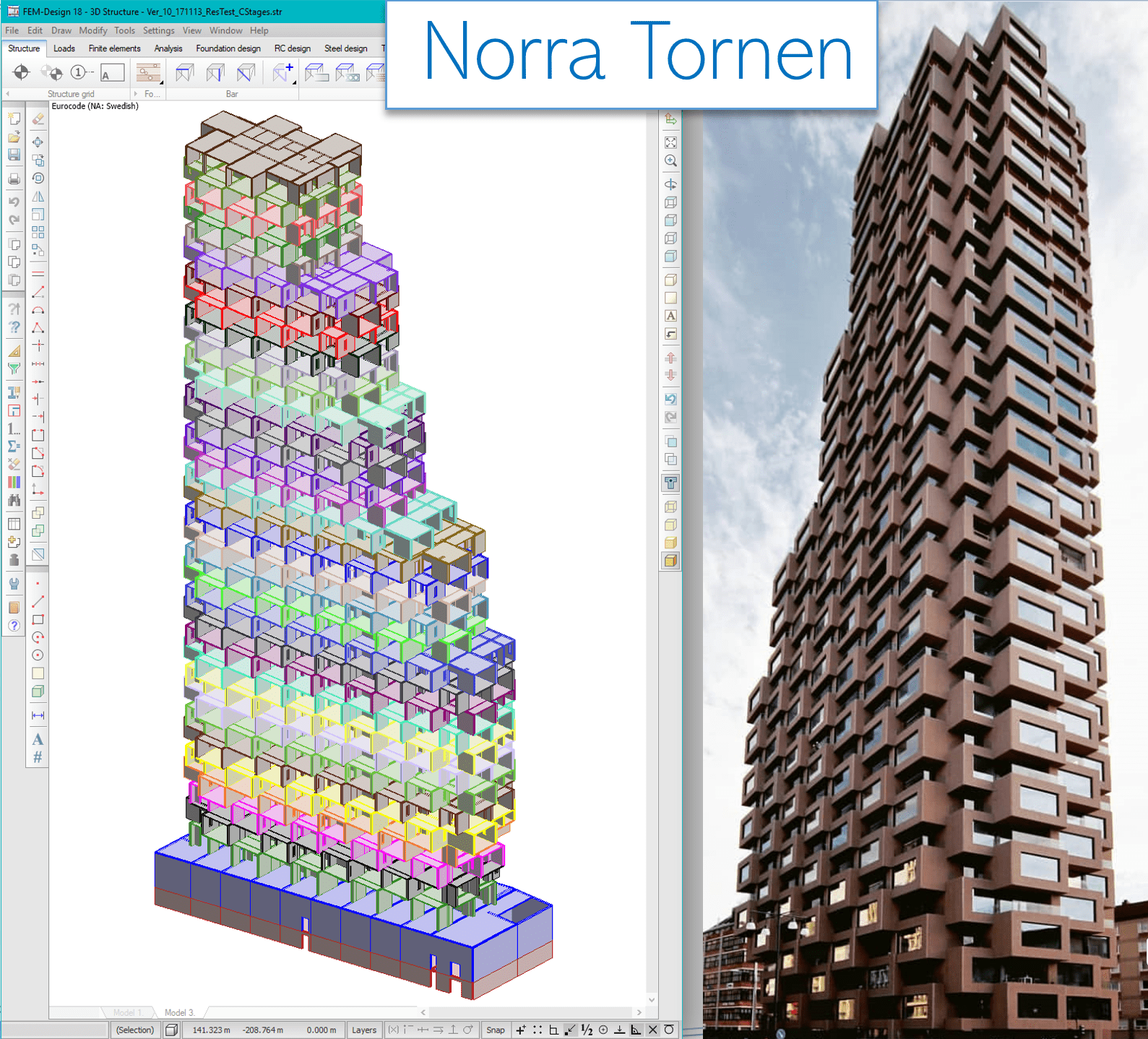

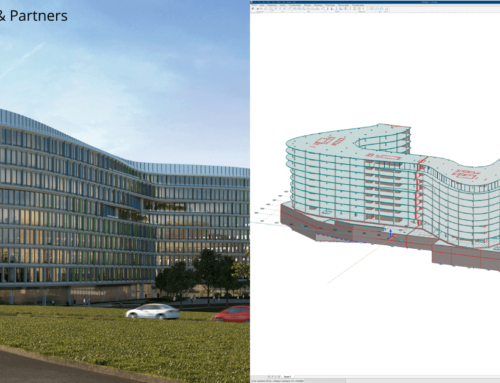

An exclusive residential building project has been completed in the Vasastaden district of Stockholm, Sweden. Norra Tornen has been developed by Oscar Properties, with the Innovation Tower set to be the tallest residential building in the city, at 125 meters (410 feet) and 38 floors. The second, Helix-Tower, is just a bit smaller at 36 floors. Both towers have a unique design, in the form of box-shaped modules that have been merged together that required advanced structural load analysis.

Separate structural design for every floor

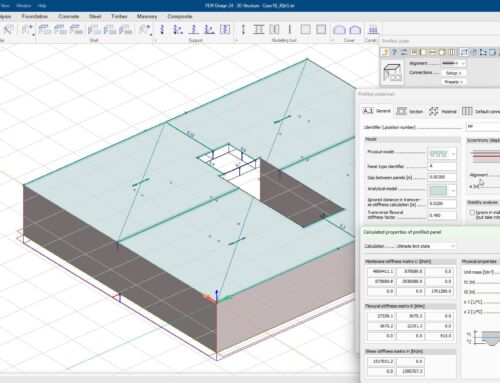

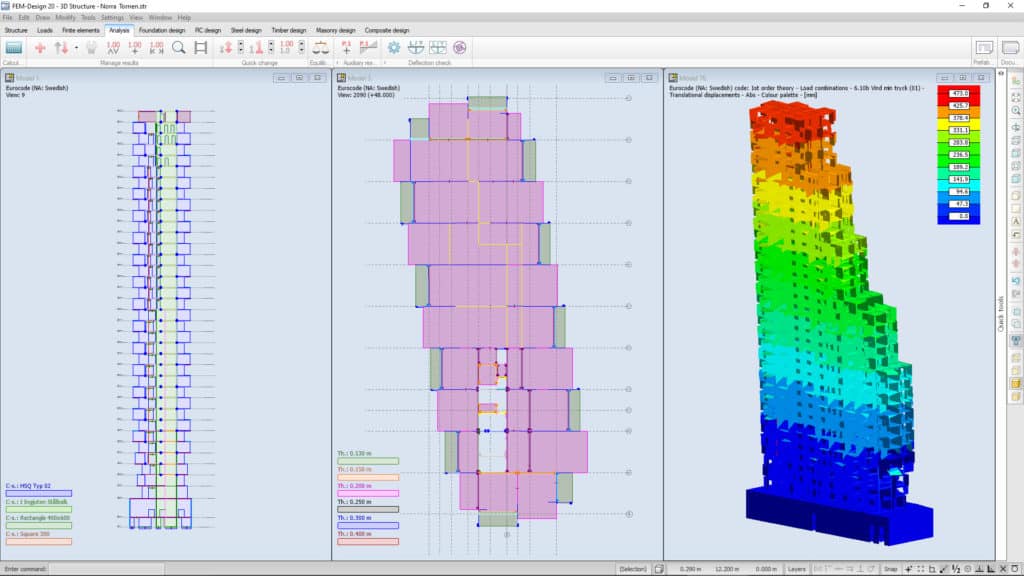

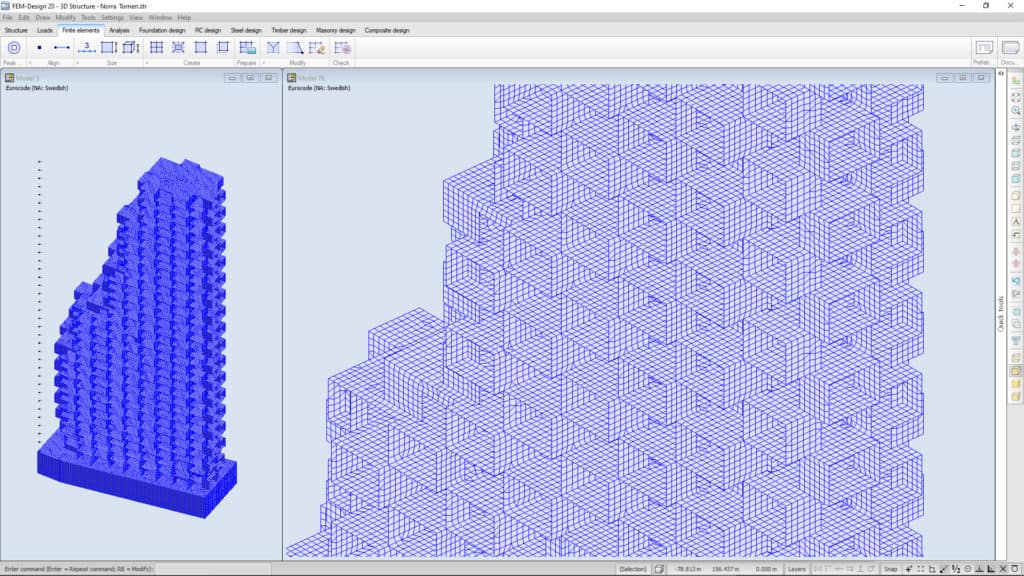

Advanced design work was required on such a structure. Sweco Structures, consultants for the project, carried out an extensive analysis of load distribution, both at a local and global level. To achieve these calculations, they used FEM-Design.

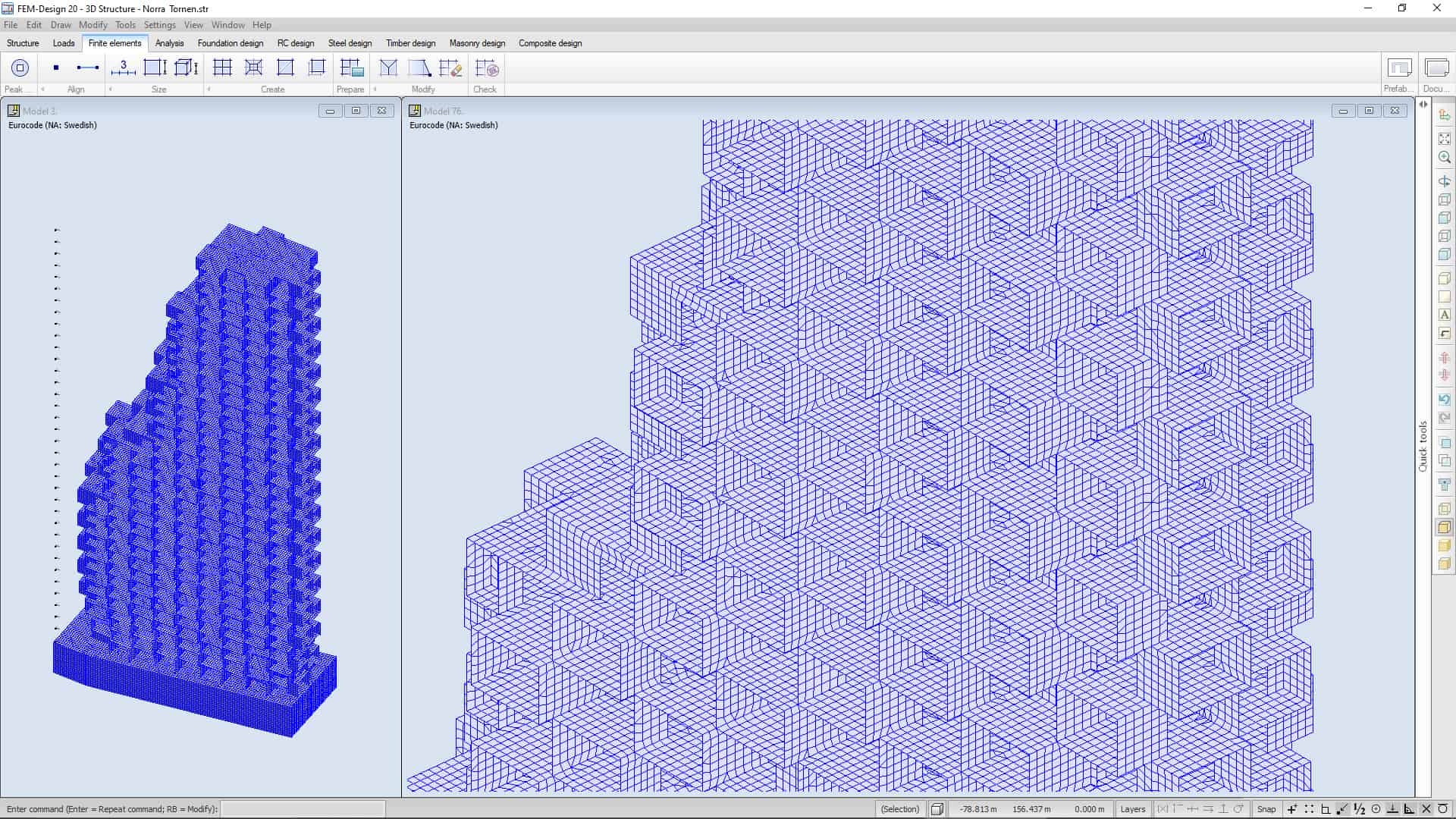

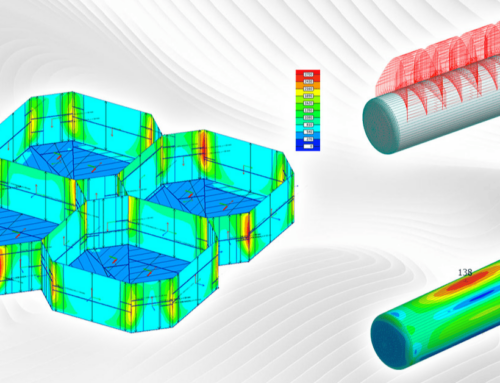

“We have calculated the loads in and between every prefabricated concrete element to design them”, says Marco Binfaré from Sweco. “There is not a lot of software able to do that.” Firstly, Sweco built the entire FEM-model to see how the building turned out. Afterward, every element was designed and coupling forces analysed.

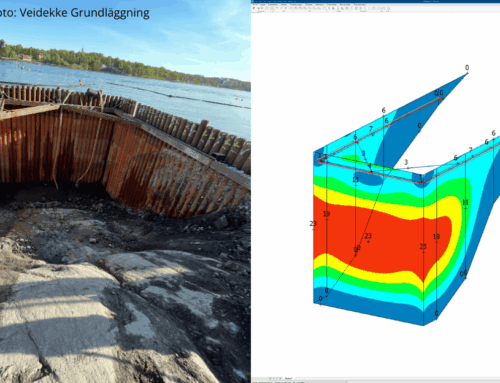

Marco and his colleagues found the software especially useful in calculating elements with complex geometry. They were able to simultaneously continue analysis at the global level using the 3D model to see how forces were distributed in walls and down to foundation level.

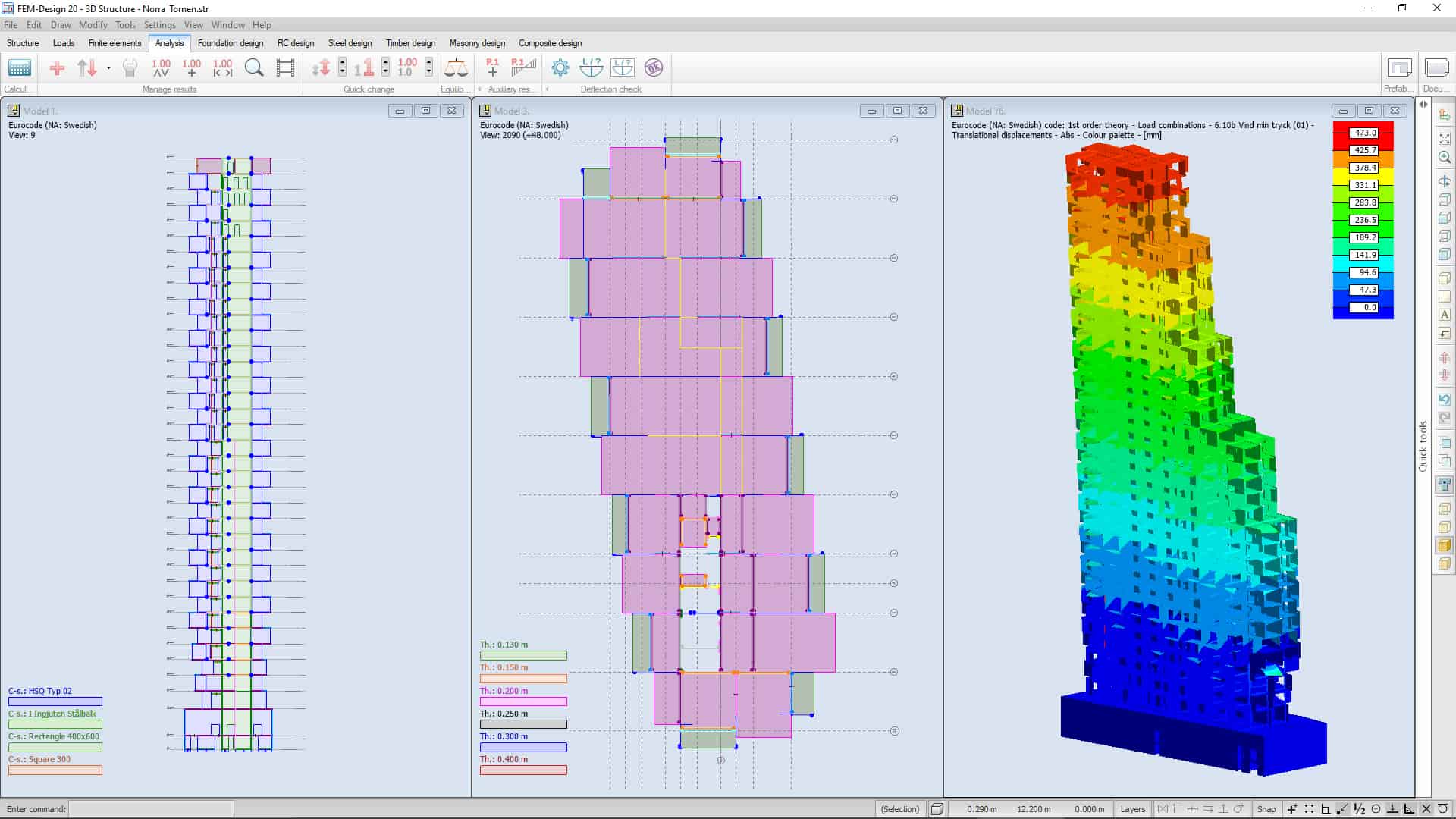

They worked in both levels and elevations in order to account for individual elements and the entire construction – imperative due to the complexity of the structure. Another important area was in analysing the effect of external forces, such as wind. A key focus was put into a wind-induced acceleration in the upper floors.

“We analysed the dynamics in FEM-Design by calculating the natural frequency of the building, and after that, we calculated acceleration on the upper floors. FEM-Design enabled us to understand the structural behaviour and design the building to fulfil requirements.”

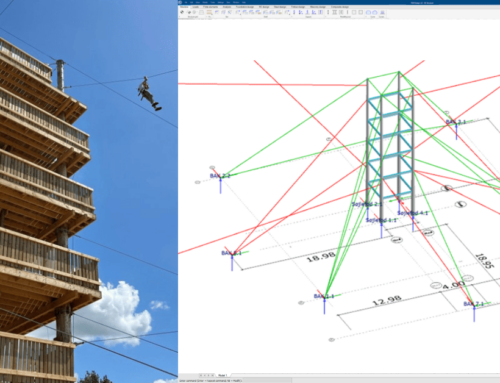

3D framework essential for advanced analysis

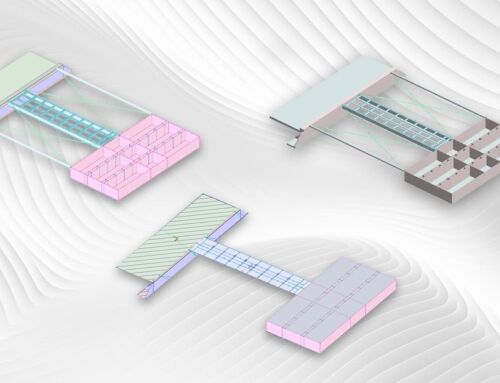

Sweco carried out multiple local analyses for the project. The distinctive design of the building puts high demands on the structure’s ability to resist loads. With the tower extending in various directions and aspects, large forces must be moved laterally, in turn creating significant tension loads. Marco continues:

“In order to analyse these forces, we built three frame girders in 3D, as a separate model based on the global one. We simulated forces and ascertained the design basis for clamping cables that hold the construction in place. These cables are anchored in the core of the building using reinforcement.”

Local analyses were also carried out on stabilising walls with door openings and holes for pipes in the door cover, which don’t have the same stiffness as a complete rectangular wall.

This was compensated for by adding steel beams to the top of the openings. To get the design right on the beams, Marco and his colleagues created separate models in the program for each steel beam, modelled individually with details of holes made for installation.

Automated workflow to export structural model data to Excel

Due to its size, the Norra Tornen project generated huge amounts of data. Sweco Structures needed to manage this information internally, and therefore wanted an automated download of load data from the model. They were able to collaborate with StruSoft to export this data to Excel, and this automated workflow saved considerable time.

“It saves a lot of time”, Marco points out. “Manual input errors are eliminated, and this helps ensure the required prefabricated concrete elements are of high quality.”

Norra Tornen is yet another ambitious and distinctive project which has been made possible with FEM-Design.

Interview by Love Janson, ComWise AB