A new stormwater tunnel in Stockholm, Sweden, known as the New Östberga Tunnel (NÖT), required complex geotechnical solutions at its outlet into Saltsjön. Veidekke Grundläggning, a geotechnical contractor and sibling company to Veidekke Sweden, chose FEM-Design to engineer a robust, material-efficient retaining structure to support construction below sea level. The software’s powerful 3D modelling capabilities and intuitive design tools helped the team to optimise steel usage, improve design quality, and reduce the project’s environmental footprint.

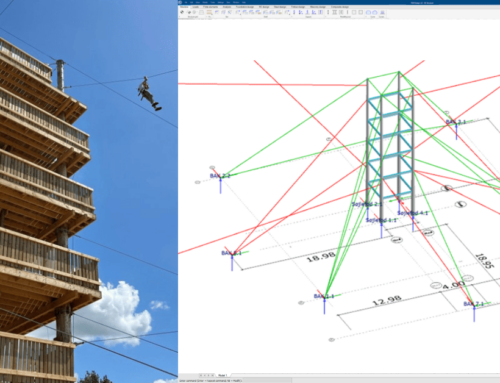

Project overview:

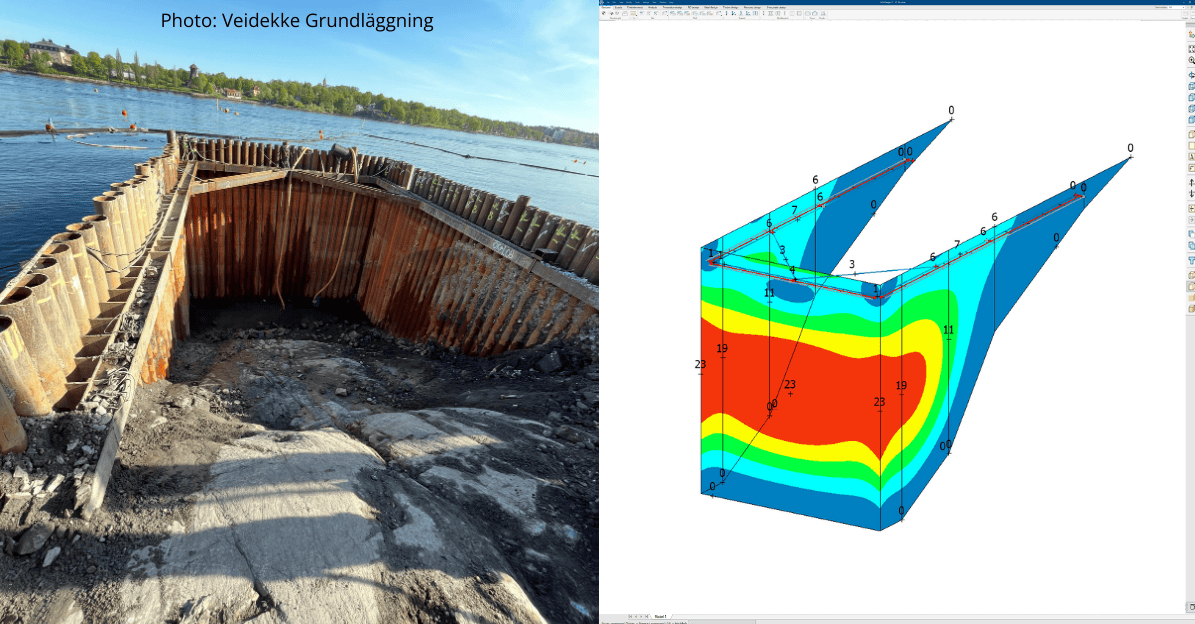

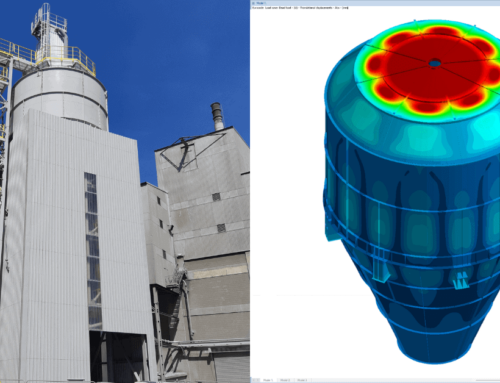

The New Östberga Tunnel was commissioned to separate stormwater from wastewater systems and reduce untreated discharges into Saltsjön during heavy rainfall events. A crucial part of the project involved constructing a 17×10 meter U-shaped retaining structure extending from land into the water. The structure needed to resist high hydrostatic and earth pressures while enabling safe excavation 10 meters below sea level for pipe installation along the seabed.

Geotechnical engineers Anders Palmen and Victor Granlund Hedén from Veidekke Grundläggning were responsible for the design. Their task was to deliver a robust and sustainable design solution for the tunnel’s outlet while ensuring cost-effectiveness and compliance with Eurocode.

“FEM-Design allowed us to step outside traditional geotechnical tools and use a more structural-engineering-oriented approach. It delivered both precision and efficiency,” said Anders Palmen, Geotechnical Engineer at Veidekke Grundläggning.

Engineering challenges:

The project presented several technical and design challenges:

- Underwater construction: The retaining wall must handle substantial water pressure in addition to soil and accidental loads.

- Accuracy in rock connection: Precise boundary conditions were critical for integrating the steel structure with the surrounding rock.

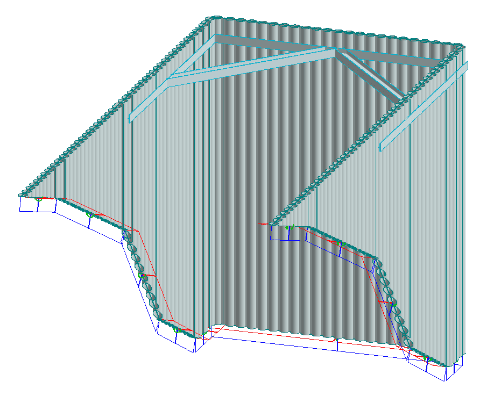

- Non-standard geometry: The support structure’s unique U-shape required a tool capable of efficiently modelling and analysing 3D effects.

- Learning curve: The team had to overcome the challenges of adopting a new calculation tool, moving beyond traditional 2D geotechnical analysis methods.

Why Veidekke Grundläggning chose FEM-Design for retaining wall design:

FEM-Design was selected for its ability to model and analyse complex 3D geometries with minimal effort. The software’s user-friendly interface and integrated steel calculation tools made it possible to analyse and optimise the retaining wall efficiently.

Key motivations included:

- 3D modelling of complex geometry

- Integrated design and analysis in one environment

- Easy section-by-section result interpretation

- Eurocode compliance

“We chose FEM-Design because it combines 3D modelling and steel calculations in one platform. That alone saved us a lot of time,” said Anders Palmen.

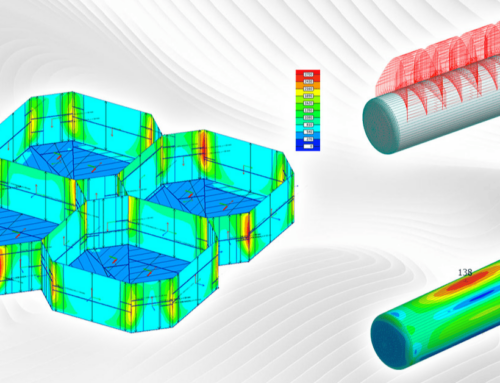

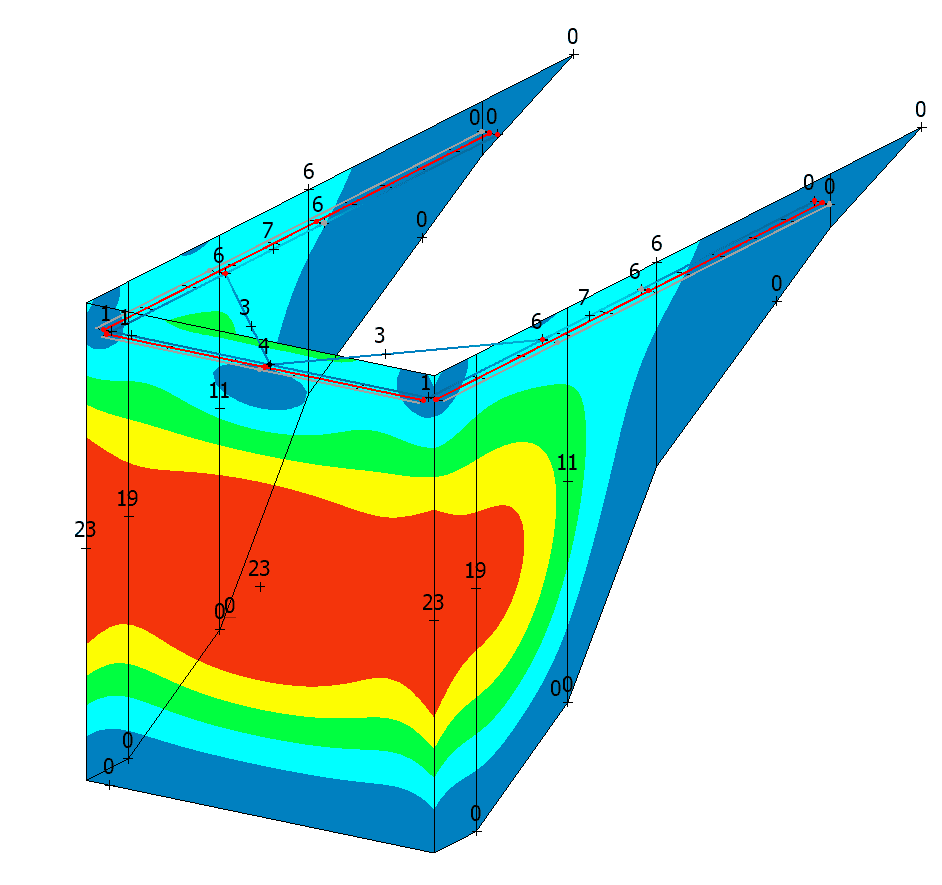

Figure 1: The calculated deflection of the wall elements in FEM-Design

FEM-Design’s impact on workflow:

Veidekke Grundläggning integrated FEM-Design directly into their design process, replacing traditional FEM tools and manual steel checks. The switch brought several benefits:

- Efficiency gains:

- With modelling and reinforcement design in the same tool, time was saved by avoiding separate workflows for FEM analysis and steel calculations

- Better material use:

- The team optimised steel usage and reduced welding needs thanks to accurate 3D results and visualisation of load paths, leading to lower costs and environmental impact.

- Higher accuracy:

- By simulating real boundary conditions in 3D, FEM-Design helped the team avoid over-conservative assumptions and achieve a more robust design.

- Short learning curve:

- Despite being new to the software, the intuitive interface enabled a quick learning curve for engineers from a geotechnical background.

“FEM-Design brought the precision of a bridge engineer’s toolkit into geotechnical design. It gave us better control and confidence in our results,” Anders added.

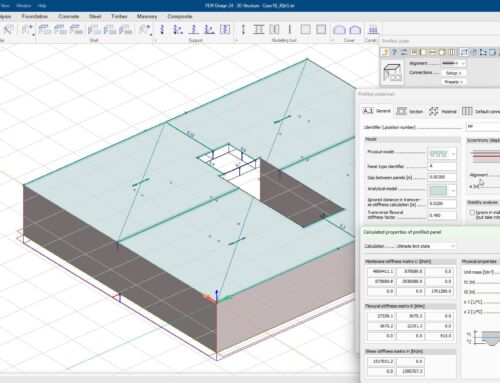

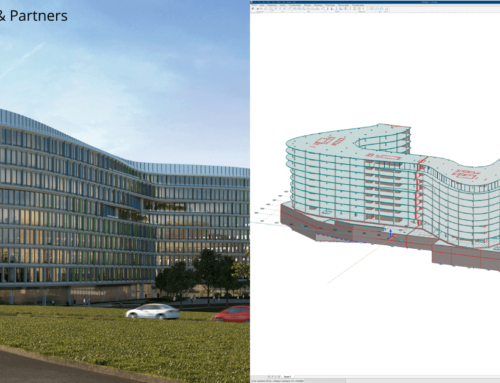

Figure 2: The shell elements and the boundary condition in FEM-Design

Veidekke Grundläggning has already used FEM-Design in several other projects and plans to continue doing so. Its versatility and time-saving capabilities make it a reliable tool for future geotechnical challenges, especially where optimisation and environmental impact matter.

Client testimonial’s about using FEM-Design for retaining wall design:

“Using FEM-Design saved us both design time and steel volume. This improved the project’s economy and reduced the environmental footprint. It’s a great tool, especially when working with relatively simple soil pressure that can be translated into triangular loads. For geotechnical engineers willing to learn something new, FEM-Design offers powerful possibilities,” Anders Palmen, Geotechnical Engineer, Veidekke Grundläggning.

Client portrait:

Veidekke Grundläggning is a geotechnical engineering company and part of the Veidekke Group, one of Norway’s largest contractors. Founded in 1936, Veidekke works across housing, commercial, industrial, and infrastructure sectors in the Nordic region. Veidekke Grundläggning focuses on the design of geo-constructions such as retaining walls, pile foundations, and temporary structures during construction phases.