaping the rewards of the investment in the Plotter and the new functionality developed within IMPACT.

“…we are delighted with our investment and the support from StruSoft and Concore. We have reduced marking out geometry errors to zero, the working environment in the factory has improved dramatically and we are saving considerable amounts of time in the process by drilling the weep holes automatically directly behind the extruder instead of cutting and lifting each individual hollowcore slab and moving it to the old drilling unit in the factory.”

The new updates to connect to Concore Plotters are available to existing IMPACT Users and existing Concore Plotter Users can also get a software update from Concore should they wish to start working with IMPACT.

If you would like to find out more about IMPACT or are looking at a developing more automation in your hollowcore factory then please feel free to get in touch and we would welcome the opportunity to see how we can support you.

Article by Paul Tate, VP | Marketing.