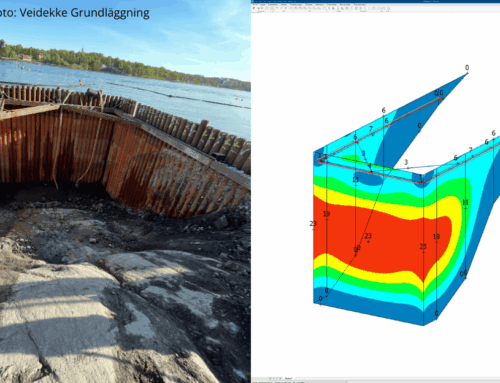

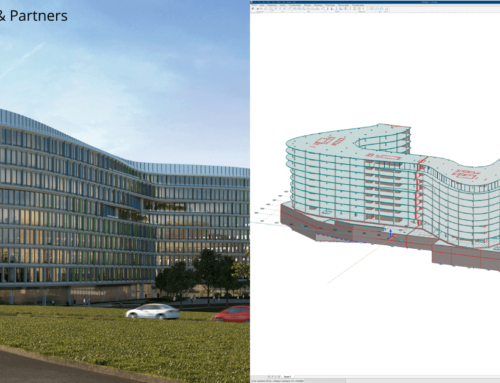

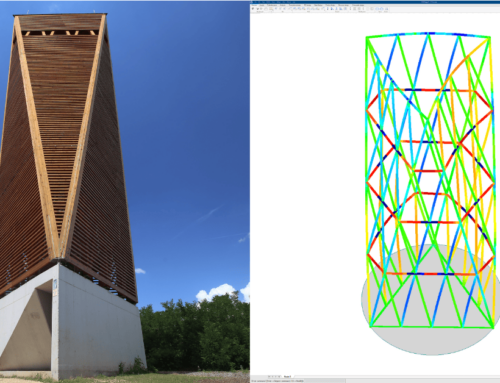

Våghuset is a new and beautiful building that is being built in Göteborg, Sweden. Its exciting design with wave-shaped glass façade and cantilever concrete slabs provided structural analysis challenges for Optima Engineering.

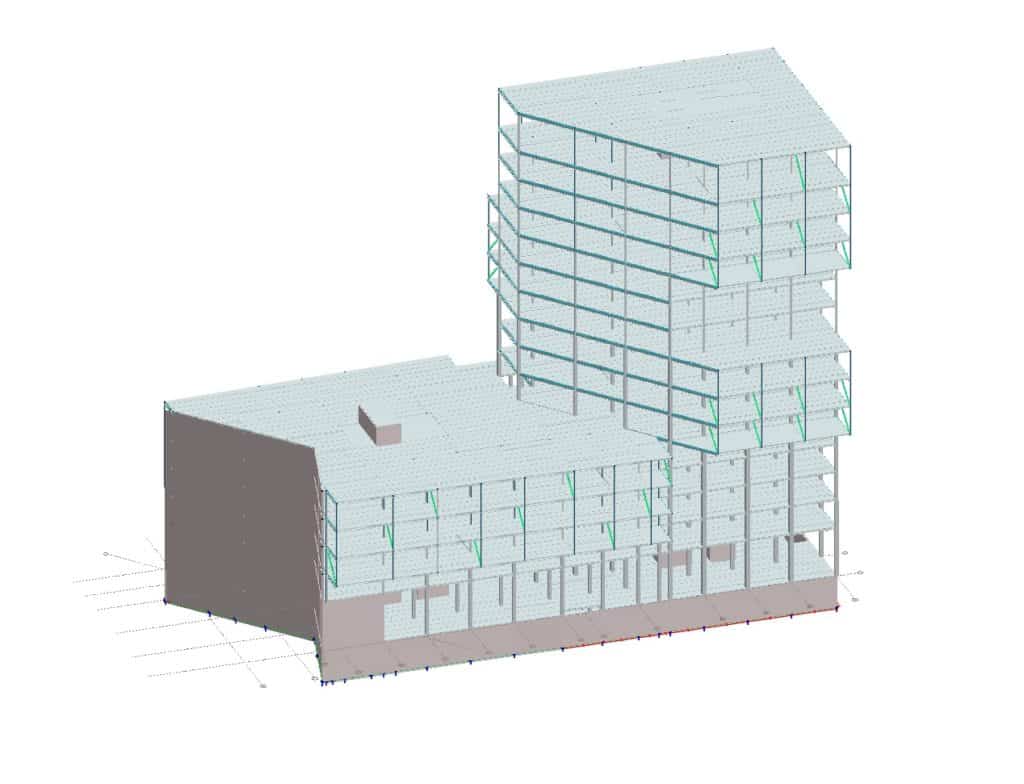

FEM-Design was used as an important tool for analysis to ensure the building stability, in all situations.

Right now, a spectacular building is being erected in the central part of Göteborg with a wavy façade. It takes its inspiration from Göta Älv, a river close by. This 13-story building will house mainly offices but also restaurants, cafés, and a gym. The developer is NCC Property Development.

The building consists of two high rise parts connected with a lower building. One of the high-rise parts is dressed with a wavy façade. The other is called Brick Studios consists of box-shaped volumes with cantilever parts in a playful composition. On the lower connecting part, a big roof terrace can be found.

The building complex will be finished in December this year and one of the tenants will be Optima Engineering, who are also responsible for the design of the structure. They played an important role in the project since they performed all stability calculations and were responsible for the load-bearing structure of the building. The structure consists of steel beams and columns with precast concrete hollow cores slabs. To aid the design work Optima Engineering used FEM-Design. The precast concrete manufacturer was Prefabsystem Syd.

Photo Credits: Optima Engineering

Structural analysis challenges were solved using FEM-Design

The two parts of the building have different structural designs and because of this, it introduced some structural analysis challenges to obtain stability for the whole structure. In addition to this, the wave-shaped façade creates alcoves on each level with beautiful views, perfect for a small meeting or a break. It forms a balcony and thus also the requirements corresponding to that type of structure. In this case, it was mainly focused on finding stability in this arch-shaped precast element, extending 3.5 meters from the supporting structure.

“It is important that we design with the correct curvature of the element since it is a central part of the looks of the building, at the same time you have to ensure the possibility to produce the element in the factory”, Mikael Furu explains.

Mikael is responsible for the analysis together with Jimmie Andersson and Jonas Persson.

“With the help of FEM-Design, we were able to model the element with the correct shape and supports”.

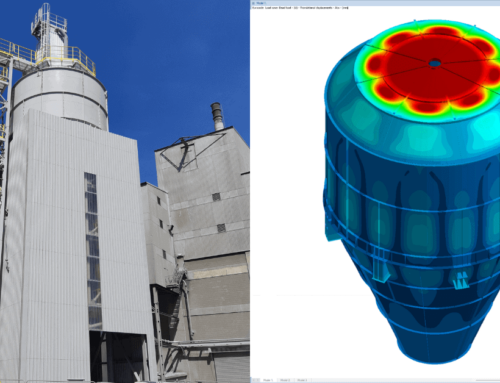

Another common challenge for high rise buildings is the large wind load. It is important that you design a stiff core in the building to prevent large deformations in windy situations.

“To prevent large deformations from the wind load, tension rods were cast into the foundation plate”, says Jimmie Andersson. They extend to level seven in the walls to pre-tension the structure for an increase in stiffness. We analysed how the forces were distributed in FEM-Design and performed design from the results.”

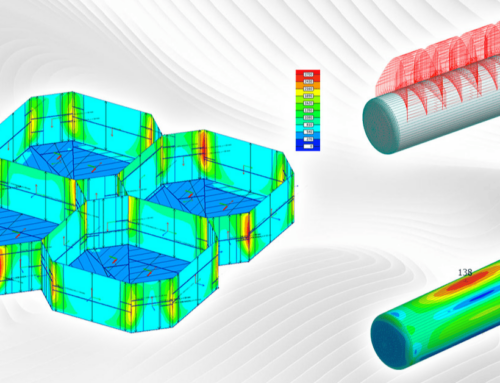

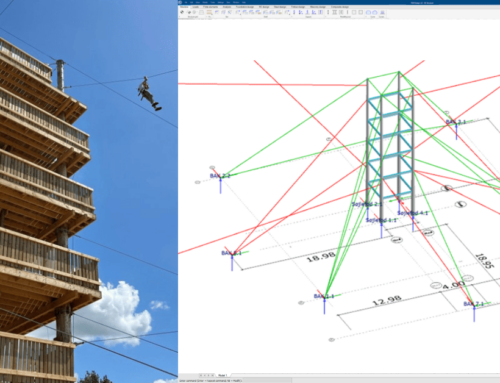

In one part of the structure, a large cantilever of five meters can be observed. To handle this, large trusses between the levels were introduced. FEM-Design was a good tool to calculate the horizontal shear forces obtained in the slab and the tension forces obtained in the trusses.

Analysis divided per level

Another challenge in the cantilever structure was that each level had different sizes and positions of the trusses. The truss system was distributed over multiple levels so that all tenants would be able to have an open floor plan.

“Because of the different level layouts, we were forced to perform a separate analysis for each level to determine shear and tension forces in the slab”, Jonas Persson explains.

The separate analysis for each level was combined with a global model for analysis of the whole structure where the overall stability was calculated. A better overview of the local effects was obtained and by dividing up the analysis this way, the calculation time was also improved.

In about six months it will be time for Optima Engineering to move into their beautiful new office, to which they contributed by providing the design and stability to this advanced project.

© Love Janson

Photo Credits: White Arkitekter