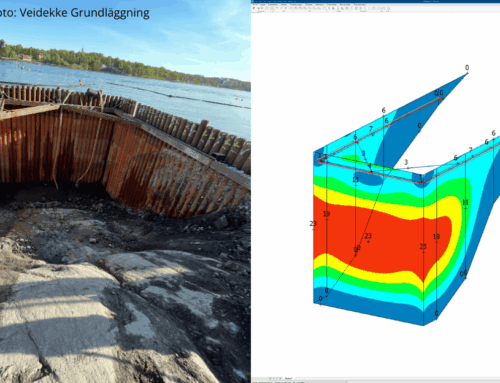

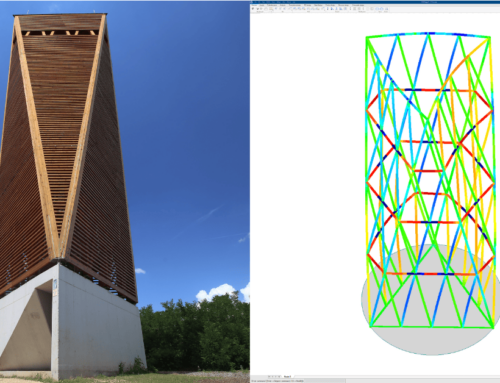

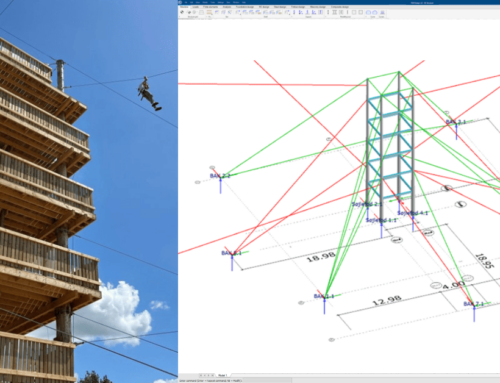

Stockholm is the fastest growing city in Europe, with 90% of goods being transported by sea into the city. South of Stockholm, a new port – Norvik, is under development to replace Frihamnen and to handle and store goods. Consulting Engineering Firm, Ramboll, were tasked with a challenging 3D steel structural design.

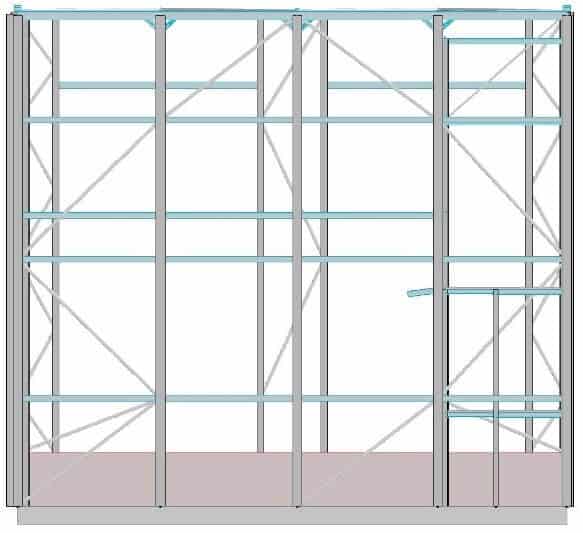

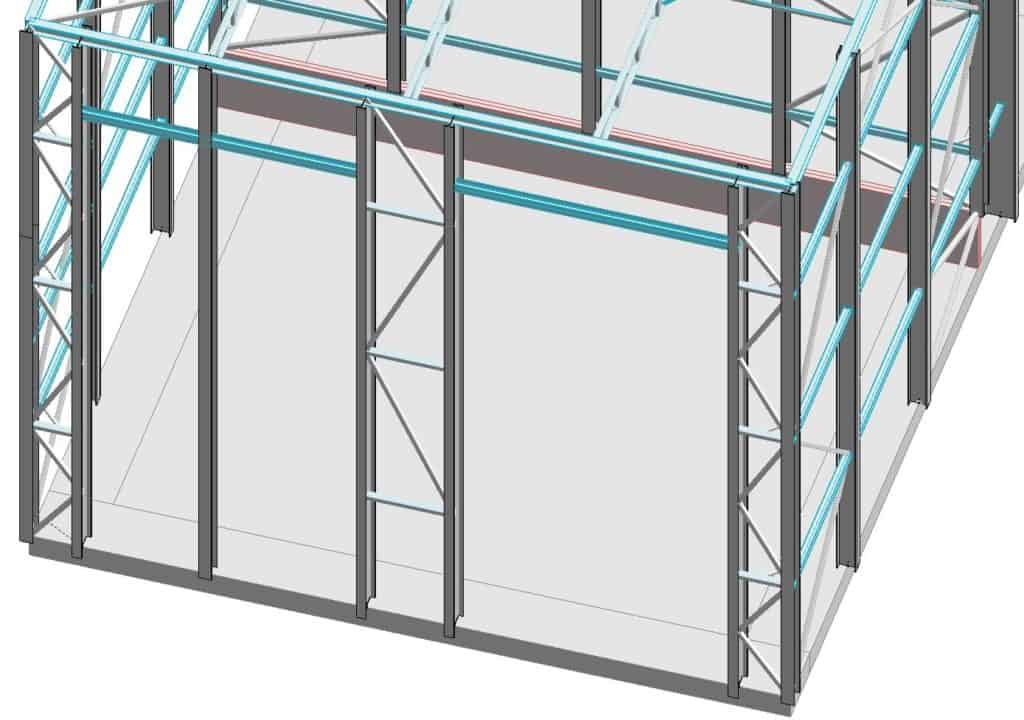

The task in hand was a 24m high warehouse to house shipping containers and would allow for future expansions of the steel structure. One of the main challenges was the ineffective height to span ratio, making lateral forces (i.e. wind load) a decisive factor when choosing the load-bearing system. Situated on the coast, the initial calculation resulted in a 1100mm deflection.

Wind load

The wind load was generated automatically using the Wind macro tool, which also created several wind-load cases according to the terrain type and building height. The cover function distributes the surfaces’ wind load to the supporting steel structure and can handle surface, line, and point loads.

Sway/non-sway frame

Due to large sway, a sensitivity analysis was performed to study boundary conditions and their effect on the structure behaviour. With scripting API, it is possible to run multiple calculations automatically and explore different solutions in FEM-Design.

The class 4 welded sections have been hinged at the ends to take into account the worst-case scenario and consider the maximum sway possible. A different challenge came from large joint forces and deformations at corners due to the ineffective height of the roof truss, which also needs to take the loading from the solar panels.

A hinged connection was set between the column and the foundation. FEM-Design allows for the analysis of the interaction between foundations and supra-structure.

Steel Joints

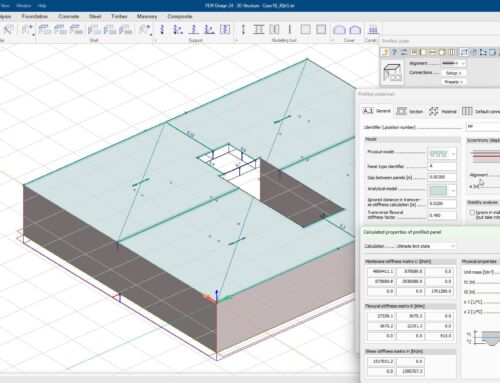

Having a sway frame in one direction and a non-sway frame in the other direction results in having semi-rigid connections. The Steel Joint Module can calculate the rotational stiffness of joints according to Eurocode and the 3D model of the steel structure can be analysed using semi-rigid joints.

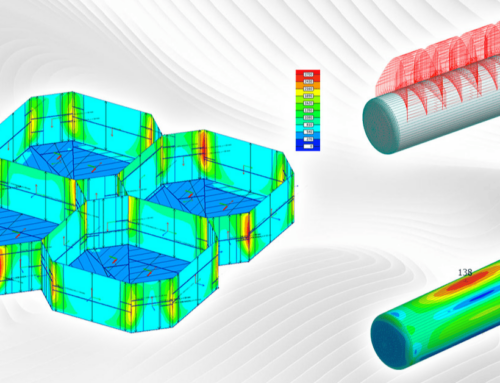

Steel design/buckling

When it comes to steel design, buckling verifications are essential. The Steel Design Module allows for automatic calculation and assigns of buckling length for flexural buckling (in stiff and weak direction) and lateral-torsional buckling.

Plastic limits for foundation

In order to avoid uplift, the foundation stiffness was limited in tension. It is very easy to set up plastic limits in FEM-Design supports and perform a plastic calculation to obtain convergence. All the forces that went above the plastic limit were distributed to the rest of the supports.

If you are interested to find out more about this project you can watch a webinar recording below by Siavash Ehsanzamir of StruSoft. Siavash was the actual structural engineer who designed the project when previously working for Ramboll.