A pioneering aquaculture infrastructure project in northern Sweden required innovative structural solutions to support a retaining wall and pontoon-bridge system in a freshwater lake environment. UNDEKO, a civil and environmental engineering consultancy based in Gothenburg, turned to FEM-Design to tackle this complex task. By leveraging the software’s dynamic analysis features and intuitive modelling tools, UNDEKO engineered a robust, adaptive structure capable of withstanding seasonal water level fluctuations, wave forces, and mooring loads.

Project overview:

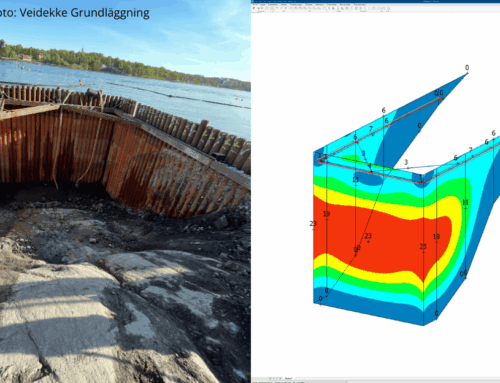

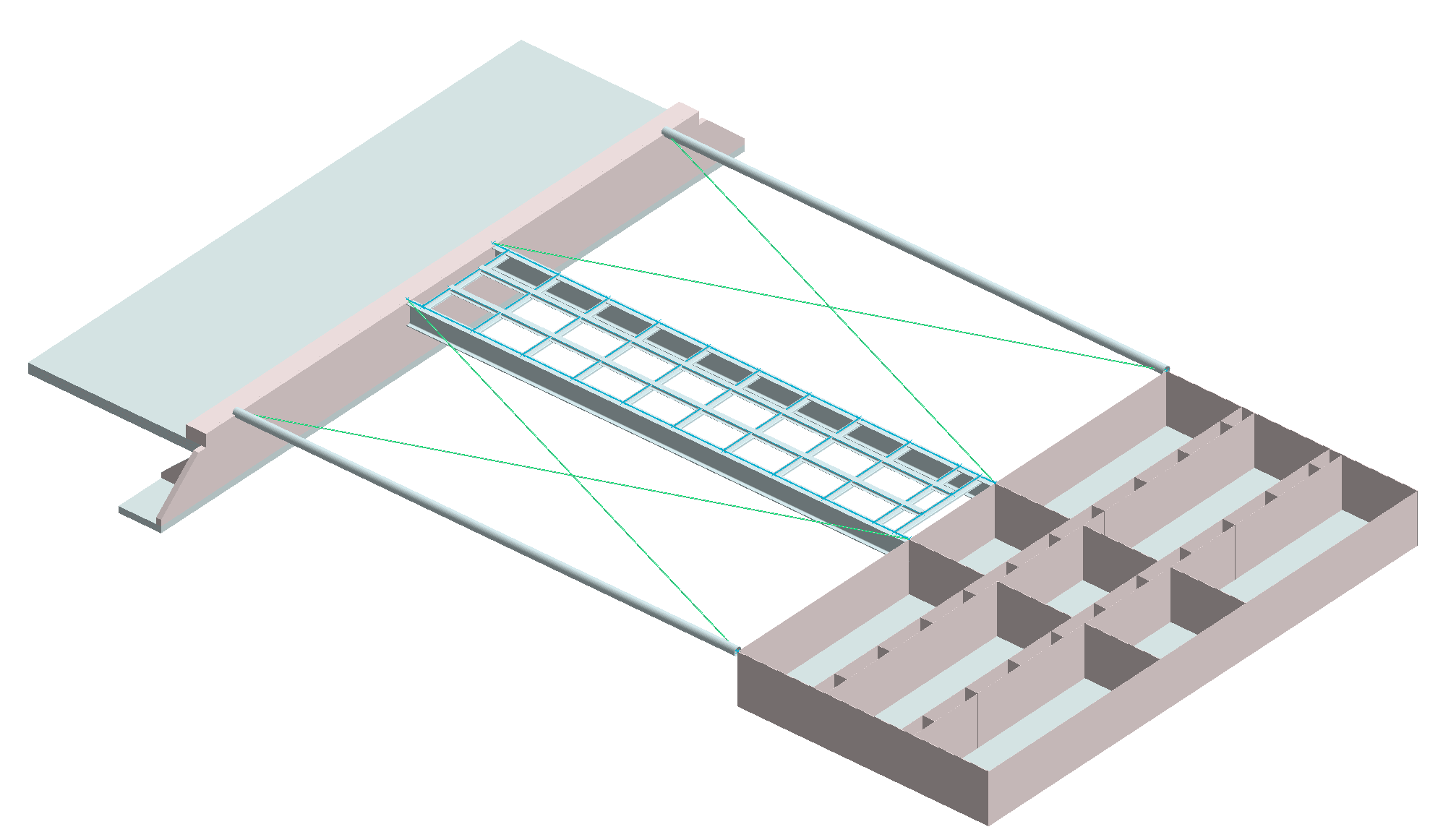

The project is part of a new fish processing facility in northern Sweden, designed to connect offshore fish cages to the mainland via a floating pontoon and a 20-meter bridge. This system is anchored to a concrete retaining wall that supports a 70-meter pier, enabling year-round access and functionality despite extreme environmental conditions.

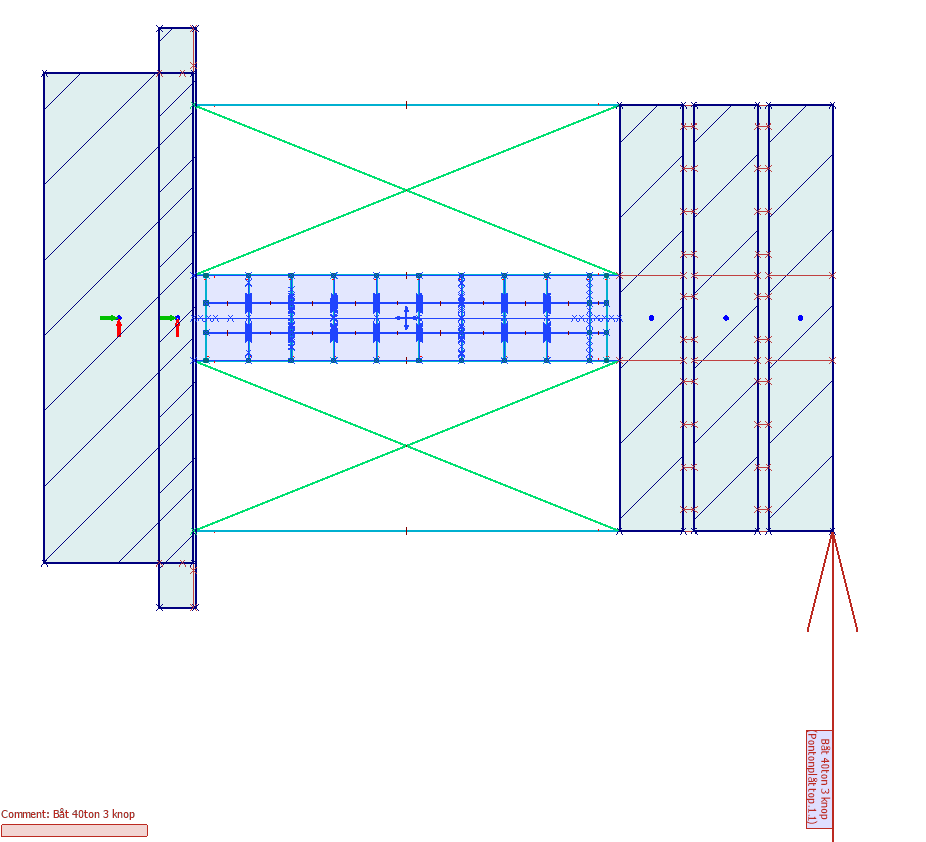

Designed in 2024, with casting completed during the summer, the system is set to become operational in 2027. The retaining wall had to account for heavy traffic loads, impulsive impacts from docking vessels, and vertical/horizontal wave-induced oscillations.

Engineering challenges:

The team encountered a unique set of engineering challenges:

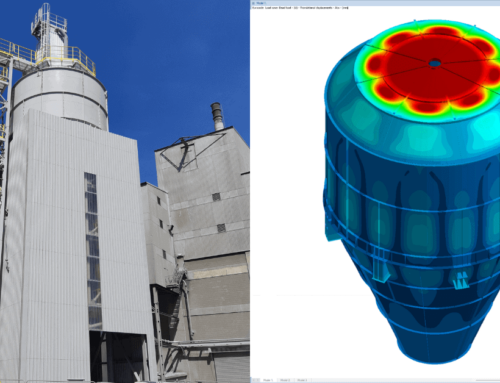

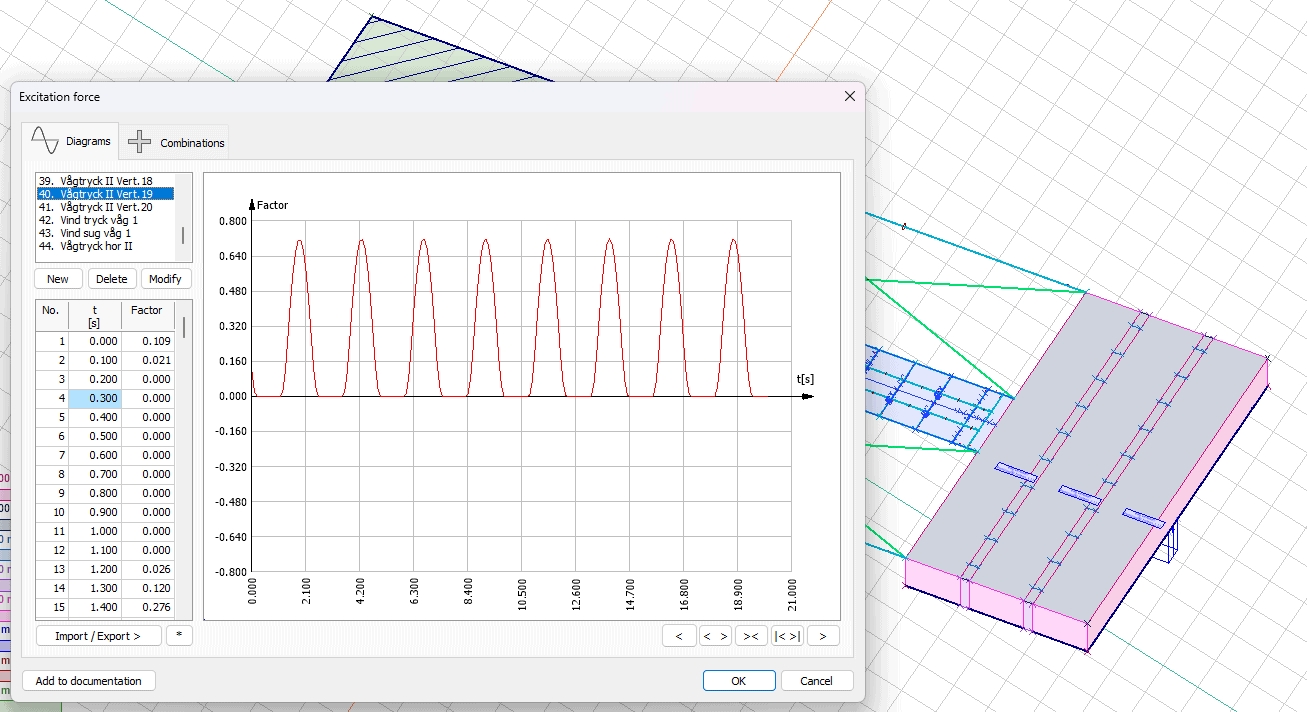

- Wave-structure interaction: The pontoon system responds dynamically to wave action, modeled as a forced-damped harmonic oscillator.

- Resonance avoidance: Eigenfrequency tuning was essential to shift the structure’s natural frequencies away from the dominant wave frequencies.

- Seasonal variability: The dramatic 7-meter shift in water level required calculations for multiple operational scenarios.

- Complex dynamic loading: Time-history analysis was needed to simulate the impulsive and rhythmic loads caused by wind and waves.

Why UNDEKO chose FEM-Design:

Lorenzo Guastalli, structural engineer at UNDEKO, led the modelling and analysis efforts:

“FEM-Design is our go-to software for modelling complex load patterns and dynamic combinations. It gives us the right balance between flexibility and structured design tools for a wide range of structures—from bridges to buildings,” said Lorenzo.

The key reasons for selecting FEM-Design were the following:

- Dynamic load modelling using user-defined time-history curves

- Flexibility in material and load type definitions

- Intuitive workflow and seamless DWG import

- Integrated design and documentation environment

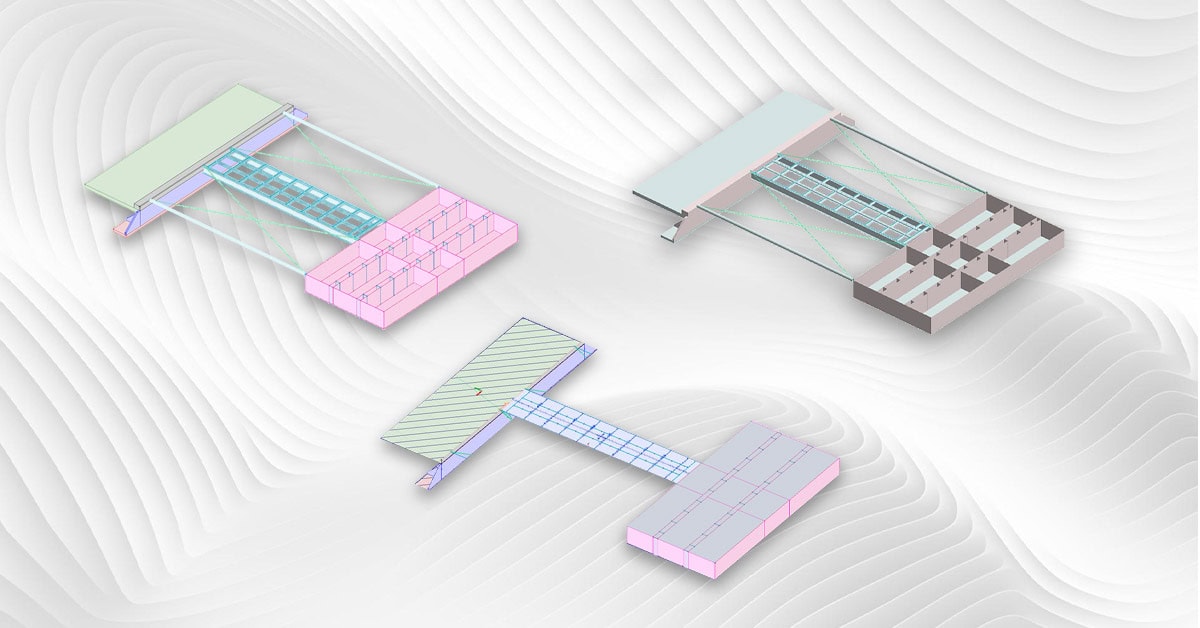

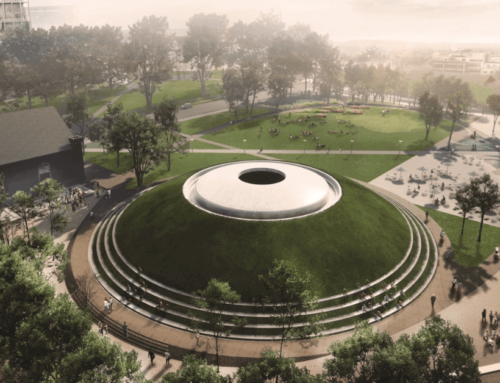

Ground plate and retaining wall stabilise the pier

Key features utilised:

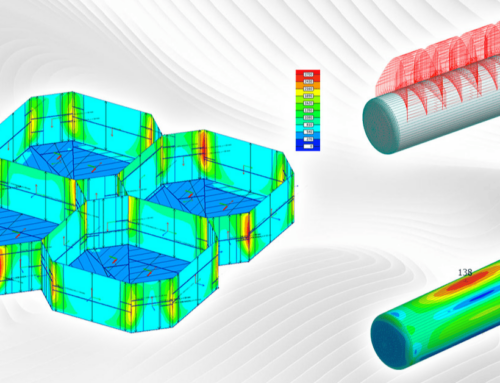

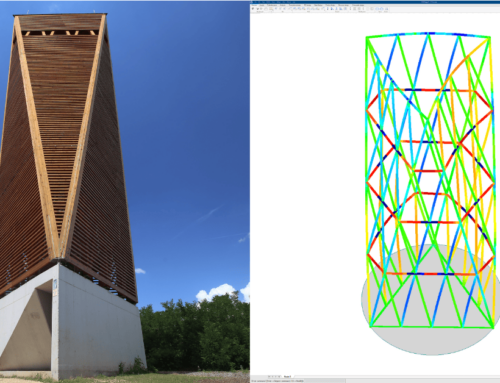

A standout element in this project was FEM-Design’s time-history analysis capabilities. Drawing from his background in seismic engineering, Lorenzo adapted wave forces into a series of time-stepped loads:

“I hadn’t done this type of calculation before, but I treated the wave crests as discrete pulsating loads and defined a custom time history for them. It worked perfectly,” Lorenzo explained.

Time-history analysis in FEM-Design

Other functionalities were used:

- Accurate 3D representation of the structural system

- Support motion modelling to simulate the geometrical shift due to water level changes

- Load scenario definition under varying environmental conditions

- Automatic generation of reinforcement and concrete detailing

- Export-ready output for executive construction drawings

Workflow integration and benefits:

UNDEKO integrated FEM-Design throughout their design pipeline, from early concept modelling to final documentation. The team gained the following:

- Time savings: DWG imports allowed rapid model generation, while combined analysis and design reduced workflow steps.

- Design precision: FEM-Design enabled a detailed understanding of 3D load distribution, especially under dynamic loading, leading to more efficient concrete and reinforcement dimensions.

- Cost-effectiveness: The design avoided over-dimensioning, reducing material use and construction costs.

- Knowledge transfer: Dynamic analysis was implemented without needing external plugins, helping UNDEKO develop internal capability for future wave-affected projects.

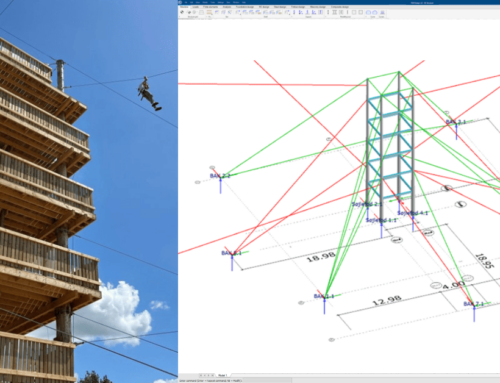

Accidental load given by a boat which weighs 40000 kg and collides at a speed of 3 knots

Client testimonial:

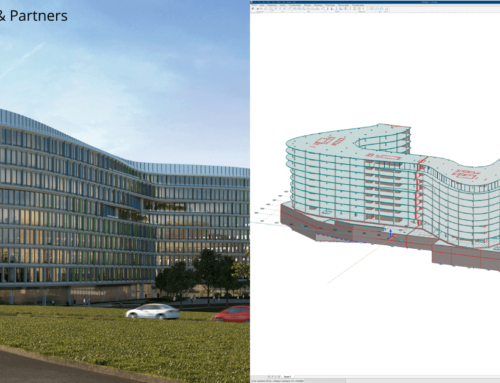

“When it comes to complex projects with dynamic forces and many variables, FEM-Design is a complete solution. It offers the flexibility to handle new challenges and robust tools for standard tasks. We also appreciate its smooth IFC export, which simplifies collaboration with BIM engineers,” concluded Lorenzo Guastalli, structural engineer at UNDEKO.

UNDEKO plans to continue using FEM-Design for future marine and infrastructure projects. The software’s capability to merge dynamic analysis with structural design in a single environment makes it an ideal tool for emerging challenges in aquaculture and coastal engineering.

Client portrait:

UNDEKO AB is a Swedish engineering consultancy specialising in marine infrastructure, aquaculture systems, and environmental solutions. Despite being founded only two years ago, the firm has established a reputation for innovative, sustainable engineering across land and water. With expertise ranging from civil design to ecological impact assessment, UNDEKO delivers solutions that balance technical rigor with environmental responsibility.