In a short period of time, the innovative wooden bridge BIFROST has gained attention in the construction industry. The creative bridge was developed by a team of engineers, architects, and the City of Stockholm and won an innovation competition. FEM-Design was one of the tools used to realize the idea for the competition entry, where the analysis of the bridge structure was very time efficient.

How can a pedestrian and bicycle bridge be built using lightweight materials that fit in the public space and have minimal impact on the environment? That was the question posed by the InfraLIGHTer Awards innovation competition last year.

One of the entries was BIFROST, an innovative wooden bridge solution that was a collaboration between engineers, architects, a university, and the City of Stockholm. BIFROST won the competition. One of the participants in the winning team was the consulting firm TBS Timber Bridge Specialists.

We developed a modular wooden bridge structure where each part is about four meters long, says Kristoffer Ekholm at TBS. This facilitates both procurement and transportation to the construction site, and the construction also becomes material-efficient. In the event of a repair, damaged parts can be replaced without demolishing the bridge, and no special machinery is needed. The lifespan is extended, reducing the use of the natural resource of wood, which is also environmentally friendly and provides an aesthetically pleasing form.

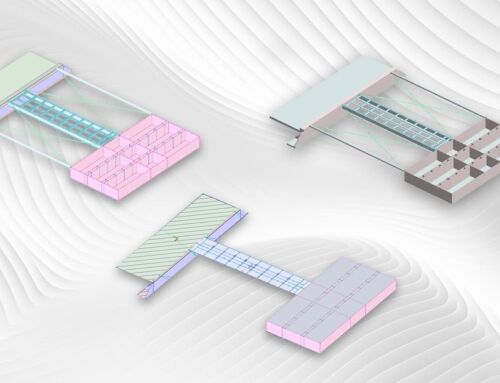

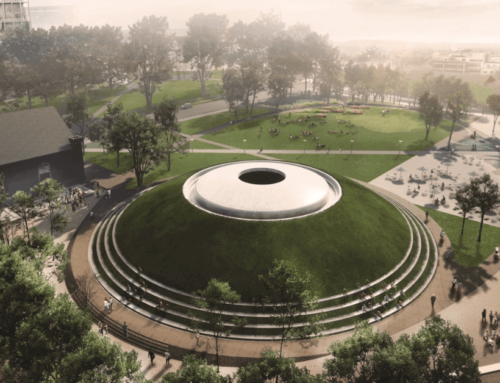

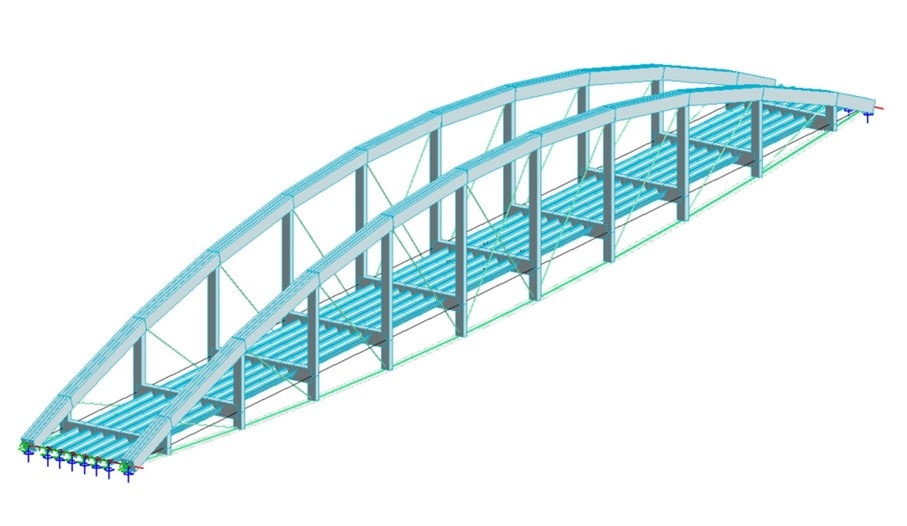

Rendering of the analysis model for BIFROST in FEM-Design. Image: TBS.

Inventive structure

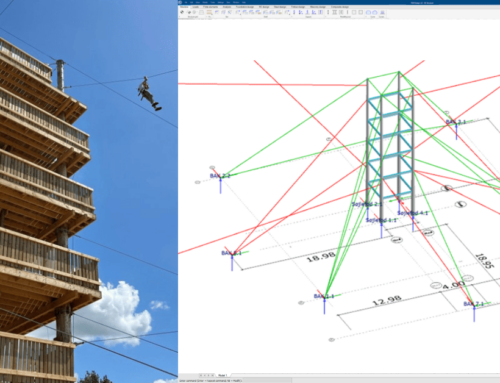

Since BIFROST won the competition, Kristoffer and his three colleagues have been working to turn the concept into a marketable product. The bridge is 40 meters long and consists mostly of wood, laminated timber beams, and remaining parts of steel. The walking surface consists of trapezoidal steel sheeting, also in four-meter lengths, and is clad in wood. To stabilize the structure, there are several steel details, such as wind braces and tie rods. The choice of steel sheeting for the walking surface reduces the weight of the bridge and can handle long spans and high loads with a small amount of steel.

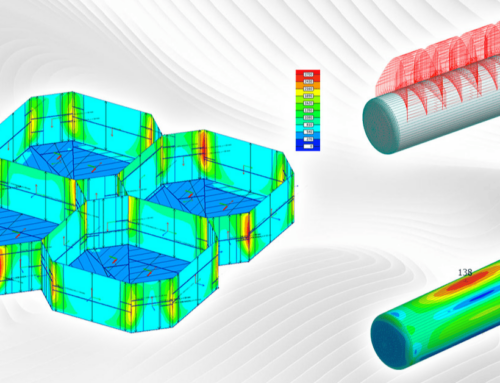

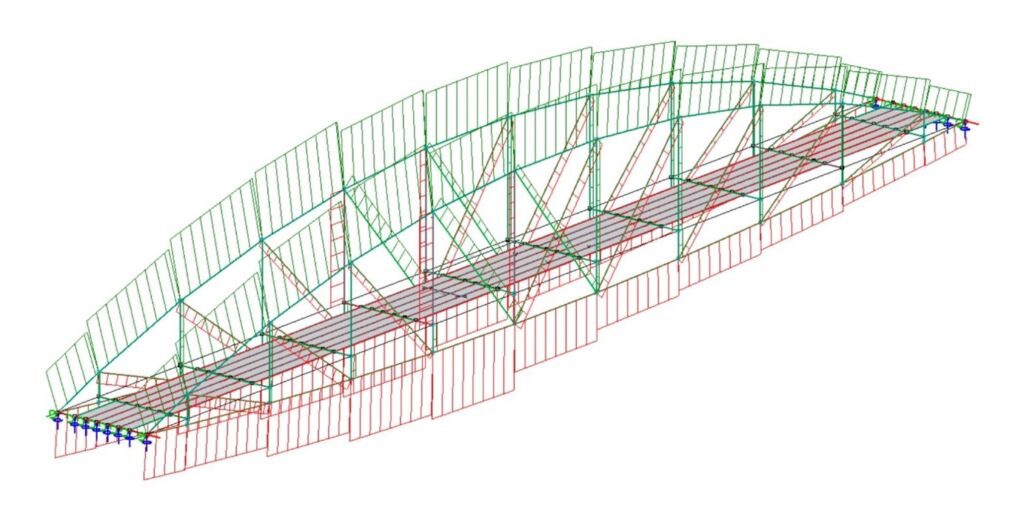

To calculate the load impact, Kristoffer analyzed the structure in FEM-Design, such as static calculations of sectional forces and dynamic analyses of the bridge’s natural frequency, which were used as a basis for design and check against standards and norms.

On a bridge with traffic, there are constantly moving loads where each element is affected differently and exposed to a varying amount of tensile and compressive loads, as well as bending moments. Therefore, the analysis must be done for the entire structure and not each part separately.

I have created my own unique composite cross-sections in FEM-Design, Kristoffer explains. This gives me an efficient way to build up the model using the cross-sections, such as composite glue-laminated beams in different configurations.

Time-efficient FE analysis

It leads to a more efficient workflow. But it’s also the analysis itself that provided time savings.

It’s going very, very fast to run analyses on the bridge, Kristoffer notes. An analysis with moving vehicle loads took only 37 seconds!

But he did not work with a particularly complicated structure with a lot of details such as springs, connections or nonlinear properties.

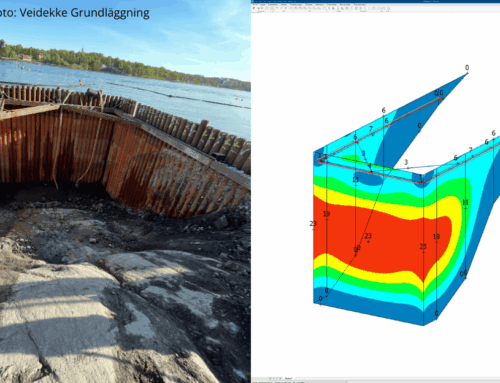

With the new version, FEM-Design 22, the calculation time has been significantly shortened. We were waiting for the new feature to add and remove elements in ’Construction stages’, which we would use in a project where we work with old suspension bridges in Dalarna.

One project is Sweden’s longest suspension bridge in wood with a span of 126 meters, the Kyrkbron in Dala-Floda, which Kristoffer and his colleagues are analyzing for future repairs. What happens to the bridge if a wooden part is removed and needs to be replaced with a new one? What happens to the suspension cables, the roadway, will it slide apart? These necessary questions provide guiding answers in the program for Kristoffer and one of his colleagues who run the analyses.

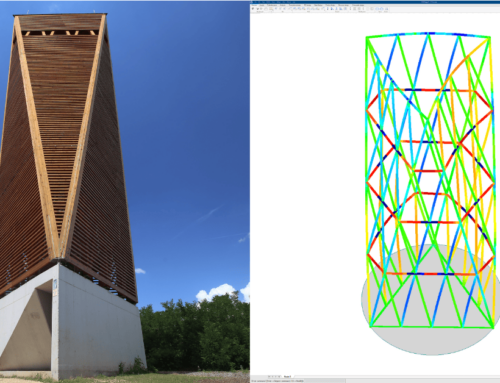

Normal force distribution of calculation results for BIFROST in FEM-Design. Image: TBS.

Easy to create custom bridge variants with the API

BIFROST is a modular bridge solution that can be designed in various ways according to the customer’s needs, Kristoffer emphasizes. The arch of the bridge can be placed under or above the roadway in an under or over-spanned construction, the bridge can have different lengths, widths and heights, and the roadway can have different materials than steel plates and similar properties. This results in a range of variants where the engineers at TBS will benefit from the FEM-Design API.

We are now working on parameterizing the BIFROST project so that we can more easily develop a customer-specific solution with Grasshopper, Rhino, and the API. This will allow us to offer our bridge solution to the market in a manageable way. We see a huge potential in being able to parameterize in this way.

Even though TBS hasn’t had FEM-Design in their program library for very long, they have quickly established good contact with StruSoft’s software developers.

They are responsive and listen to our improvement suggestions, such as the interpretation of long-term deformations in wood.

This is a good relationship that contributes to making FEM-Design an even more efficient tool for users and for TBS on its journey to make it easier for cyclists, pedestrians, as well as car drivers and public transport users to move around on beautiful and functional timber bridges.

Customer portrait

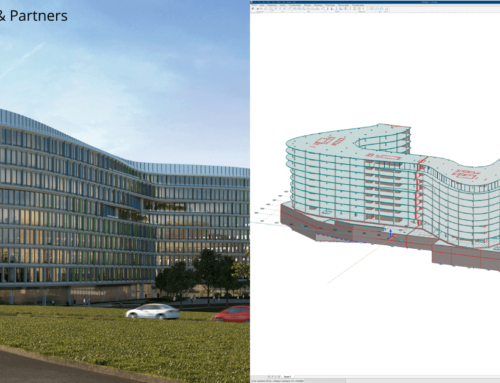

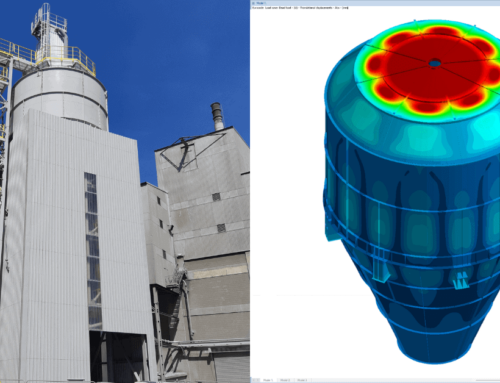

Kristoffer Ekholm. Image: TBS.

Kristoffer Ekholm is a civil engineer and a Ph.D. at Chalmers University of Technology. He received his doctoral degree in structural engineering with a focus on stress-laminated timber bridge decks.

During his civil engineering studies, Kristoffer developed an interest in finite element calculations. He devoted a large part of his doctoral studies to various FE calculations, from complex nonlinear solid models to simpler linear plate analyses. He then developed his own calculation routines for moving loads on orthotropic plates.

After graduation, Kristoffer worked as a bridge designer at Vägverket Konsult, Vectura, and WSP, and was project manager for the design of Hisingsbron in Gothenburg. He is a co-founder and CEO of the consulting company TBS, Timber Bridge Specialists AB, which uses FEM-Design as one of its primary analysis tools.

The BIFROST team consists of TBS Timber Bridge Specialists AB, KTH/Institutionen för Byggvetenskap, Funkia AB, Gaia Architecture AB, and the City of Stockholm.

If you prefer to read this case study in Swedish, please use this link.

© Love Janson