The Dome installation at the ARoS Art Museum in Aarhus, Denmark, required intricate engineering solutions. Mads Suikkanen, a structural engineer at COWI, was tasked with calculating the concrete structure of the dome and used FEM-Design for geometric modelling, to obtain accurate load calculations and determine precisely the areas where reinforcement could be optimised.

Project overview:

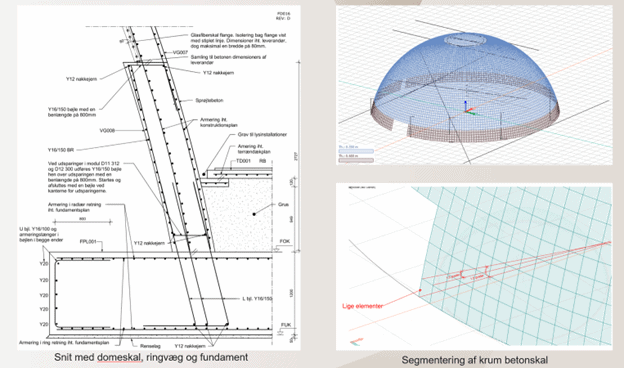

The structure measures 16 meters in height, with a diameter of 40 meters at the base and extends 8 meters below ground level. The Dome’s interior consists of fiberglass as part of the art installation, while the outer structure is made of reinforced concrete designed to support the surrounding soil.

The Dome is built with a circular strip foundation at the base, 1.2 meters deep and between 4 to 4.6 meters wide, cast integrally with the concrete walls of the structure.

The project’s expected completion date is 2025.

Engineering challenges

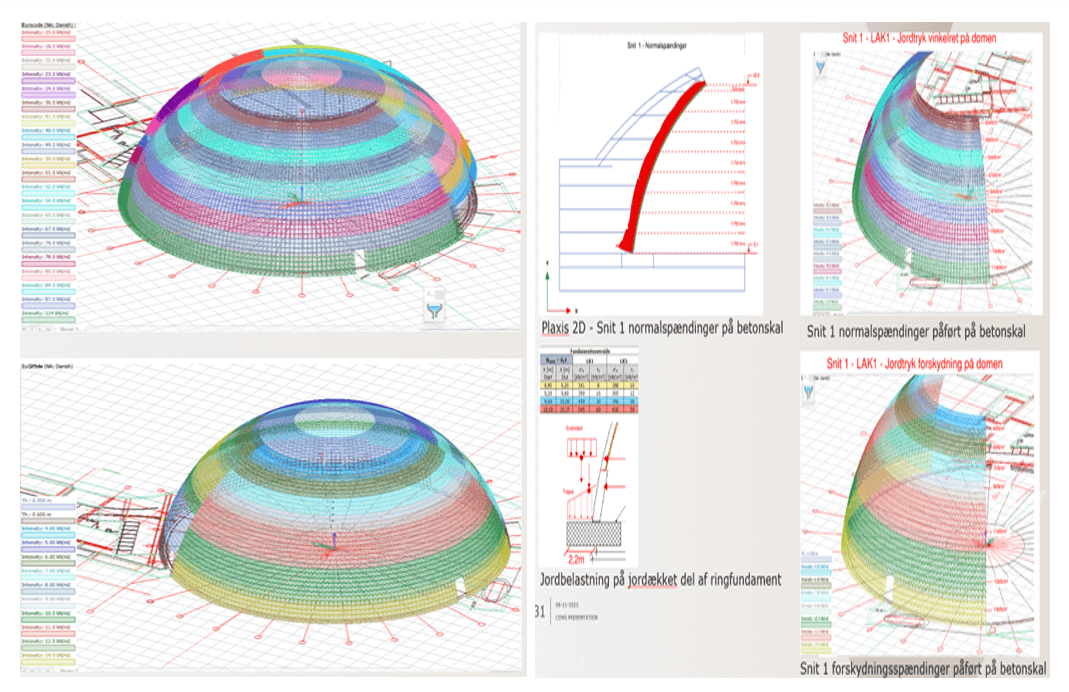

The project team faced multiple challenges during the design phase of the Dome, particularly related to loading conditions. The structure was subject to varying loads due to different types of soil fillings and its connection to an underground hallway that links the existing museum to the Dome. Additionally, the Dome featured a light steel structure on top, supporting a movable lid that can cover the Dome. The lid, operated on rails, can be concealed within the steel structure, which also houses a machine room for maintenance.

The complexity of these interactions required close collaboration with other specialists, including geotechnical engineers for soil loading and suppliers for steel structure and lid load calculations.

FEM-Design’s role

Mads Suikkanen conducted a study at the start of the project to determine the most suitable software for static calculations. He preferred FEM-Design due to its user-friendly interface and ability to provide results that closely matched those obtained via hand calculations for simple loads.

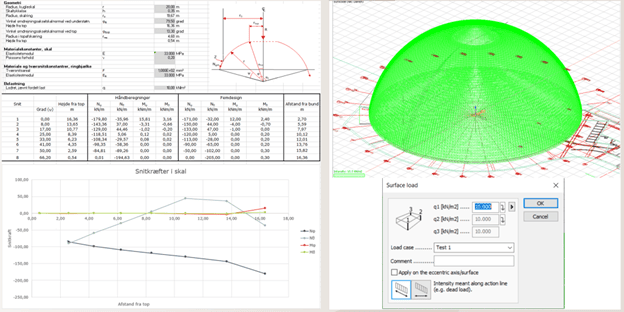

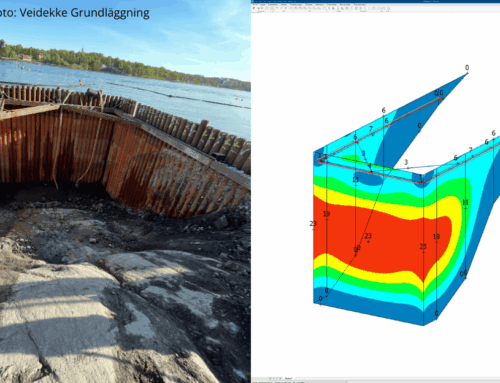

Figure 1 – Comparing results in FEM-Design with hand calculations. Copyright: COWI A/S

The software also allowed seamless integration with existing workflows by enabling the import of 2D construction plans and exporting results for further use.

“I was responsible for the static calculations of the reinforced concrete for the dome. It was the foundation, reinforced concrete shell and connecting concrete walls and slabs to the dome,” says Mads Suikkanen.

Key features of FEM-Design that proved invaluable to the project included:

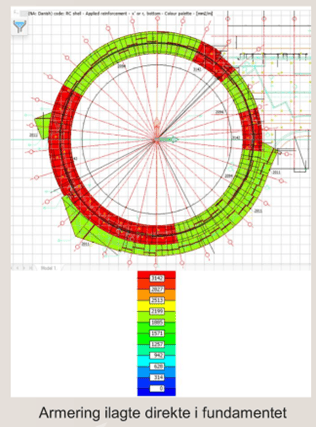

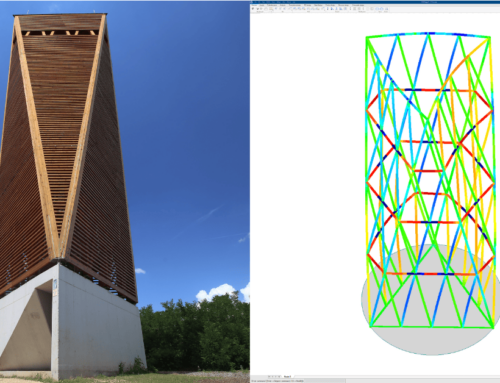

- Reinforcement optimisation: FEM-Design enabled precise determination of areas where reinforcement could be optimised, particularly at the top of the Dome, where spacing and casting concrete posed challenges.

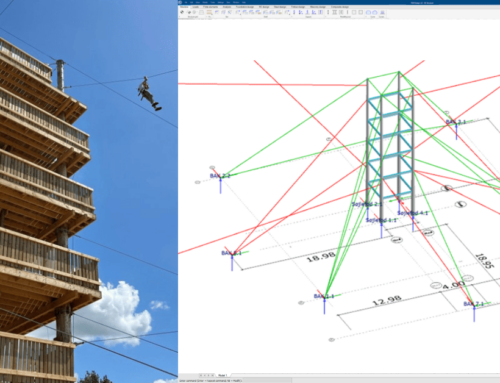

- Geometrical modelling: Functions like polar copy and line division allowed the engineers to create a fine mesh of segments to model the Dome’s curvature accurately.

Figure 2 – Geometrical modelling in FEM-Design. Copyright: COWI A/S

- Importing plans: The ability to import detailed construction plans was essential for applying complex loads around the Dome.

- Loading tools: Features such as “Labels” and the result tab for shells helped visualize and analyse the loading distribution on the dome.

Figure 3 – Loading on the dome. Copyright: COWI A/S

The workflow began by creating a FEM-Design model of the Dome based on 2D construction drawings. Once the structural analysis was completed, the reinforcement design was produced in 2D, and the contractor then modelled the entire structure in 3D for execution.

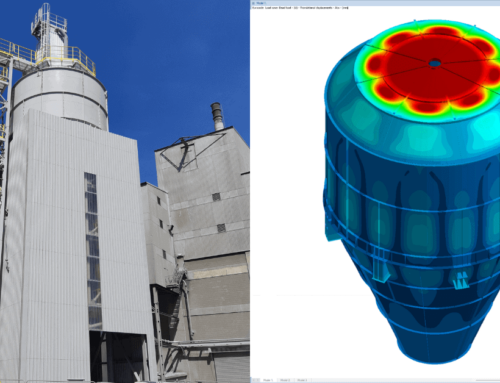

FEM-Design’s fast analysis capabilities allowed the engineers to identify areas where reinforcement could be minimised or enhanced to optimise structural performance. The reinforcement in the foundation was also optimised by using FEM-Design. They marked the areas around the dome to see how much reinforcement was needed in different directions.

Figure 4 – Optimising reinforcement in ring foundation around the dome. Copyright: COWI A/S

“The FEM-Design model ran the structural analysis quickly, and it was possible to determine areas where the reinforcement could be optimised. It was necessary to optimise the reinforcement since the reinforcement layout was done by single rebars, and the spacing was critical at the top of the dome due to the ability to cast the concrete,” adds Mads Suikkanen.

In conclusion, FEM-Design helped the engineers to produce accurate and reliable static calculations, optimise the reinforcement layout, and integrate smoothly with other design tools. Looking ahead, FEM-Design remains a top choice for Mads Suikkanen when calculating complex concrete structures.

“I’m very happy to use it on complicated reinforced structures. It gives results that I find afterwards that can be approximated by hand calculations, which makes it a trustworthy software. I had a lot of fun using FEM-Design for the reinforced concrete dome in this project, and I feel confident about using the program for other complex concrete structures,” concludes Mads Suikkanen.

Customer portrait:

Mads Suikkanen has been a structural engineer at COWI’s Aarhus office for over five years. His expertise spans global projects involving various structures, focusing on reinforced concrete and structural steel. He first discovered FEM-Design during his studies at Aarhus University.

COWI A/S is an international consulting group headquartered in Lyngby, Denmark. The company delivers expertise in complex projects involving infrastructure, construction, and environmental solutions, supporting sustainable and innovative developments worldwide.

Optimising concrete reinforcement is fast and complete with FEM-Design

Whether working in a full 3D modelling environment or reviewing elements individually in 2D, FEM-Design can help you streamline the process of optimising concrete reinforcement from start to finish. It can deliver a robust and reliable design in a short amount of time.

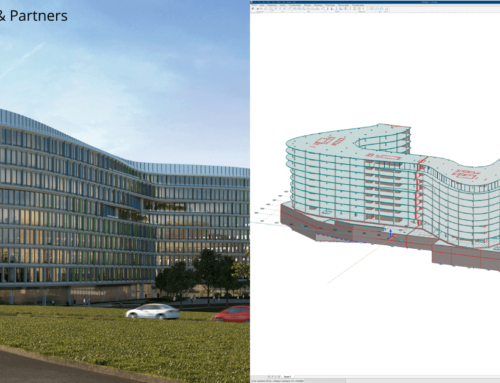

Take a look at two other recent examples of our software being essential in optimising concrete reinforcement: Jätkän Kruunu in Finland and Slagsta Strand Kv – 7 in Poland.