K-Prefab’s are a complete Precast Building Contractor, responsible for the entire process, supporting their customers all the way from design to final assembly. The implementation of a visual BIM Precast Production Planning software was a integral part of their continuous improvement.

K-Prefab build and develop sustainable multi-family homes, offices, public buildings, industrial and agricultural buildings. They are a nationwide player with locally produced precast elements in their production facilities around Sweden.

K-Prefab have been working with the IMPACT BIM Precast Production Planning software for the last 8 x years to provide control of their precast concrete projects throughout all their operations.

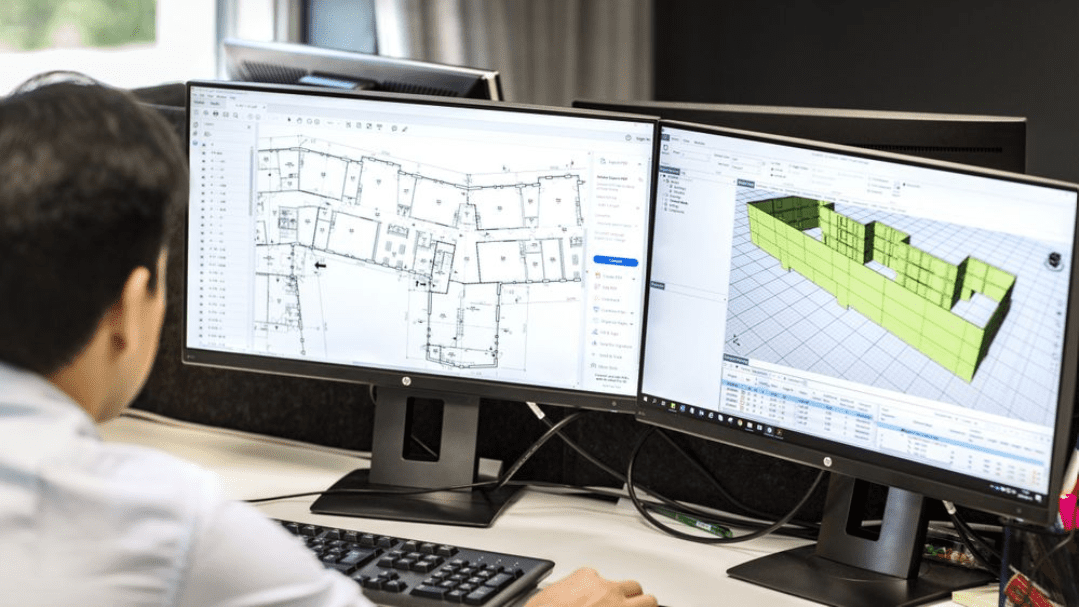

Integrated BIM Precast Production Planning

During their planning process, each precast project begins with the Construction Team setting the target times for the building assembly. Afterwards, planning backwards from the target date, the production and design can then be planned as efficiently and optimally as possible.

When they then get to the execution process, the different schedules are woven together in IMPACT, to allow the design, manufacturing and assembly to be optimised for performance.

“The digitisation of our working methods and the introduction of the IMPACT planning tool gives us project plans, controls, and deviation reports in the same program, results in large time savings. It also gives us structure and order it all our precast projects, both large and small.”, says Kaj Grönvall, CEO of K-Prefab.

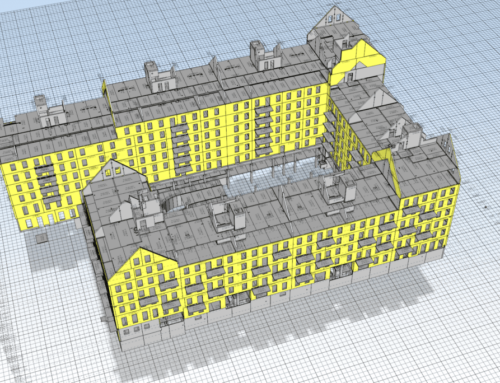

The quality increases when you eliminate manual input sources of error. The IMPACT system uses different colour codes for the elements in the 3D view; for every status through the process; to increase the visual overview.

Easily keep track of the entire Precast Project

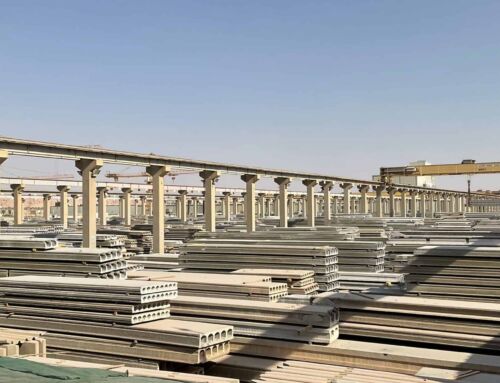

Through the colour codes, you can easily track which elements are ready in the stockyard, which are cast, and which are planned.

For transportation, this means that with the help of colours you can see which elements are to be loaded together. The integration with their transport company also provides benefits as load planning is streamlined in both the short and long term. During transport planning, transports are called from the system and delivery notes are generated automatically.

With IMPACT Go, the mobile application that comes with the tool, you now have the control records digitally instead of in paper form. Any issues or rejections are reported with the app and the Element Control. Each element produced has a unique QR code so that with the help of this and the app you can track the status of the element with detailed real-time information, get better controls and improve the processes.

You can read more about K-Prefab and their complete Precast Building Projects on their website by clicking here.

Book a Free IMPACT Demo

If you are curious to find out more about IMPACT and would like to find out more you can book a free demo by clicking here.