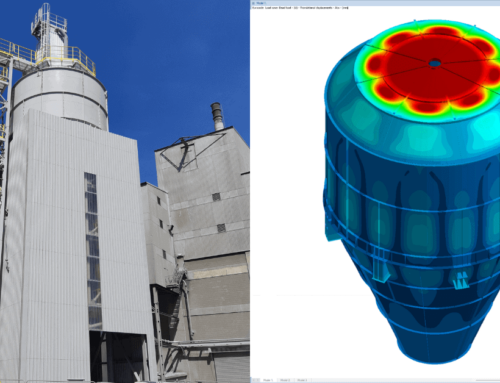

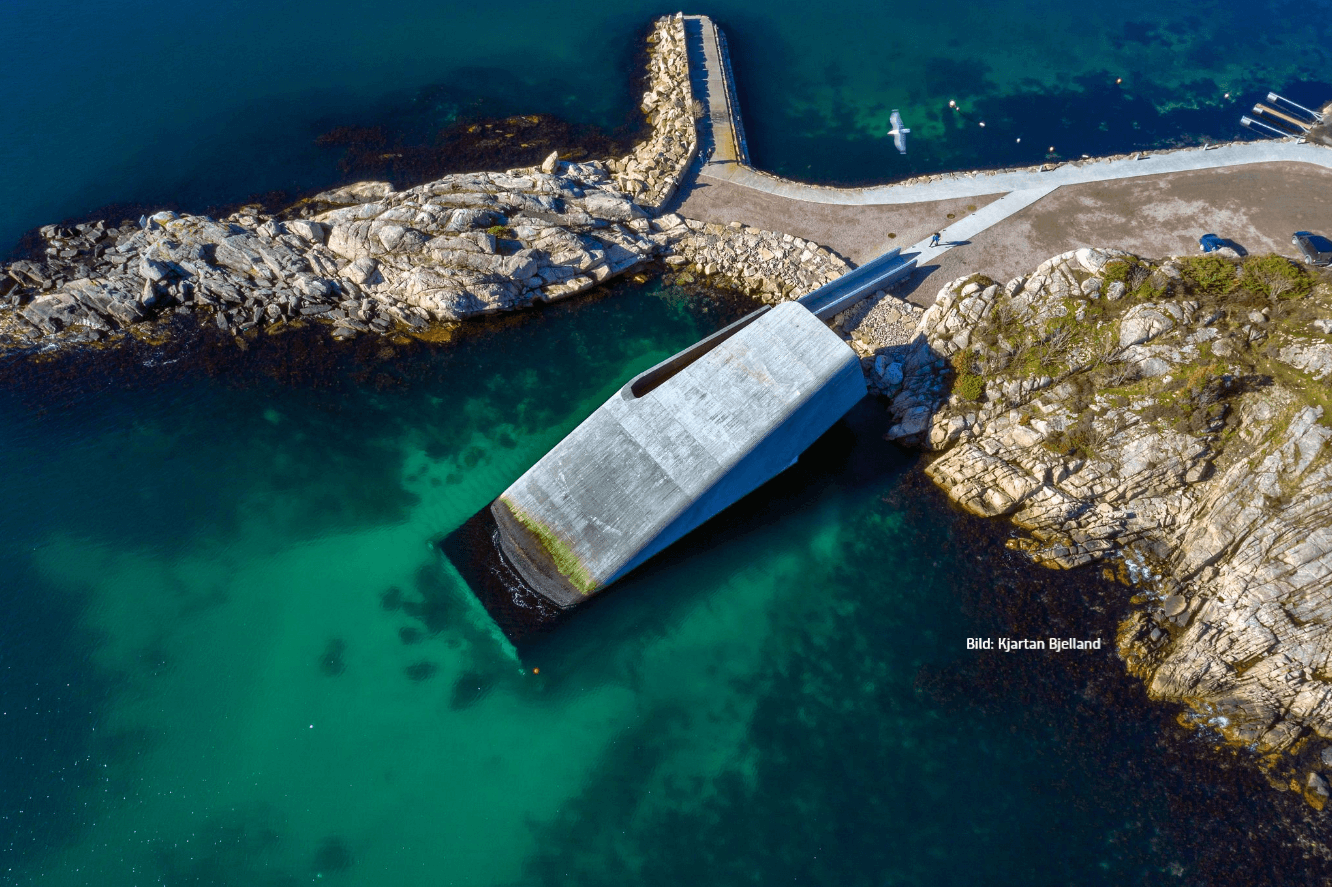

It seems as if the concrete structure has slipped into the sea. The underwater restaurant “Under” in southern Norway looks like nothing else and offers the guests an incomparable view with fish swimming through the fjord. The project is spectacular, to say the least, and had several challenges in which FEM-Design played an important role.

Restaurants are often located high and offer the guests a wide view. In the southernmost part of Norway, the guests are instead allowed to enjoy the meal below sea level with a large window facing fish and sea life. It is at least a great experience. The underwater restaurant “Under” has room for 100 guests and was inaugurated in 2019. To design and build an elongated shape, several issues must be solved that put technology and knowledge to the test.

Seabed Loads

The restaurant’s large, submerged, the concrete structure is not subjected to ordinary wind loads, but by completely different forces.

“Only waves and tides are important and it was a big challenge in the calculations, says engineer Terje Raanes from the Norwegian architectural and engineering company Asplan Viak.”

Terje is a regular user of FEM-Design and, together with his employees, has carried out extensive calculations. Because the shape of the restaurant is so special, one could not benefit from knowledge from projects with a sea connection such as offshore or platforms. It took a lot of new thinking.

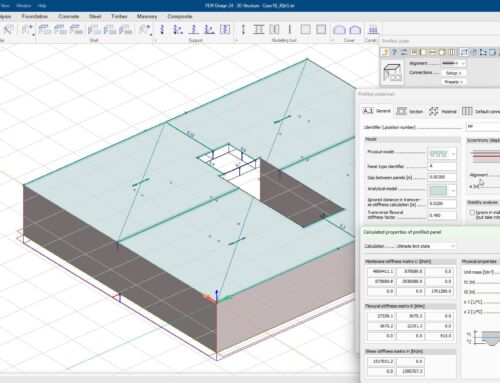

“Tides are a static load that we included in FEM-Design. But it was not as easy in the case of the waves and in Norway, there is no standard for which wave loads can be analysed in a construction.”

The weighing loads were developed by a consulting company with specialist expertise in the marine sector. The huge amounts of data were then imported into FEM-Design with a script that Terje and his co-workers had produced. In the program, the wave loads were transformed into point loads on the construction. The main calculation file in FEM-Design contained up to 1200 load combinations based on the eight worst wave types that have the greatest impact.

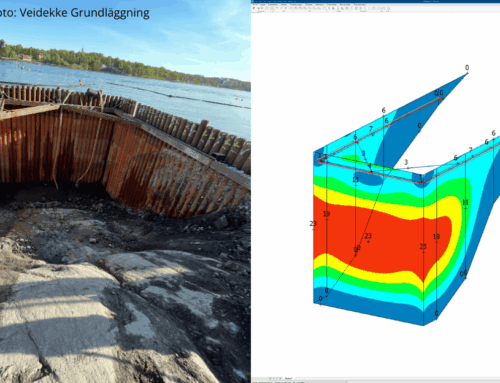

“A very complicated task where we spent time finding the right way of working, says Terje. After that, it was easy to run the analyses and extract the results in the usual way. Each analysis took approximately six hours. The restaurant’s outer concrete shell was cast in several stages on a large stand. It happened on the other side of the bay where the restaurant will be located. But the most critical thing was when the finished concrete body had to be transported on the fjord and assembled on-site because there were many factors that could come into play. On-site, it was then anchored on a number of pillars on the seabed.”

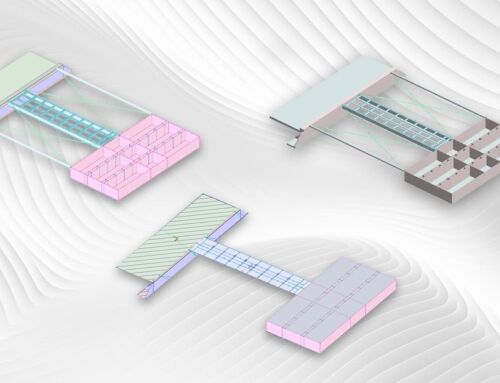

“In total, four different calculation situations were required to obtain the right dimensions, says Terje. We took into account the empty concrete shell. We also took into account the structure during its construction, including the centre of gravity calculations, as it was built horizontally. In addition, we took into account the complete restaurant with the concrete body and finishing, ventilation, and other details. The fourth calculation, to transport the restaurant to its place, was made in another program.”

Photo by: Kjartan Bjelland

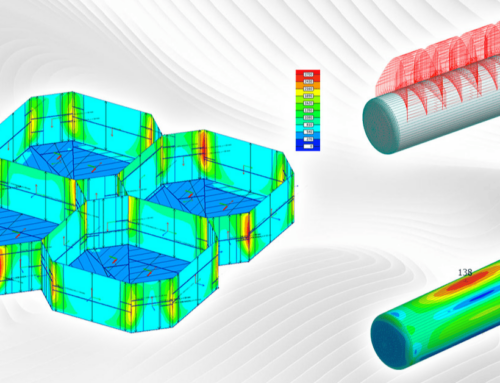

Analysis of Bottom Pillars and Deformation

The concrete structure rests on two horizontal and eleven vertical steel columns, which are mounted on the seabed. The dimensioning of the pillars is also done in FEM-Design. Another task is to analyse when large waves strike the structure and how the structure moves. Deformations that can occur in the concrete were also analysed. The floor in the restaurant consists of a concrete slab that bends up at high tides due to pressure from six meters of water from below. That deformation does not take into account the glass window. Therefore, this has been analysed in FEM-Design and a fastening device has been dimensioned that holds the base plate in place.

The project lasted for five years. Throughout the process, from the first calculations until the underwater restaurant was completed and inaugurated in 2019, the engineers solved many difficult and advanced problems with the help of FEM-Design. It shows the power of the program and its wide applicability, both above and below sea level.

Article written by Love Janson