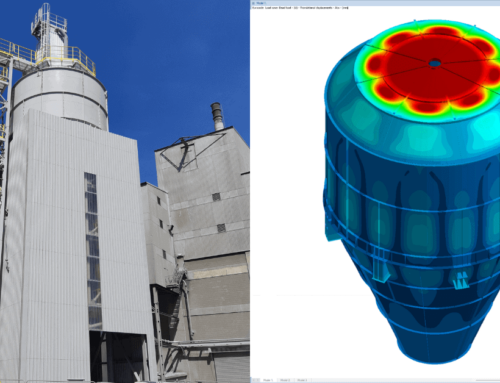

The structural design company SWETCH is currently developing a steel frame structure for the home stadium of the Bodø/Glimt football team – The Arctic Arena.

Project overview:

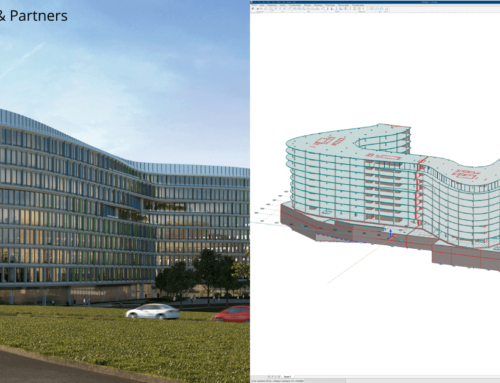

The Arctic Arena will be a modern, sustainable facility accommodating 10,000 spectators across 18,000 m². Designed to endure the demanding Arctic climate — snow, wind, and extreme cold — the stadium embodies both resilience and innovation. Its diamond-shaped silhouette creates a striking architectural identity, with a roof and façade composed of a series of geometrically arranged panels that achieve both symmetry and visual dynamism. This architectural and structural design concept has been developed by Nordic Office of Architecture in collaboration with ARUP Sport.

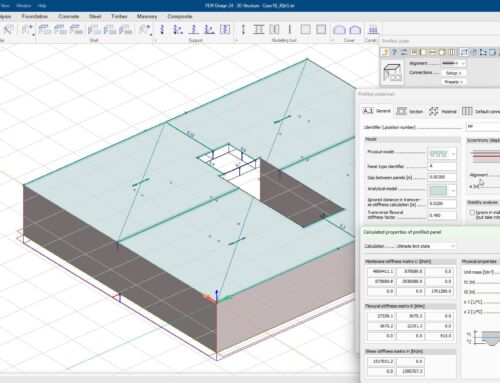

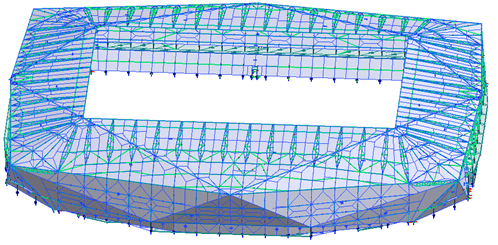

SWETCH was responsible for developing the project’s design stability model. By leveraging FEM-Design’s precise and efficient geometry input tools, it was possible to model more than 7,000 bar elements with remarkable accuracy and speed.

The Arctic Arena. The image is courtesy of Nordic Office of Architecture.

FEM model of The Arctic Arena. The image is courtesy of SWETCH.

The main engineering challenges:

Complex geometry

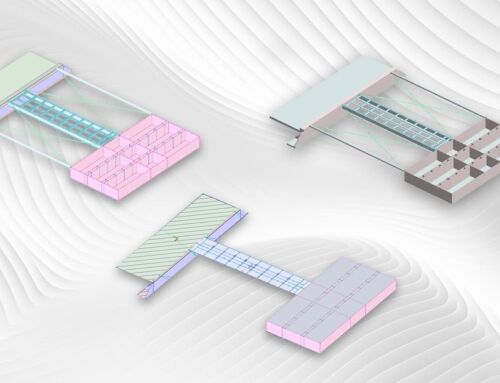

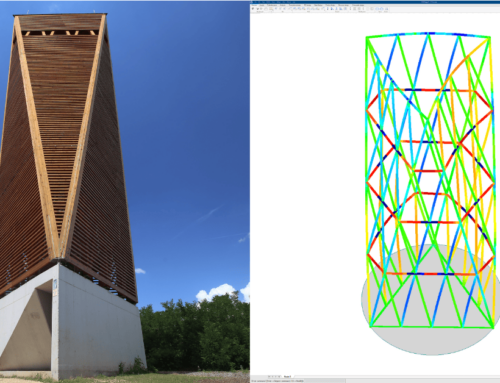

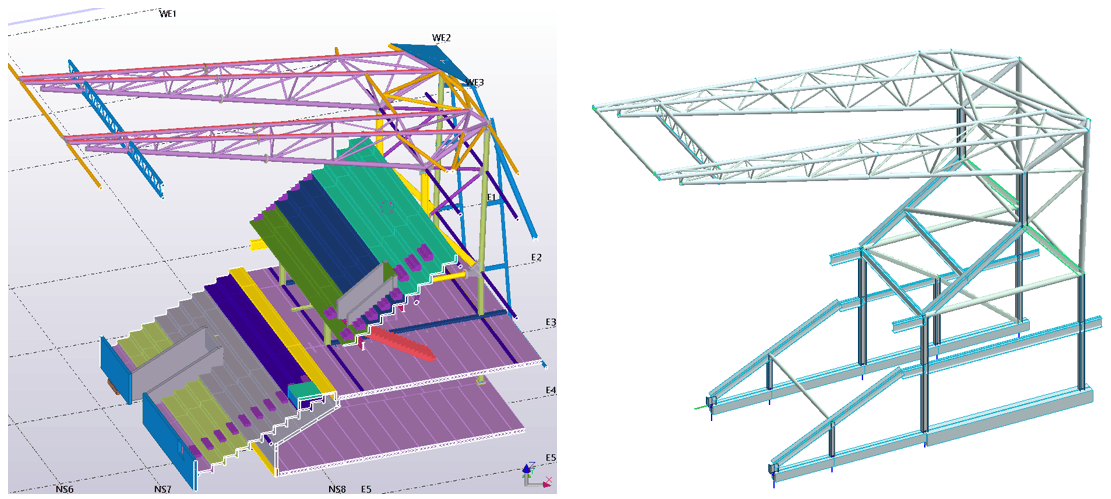

The stadium’s structural scheme consists of a steel frame, including long-span cantilever roof trusses, precast slab diaphragms, and precast tier elements.

While FEM-Design is commonly used at SWETCH for the design of prefabricated concrete structures, the Arctic Arena project demonstrates its strong capabilities in modelling and analysing complex steel bar assemblies as well.

Multiplanar trusses with complex geometry are located at each gridline. None of the truss elements connect at right angles.

Typical section of Arctic Arena. The image is courtesy of SWETCH.

Comfort assessment

Deflections of roof trusses and floors, and floor dynamics, have been assessed to comply with the relevant criteria, ensuring crowd comfort and safety.

Thermal effects

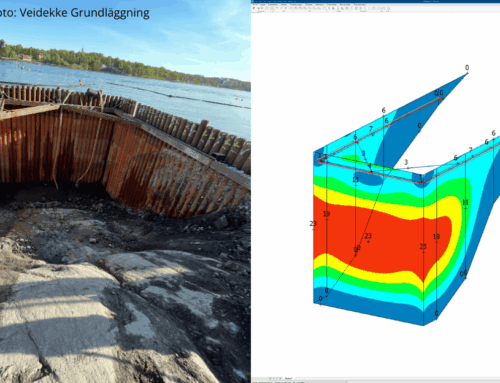

Structural steelwork is not insulated against changes in ambient temperature, and thermal effects have been considered in the analytical model. To allow movement between concrete elements, movement joints in concrete diaphragms are introduced, but forces in some steel elements exceed 600kN from thermal effects.

Reconciliation of FE models

To ensure correlation between the concept and design models, the geometry, forces, reactions, and deflections of the SWETCH FEM-Design model were compared with those of the ARUP Oasys GSA model. The two models show sufficient correlation.

FEM-Design’s role for the design of the steel frame structure

FEM-Design’s Steel Design module was used for the first iteration of steel profile dimensioning and control.

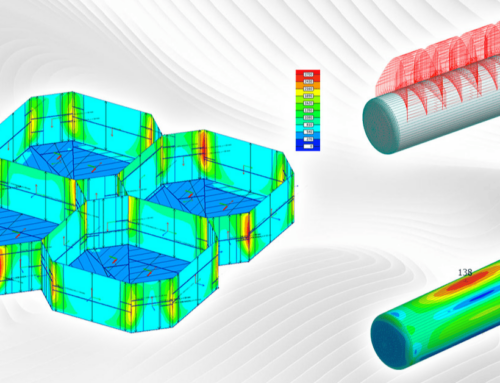

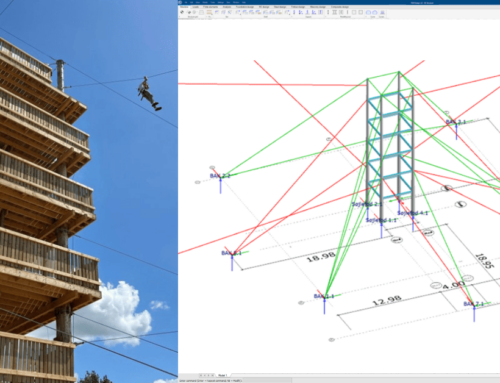

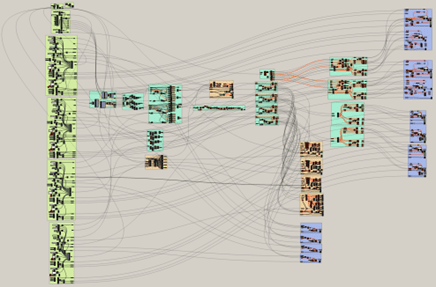

Using the FEM-Design API, SWETCH has developed a Rhino Grasshopper script that links the FEM model to the Tekla Structures model.

Rhino Grasshopper script of FEM-Design and Tekla link. The image is courtesy of SWETCH.

Steel connection design

To analyse the connections between trusses and frames with different geometries and forces, the engineering team used FEM-Design’s integration with IDEA StatiCa.

About SWETCH:

SWETCH is a civil engineering company with a team of 70 engineers, working on some of the most challenging public and industrial design projects in Sweden and Norway. Founded in 2015, the company specialises in the design of reinforced concrete and steel structures.

Edgars Zelčs is Head Engineer at SWETCH. He has over ten years of experience in designing complex structures, along with extensive expertise in using FEM-Design for the creation and quality control of finite element (FE) models.

The Arctic Arena project started in 2024 and is expected to finish construction at the end of 2027.

See below the project team:

Frame design: SWETCH

Manufacturing, assembly: Nordec, Jaro

Engineering consultant: Arup

Customer: Bodø/Glimt FC

Developer: Consto

Architectural design: Nordic Office of Architecture

Count on FEM-Design for designing a steel frame structure

The Arctic Arena project highlights how designing a complex steel frame structure becomes significantly more efficient with the support of precise and intuitive modeling tools. With FEM‑Design, SWETCH was able to manage thousands of bar elements, optimise structural stability, and deliver a robust model capable of withstanding the demanding Arctic climate.

If you’re looking to achieve the same level of accuracy, speed, and confidence in your own projects explore what FEM-Design can do for you.