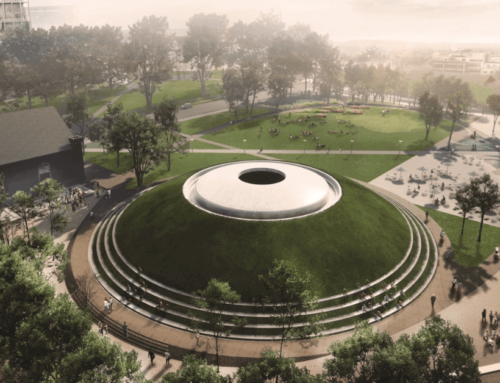

At the Universeum Science Centre in Gothenburg, a new dome is now being built where visitors will be offered movie experiences about nature and technology.

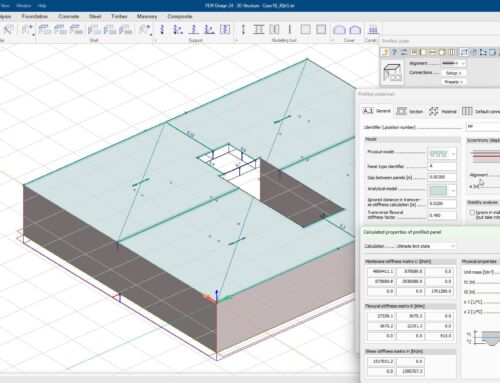

MW Byggtekniska has made advanced analysis to design Universeum’s new hybrid dome’s construction according to the three different materials: concrete, steel and timber with the help of FEM-Design.

“Without FEM-Design, we would not have taken the project”, says Stefan Kastberg at MW Byggtekniska.

Universeum in Gothenburg is a goldmine of experiences and insights for the curious person. A place for public education and a science center for natural science, technology and sustainability. A visualization dome is now being erected on the roof of Universeum to give visitors new experiences.

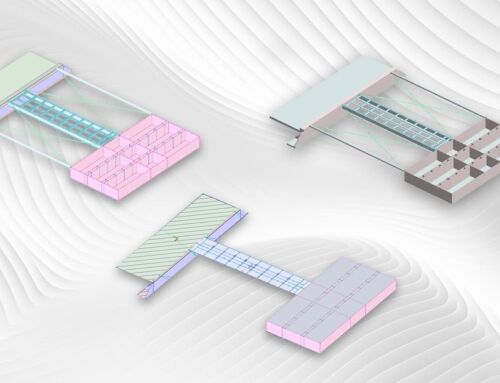

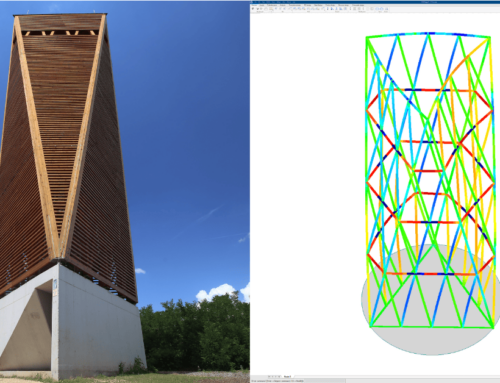

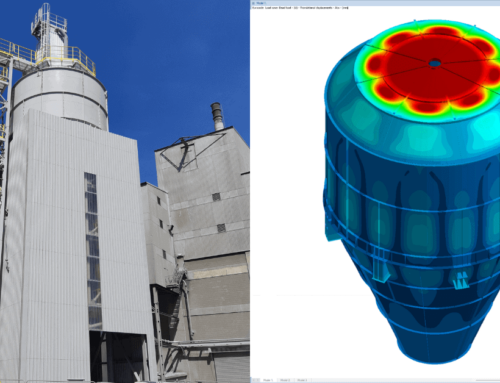

The dome resembles a giant sphere and measures 27 meters in diameter. It consists of an outer shell of 84 assembled triangular timber elements held together by a steel structure. Inside the dome, a giant film screen is placed in a hemispherical shape where visitors can experience visualizations and animations for various subjects.

The engineering company MW Byggtekniska in Varberg has drawn up construction documents for both the dome and the footbridge with the connecting stairwell and lift. MW Byggtekniska works with building construction mainly for municipalities and private actors in the construction industry.

Vibrations due to wind loads can disturb the movie experience

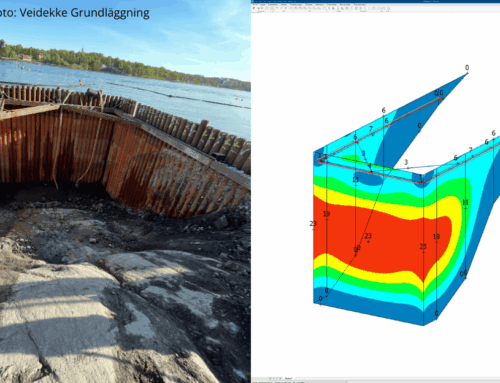

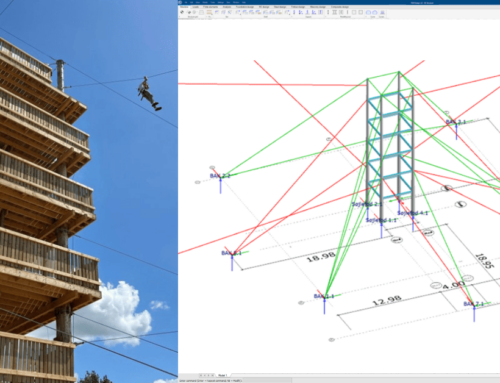

The dome has a vulnerable location in the high placement on the roof and urban surroundings. This brings a constant influence from weather and wind.

“It is mainly the wind loads, especially gusts of wind, that can create vibrations and affect projectors and equipment”, says Stefan Kastberg at MW Byggtekniska.

How much movement can be accepted to avoid interference with the projectors and screen? To answer the question, the engineers have made calculations in FEM-Design and arrived at a stiffness in the construction where the vibrations are acceptable and will not affect the experience of the visitors.

The dome is exposed to the influence of weather in the upper part. It also experiences deformation in the lower part caused by the self-weight of the construction, where the slab protrudes several meters out as a cantilever. Therefore, it was important to produce a design that takes deformation into account and here FEM-Design was a necessary tool to produce an acceptable result.

Several materials in the global calculations

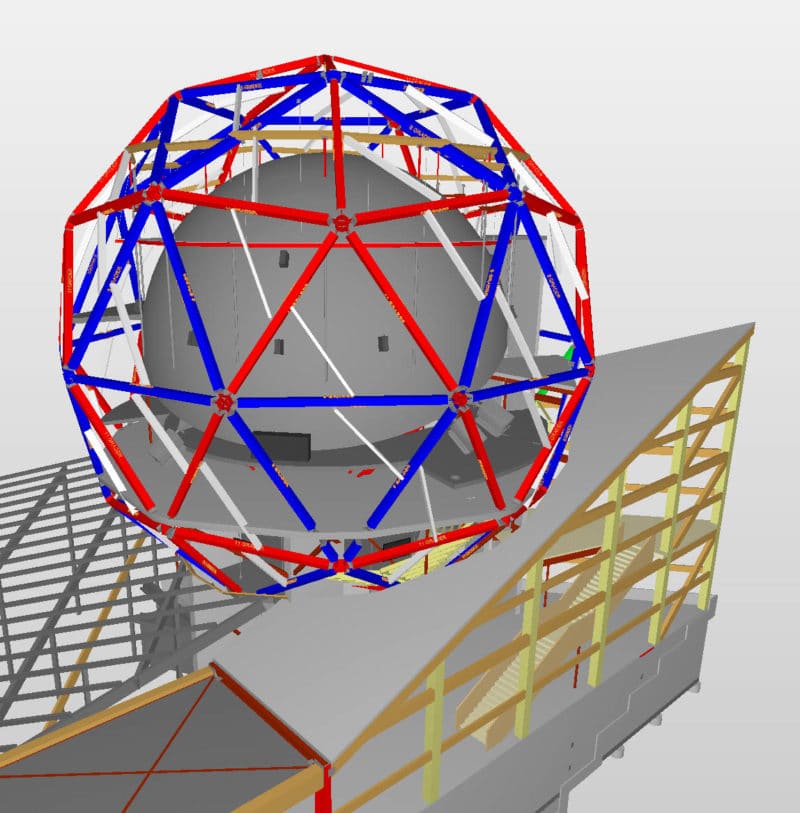

The dome is built with several materials which complicates it further. The outer shell consists of CLT panels and steel beams and underneath that a construction with both concrete and steel.

“It is an advantage that we have performed a global calculation that includes all the materials together…”, says Stefan, “…the materials have different properties and stiffnesses and it is important to get an overall understanding of the construction and not deal with each material separately. In FEM-Design, we can study how the different materials deform together and evaluate the result.”

Stefan used the CLT module in the project.

“The CLT-panel design has worked well, he says. I think it is good to be able to handle different materials and design them in the same model.”

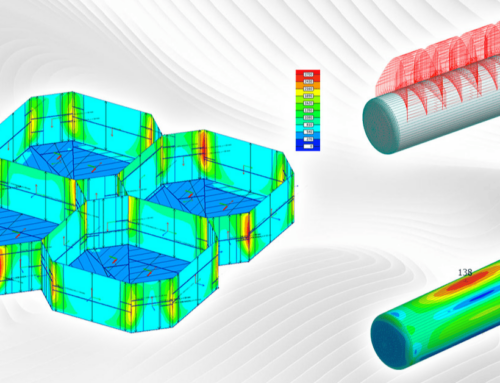

It is not only global analysis that was performed. The engineers also studied local forces in the elements.

An example is the joints for the steel structure, where they obtained the forces and could carry out a design with regard to the flow of forces in the structure. Everything to get a robust construction.

“We check at the local level to see how the forces distribute and if it seems reasonable, so that we don’t risk getting incorrect results”.

Difficult to complete the project without FEM-Design

The project has thus had a variety of challenges, one of the biggest was being able to solve all problems in one software.

“If we didn’t have FEM-Design, we probably wouldn’t have taken the project, Stefan notes. It would been too many uncertainties with potential risks. For example, a too conservative design which had affected the project’s finances with a higher material cost.”

But thanks to FEM-Design, the engineers were able to handle the challenges and have produced a durable and rigid construction. An important step in the project to facilitate new experiences for visitors in Universeum’s new dome.

© Love Janson

Main Image Credit: “Wingårdhs”