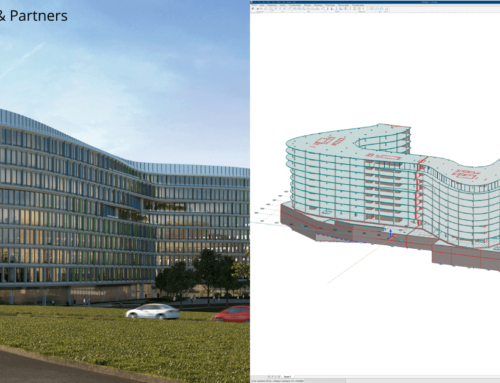

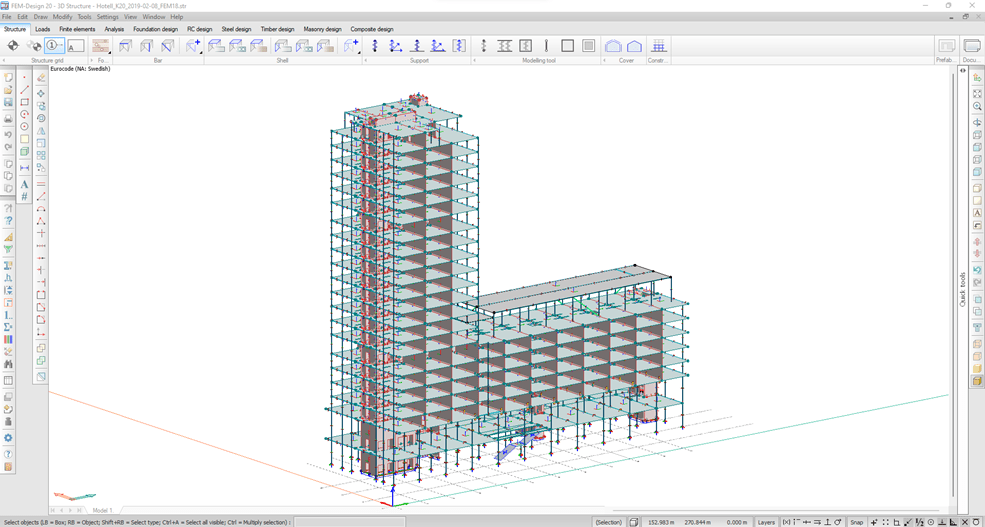

The prefab structure for the elegant Quality Hotel The Weaver in Gothenburg offered several challenges for the engineers at ProDesign. Andreas Dahlgren and Martin Edberg tell the story of their creative solutions using FEM-Design for prefab connections that influence the load distribution in the system.

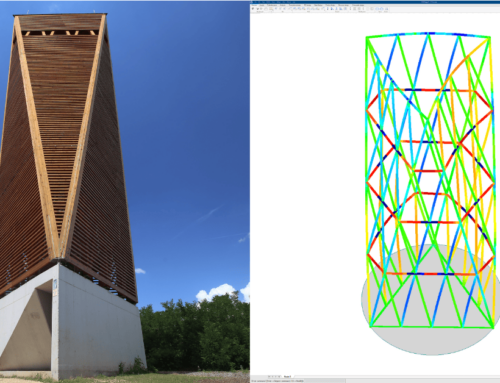

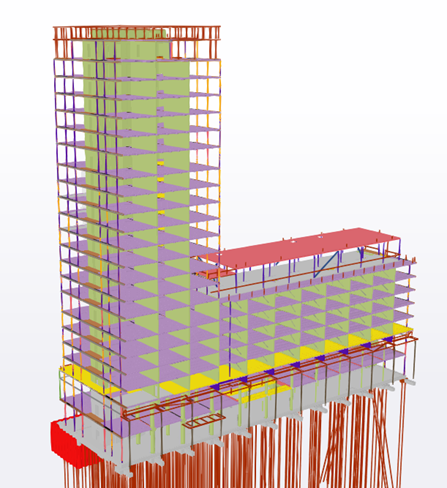

The textile industry has, for many years, influenced the business landscape in Gothenburg. One example is the successful weave industry that grew in the southern part of the city at the beginning of the 20th century. In this same spot, a new hotel opened in 2021, which is called The Weaver. The hotel contains a high-rise part with 21 floors and a lower part. There is also a conference facility and restaurant in the building.

The structure is made of prefabricated concrete elements. The engineering firm ProDesign has been responsible for the structure of the project. The faster the engineers are involved in the project, the better the workflow.

When we are involved from the beginning in a project and can support with our competence and experience, the customer obtains a better result. For example, a more price efficient load bearing structure, says Andreas Dahlgren from ProDesign which is the responsible engineer and technical lead for the structural system on The Weaver.

Advanced analysis and connections between the elements

In every step in the development of the structure, from planning to the design of the element, FEM-Design has been an important tool.

Photo credits: ProDesign

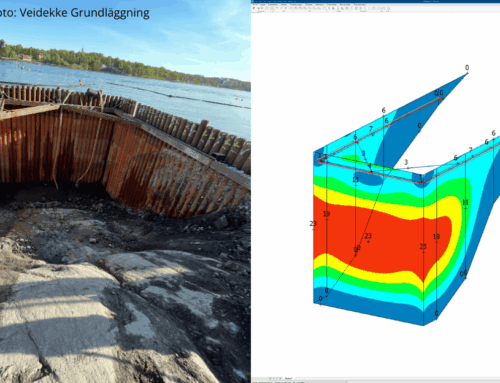

In the project, you work in different steps with the software. First, you evaluate the general behaviour of the structure, followed by a detailed design of the individual elements. The engineers began to model the structure and the loads in FEM-Design to obtain a general idea of the magnitude of the forces in the connection between the elements.

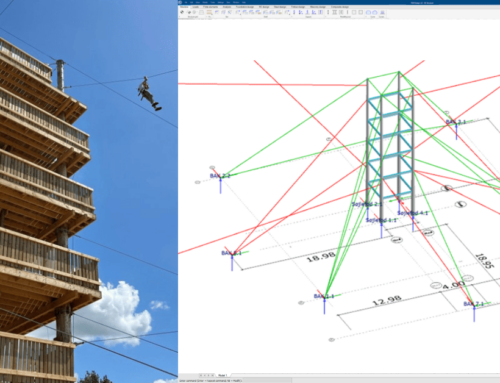

After this, they continued to study the connections in detail. There are thousands of connections in the model, but instead of modelling each individually, the engineers focused on the connections experiencing the largest forces.

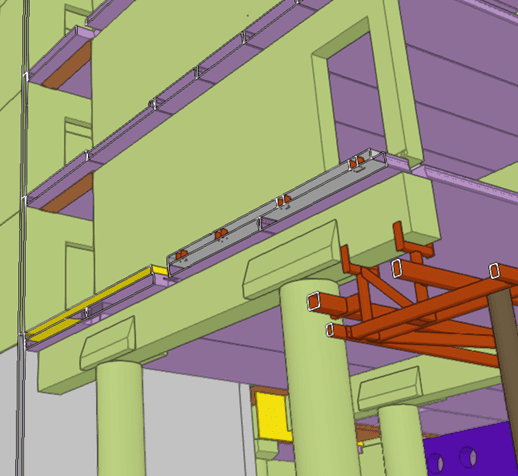

We focused on the connection with the largest forces, says structural engineer Martin Edberg who was responsible for the calculation. If we see a wall that’s experiencing overturning, we insert tension connections between the walls to study the forces obtained from the software to establish the number of connections and what dimension is needed to obtain stability. FEM-Design has been an important tool to calculate the forces in the connections between the elements and to carry out the design to obtain a stable structure that can withstand the forces applied.

When the analysis of the connections was done, the engineers continued the work to design every individual element and, lastly, create shop drawings.

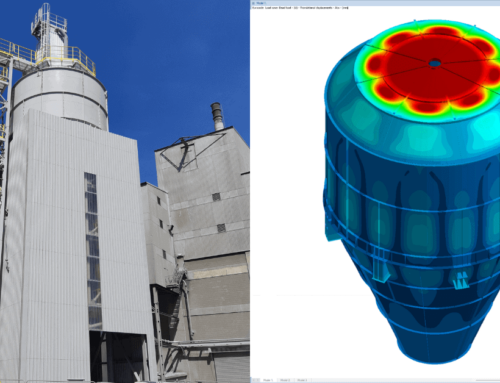

Challenges in load transfer

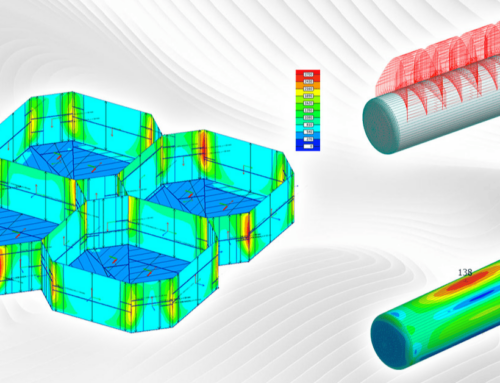

The design of the hotel is made with different requirements in mind that influence the structural system. The rooms are separated with concrete walls, but in the lower storeys, you will find a more open layout to make room for restaurants, conference rooms and such. Because of this, multiple columns carry the load from the above walls.

In the high-rise part of the building there are large forces coming down trough the walls to the beams which is then distributed to the columns. This was the biggest challenge in the project says Andreas.

To distribute the force to the columns we had to come up with wing-like stiffeners for each connection. This special solution was developed and designed in FEM-Design to obtain a connection that could distribute the forces in a satisfying way.

Photo credits: ProDesign

Efficient solutions in the whole process

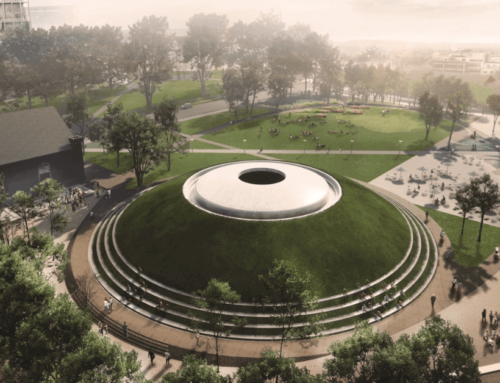

Martin appreciates the workflow where he creates the structure directly in FEM-Design.

I get an understanding of the structure and a feeling for how it acts, he says. Because of this it is beneficial to model the structure yourself from scratch.

Both Andreas and Martin had great utility of the software in the project.

It is extremely valuable, says Martin. The 3D-model gives us the possibility to check load transfers to optimize the complete structure. We save both time and money.

Andreas also talks about how they work with analysing non-reinforced walls in FEM-Design.

In the model we can view how large the forces are. Guided by this we can make decisions if an area needs reinforcement or not, still achieving load bearing capacity and stability. It saves both materials, the environment and money.

Photo credits: ProDesign

FEM-Design has become a companion in the daily work of engineers to obtain a robust and stable structure. A productive relationship between engineering knowledge and the software’s advanced calculation possibilities gives the hotel the required stability and load-bearing capacity.

© Love Janson