Our superuser, Igor Muždeka, Senior Technical Developer at Sweco Norway, has shared with us two great examples of structural engineering automation with FEM-Design API, which he did during his previous job as a Principal Structural Engineer at Norconsult. Our API solution helped him significantly improve structural design efficiency, accuracy, and cost-effectiveness. The projects include two underground steel tanks for wastewater collection and octagonal fish tanks that required complex load calculations.

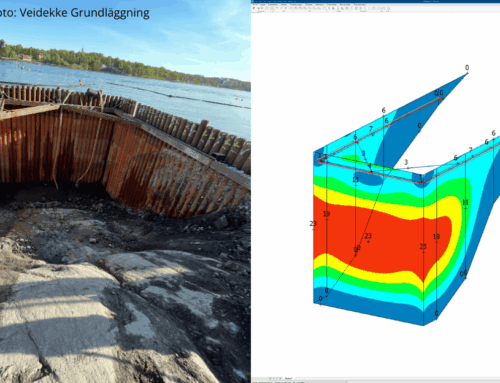

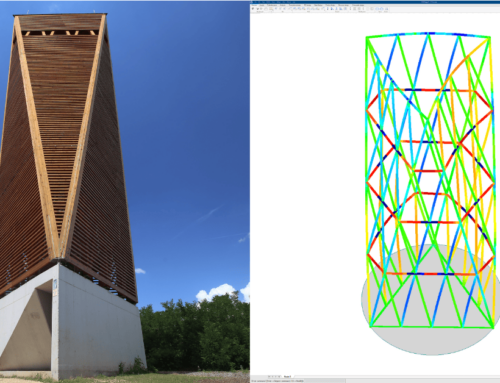

Project 1: Underground steel tanks

The underground steel tanks have a capacity of 50 cubic meters each and were designed to collect wastewater from an industrial zone. Igor used a C# application based on FEM-Design API to determine the effects of different tank diameters on design to propose the best option to the client. For example, one tank had a diameter of 2.40 meters, a length of 10.6 meters, and was located 0.9 meters underground, while the other had a diameter of 3 meters, a length of 6.8 meters, and was positioned 1.4 meters underground. Traffic loads were distributed equally on all sides through the soil.

The benefits of using FEM-Design API for structural engineering automation:

1. Automated tank geometry generation:

- The API streamlined the process of generating tanks with different diameters while maintaining the required 50 cubic meter volume.

- Realistic modelling was achieved, incorporating torispherical heads as per industry standards.

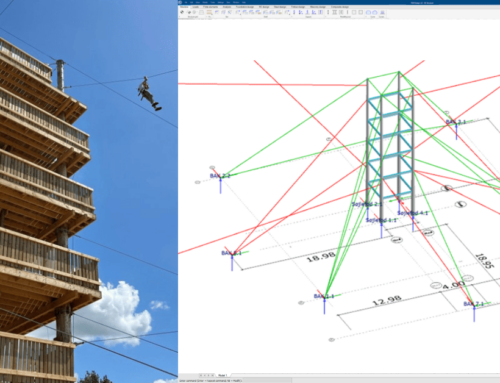

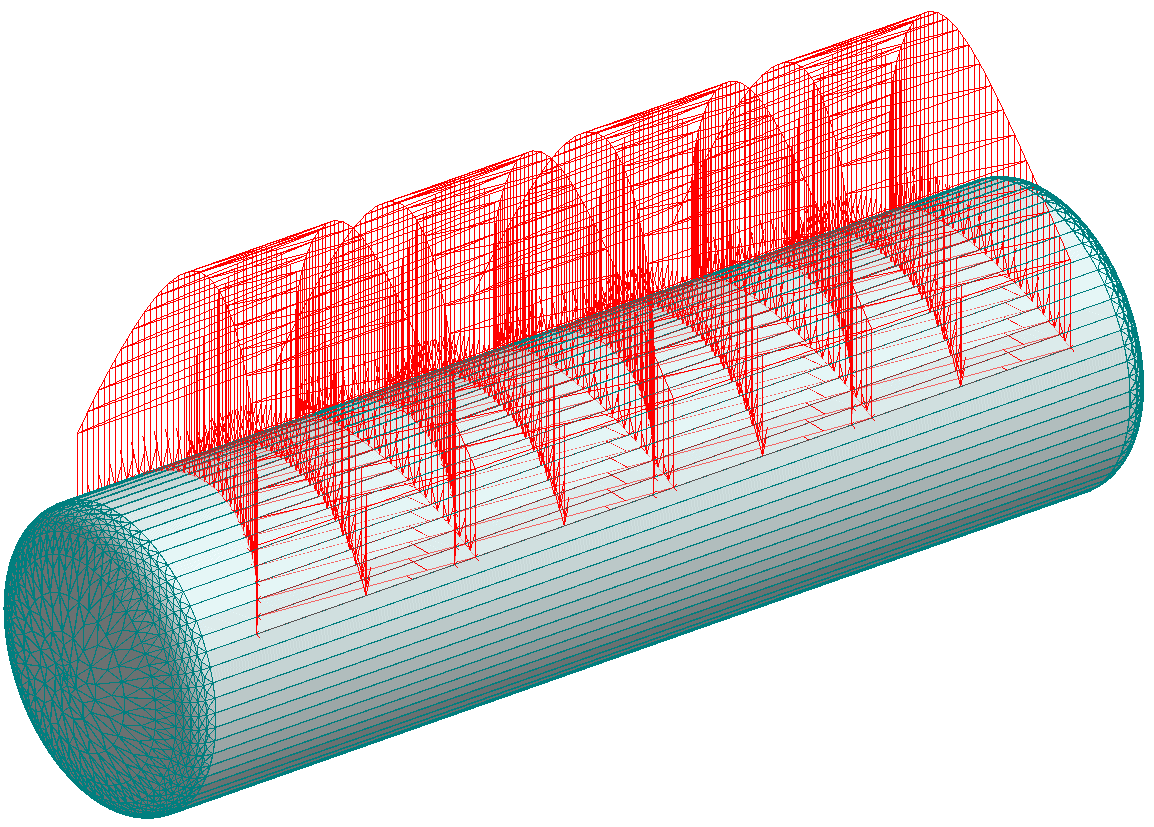

2. Efficient load modelling:

- Traffic load originates from concentrated loads exerted by truck wheels, which then get uniformly distributed through the soil.

- API-assisted modelling ensured accurate load distribution:

- Deeper tank: Overlapping load regions due to a larger distribution area.

- Shallower tank: Higher surface load but no overlapping load zones.

Deeper tank with overlapping load regions

Shallower tank with higher surface load

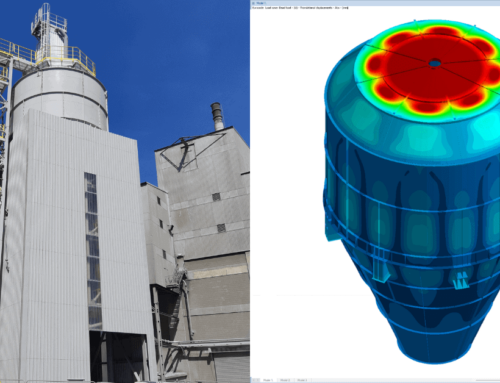

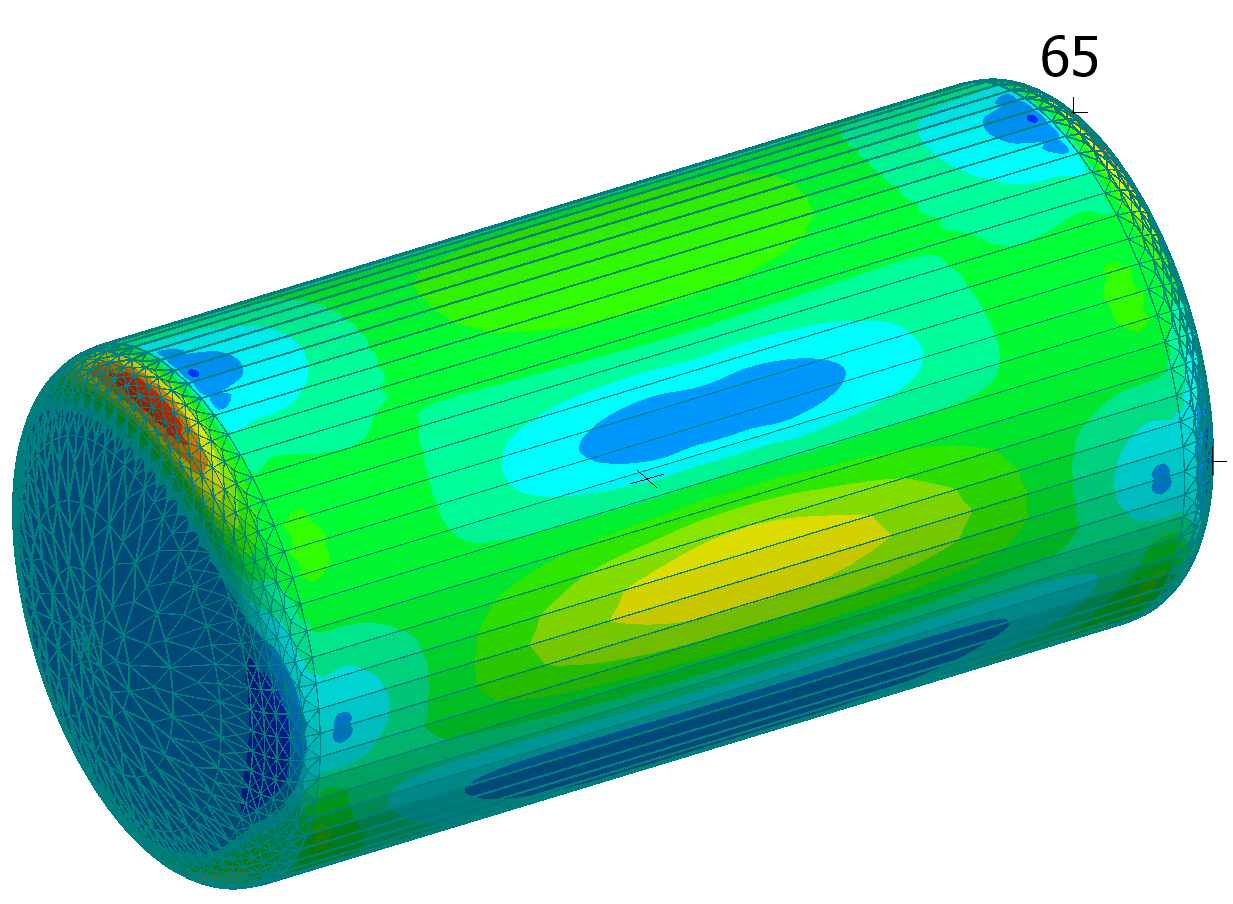

Steel design was performed using FEM-Design.

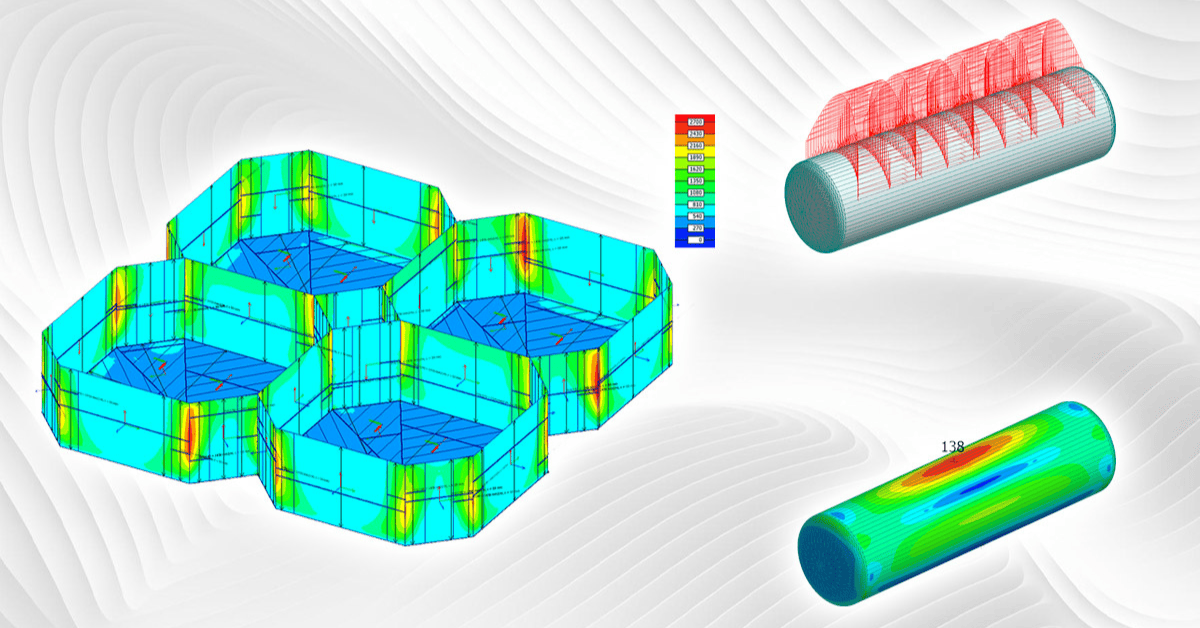

Von Mises membrane stresses

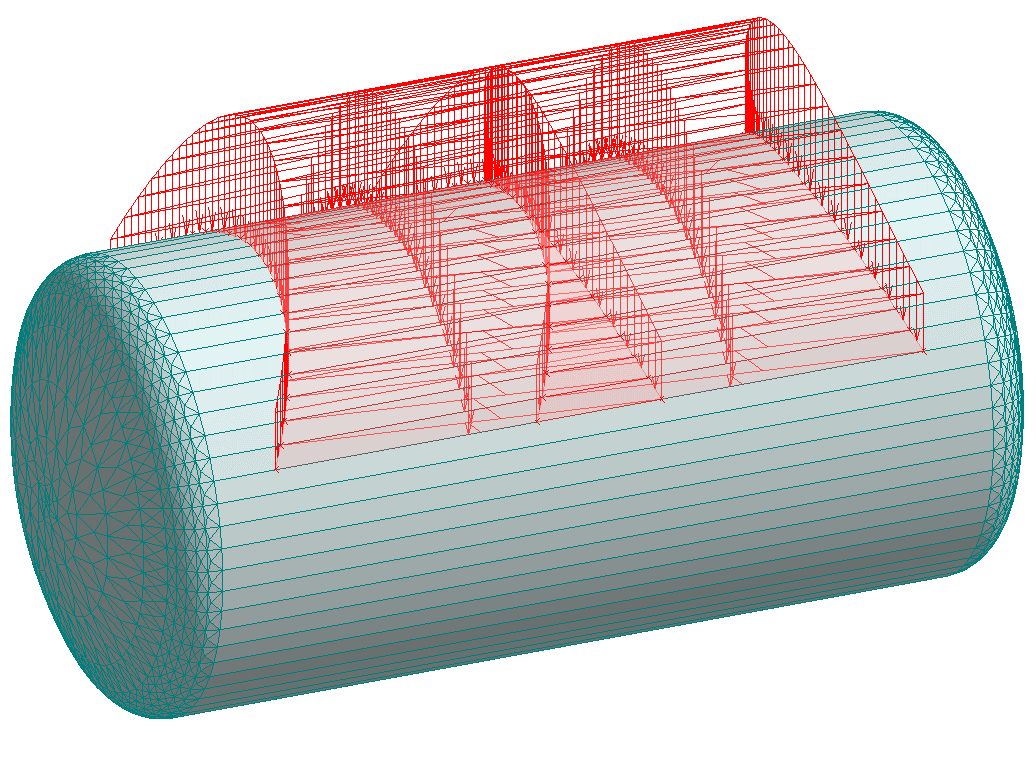

Project 2: Octagonal fish tanks

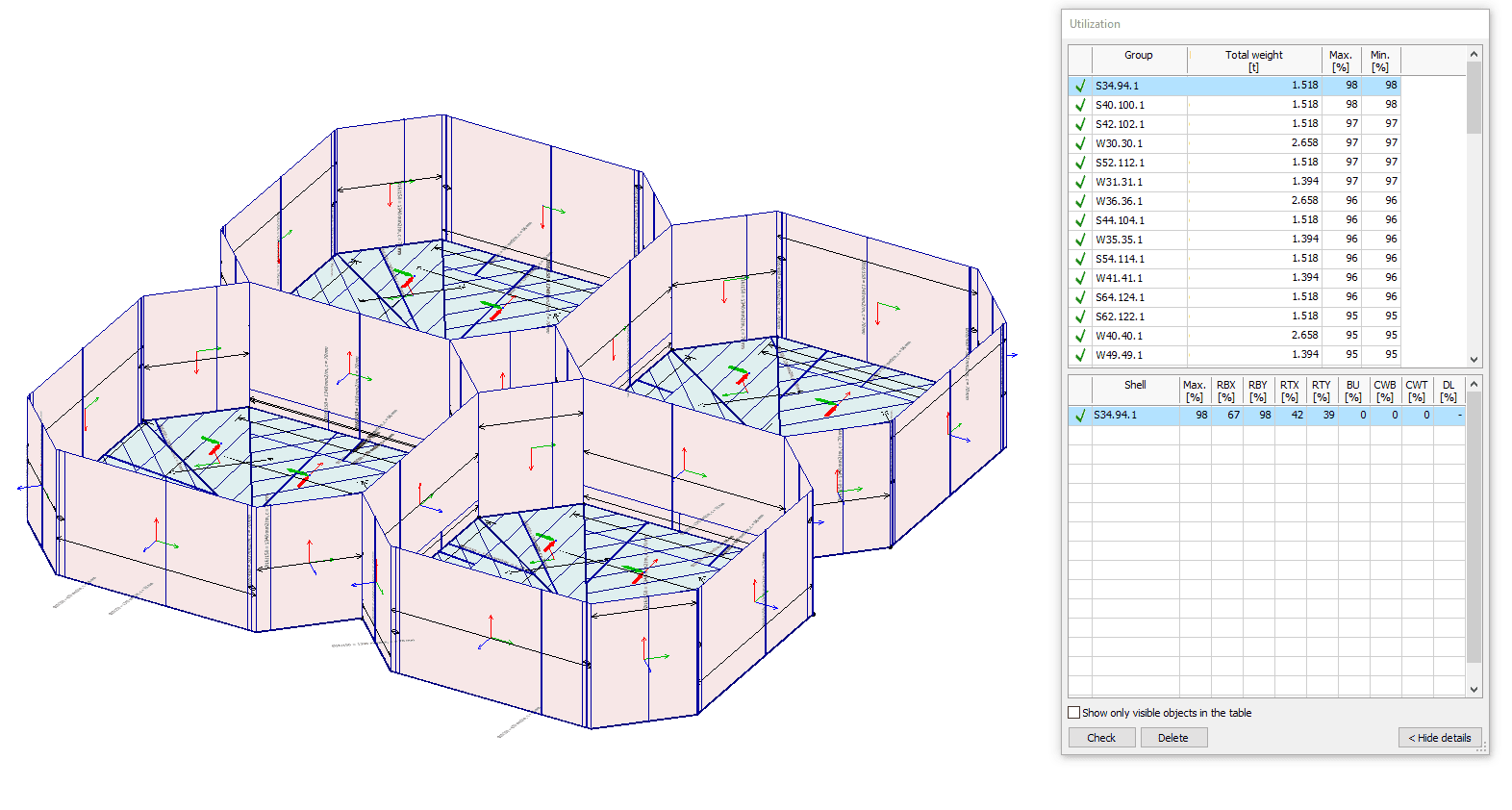

The project involved double and quadruple tank configurations. A key challenge was the management of numerous load combinations, particularly hydrodynamic loads caused by earthquakes. Moreover, the complete design of a fish tank would take about 10 hours. However, by using FEM-Design API, Igor was able to reduce that time to 10 seconds.

The benefits of using FEM-Design API for structural engineering automation:

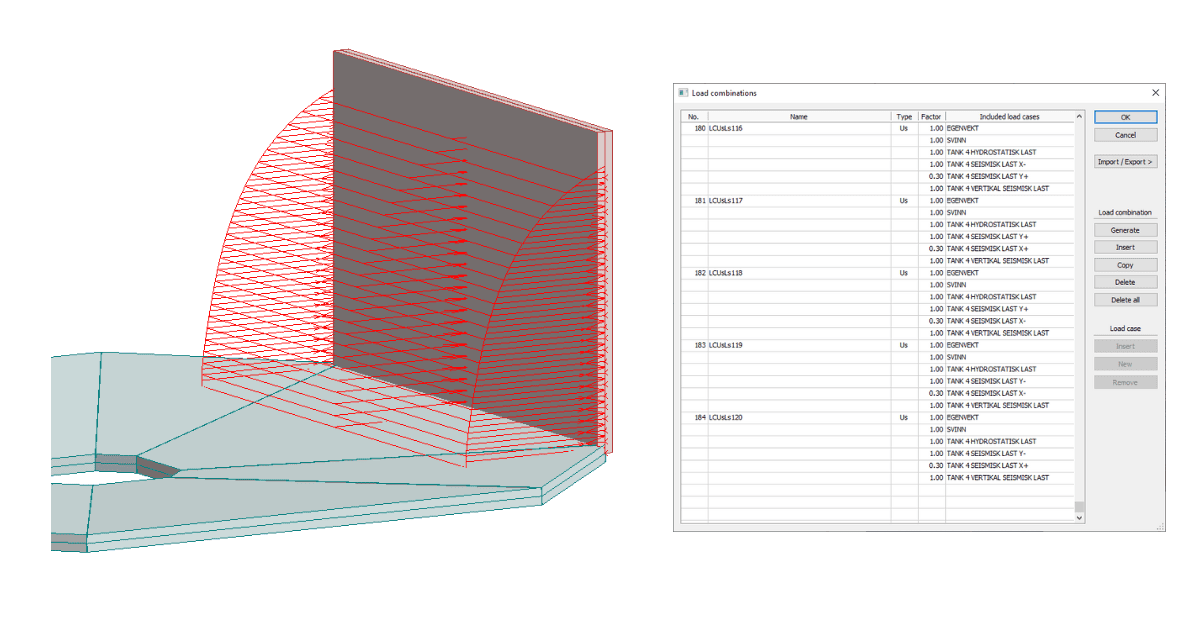

1. Efficient modelling of load combinations:

- The quadruple tank configuration necessitated 184 load combinations, mainly due to hydrodynamic loads during seismic events and situations where some tanks were full and others were empty.

- Manually modelling these combinations in Excel would take a lot of time per tank. FEM-Design API did a complete design of the tank in 10 seconds.

184 load combinations were handled easily

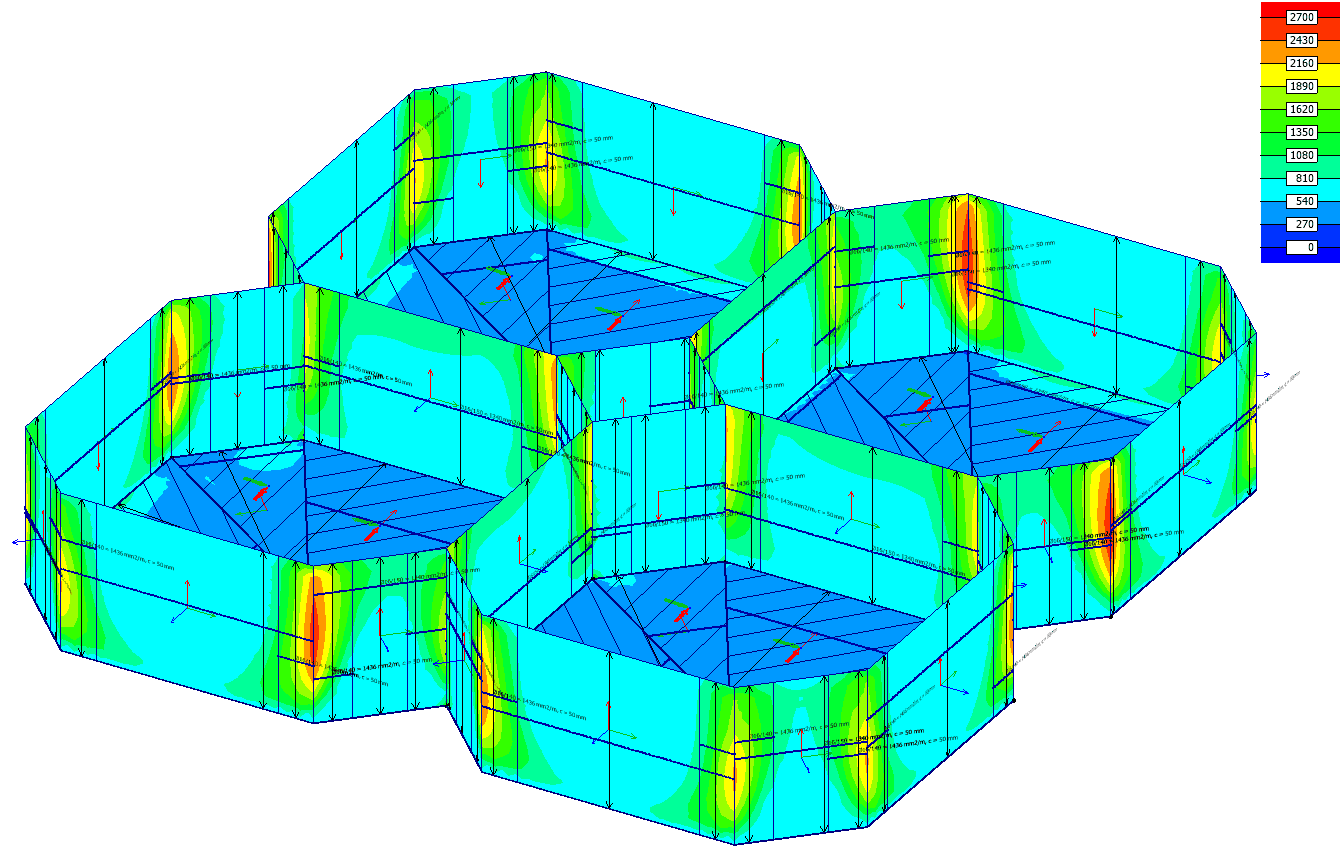

2. Reinforcement optimisation:

- Higher reinforcement requirements at the corners are due to the shape of the tank and the water load. Manually modelling extra corner reinforcement can become cumbersome and prone to errors.

- Instead of applying reinforcement uniformly (simplifying modelling but raising costs), the API enabled precise reinforcement distribution, ensuring material was only used where necessary.

- Through multiple iterations, the most efficient reinforcement layout was determined within an hour, reducing construction costs while maintaining structural integrity.

Reinforcement requirement for the inner side of the walls in horizontal direction

Optimising concrete reinforcement led to reduced costs

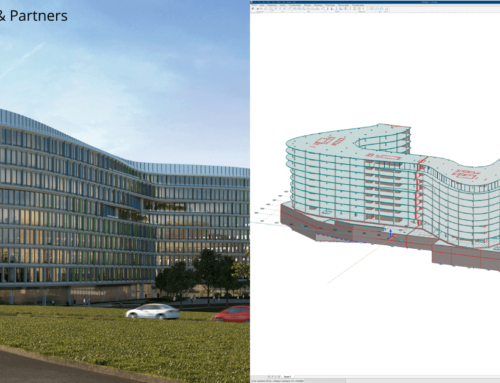

Structural engineering automation with FEM-Design API

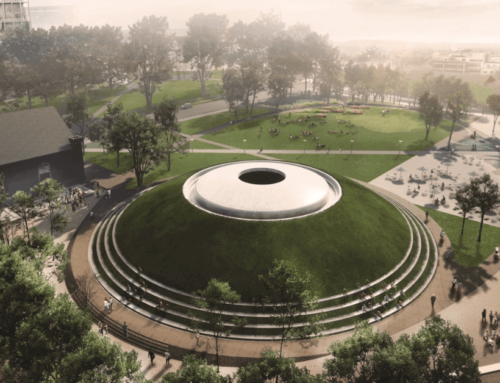

Using FEM-Design API in these projects demonstrates the advantages of automation in structural engineering. It saves significant time by completing modelling and calculations in seconds instead of hours or days. It reduces costs through optimised reinforcement design that minimises material usage while maintaining structural integrity and improves accuracy by enabling more realistic modelling and stress analysis for better decision-making. Reducing material usage also contributes to sustainability efforts and lowers CO2 emissions.

We’re always happy to see our users succeed in their projects using structural engineering automation with FEM-Design API! You can discover more information about the API’s capabilities at this link. We also have a blog and a community forum where you can talk with fellow API enthusiasts, share your projects, and stay updated with new developments.

User portrait

Igor Muždeka is a Senior Technical Developer at Sweco Norway. He holds two master’s degrees and has 8 years of experience as a Structural Design Engineer. He specialises in precast concrete, cast-in-place, and steel structures, including seismic analysis and detail design. He’s an advanced user of FEM-Design and he’s fluent in Norwegian, English, Spanish, and Croatian.