BIM in Precast Production Planning has been used on a Paper Mill project in Husum outside Örnsköldsvik, Sweden is expanding into a large and complex construction project.

The precast concrete frame is being manufactured and delivered by Attacus Stomsystem, who has used the IMPACT Precast Planning software to connect the entire workflows, from design, to production, to transport and final assembly.

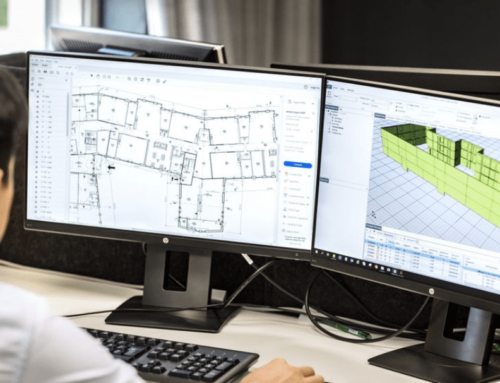

“The IMPACT 3D Project Manager works as a hub and a digital tool for great collaboration to prepare, control and monitor the workflows”, comments, Hanna Zetterholm at Attacus Stomsystem.

“Above all, it is about the exact planning of the buildings on-site. We also use the 3D models for transport planning and to plan the erection and placement of the cranes. Everything takes place in a certain sequence and is dictated by how the construction in Husum develops. The Fixing Teams call for the precast elements to be installed. They must then be ready for delivery and manufacturing. Before this can happen, the design of the elements must be approved for manufacture. A long chain of different activities that all are monitored with IMPACT”.

Colours and Status’ Help Track the Project

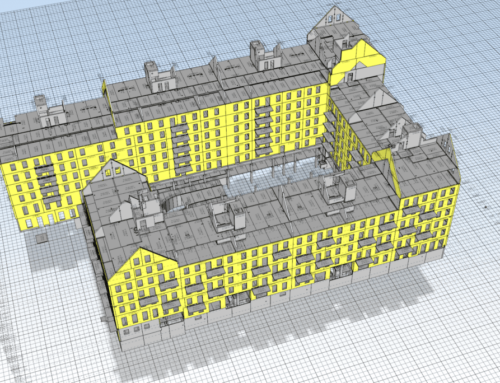

The obvious start of the project was to visualise the 3D model in the IMPACT Project by mapping design data from the External Partner. The 3D model allows intelligent visualisation of the precast elements. With one click, you get all the facts and properties about the element and its unique ID.

To be able to plan future steps in the processes, Hanna and the employees need to examine where all elements are exactly in the production stages. The information is displayed graphically with a total of 16 status’ and each, with its own colour: from inspection and approval; casting with finishing work; storage, right until the element is delivered and assembled on site.

The colours automatically change each time the elements change status. This makes it very easy then to visually follow the development of the element, not just for Hanna and her employees, but also for the Transportation Staff and the Site Installation Team. The 3D model functions as a communication hub with all relevant information.

They also buy in some elements from an External Partner that have been given their own colour, e.g. purple, which is easy to identify because they do not belong to their in-house production.

The Designers from the External Partner also have access to the live IMPACT Project Manager model and benefit from the status changes too. From time to time, when changes occur in the elements, the Designer can enter the Project Manager 3D Model and study the status’, to see whether the element is cast and whether it is possible to change the design. It simplifies and facilitates the work.

BIM in Precast Production Planning | Transport in full 3D

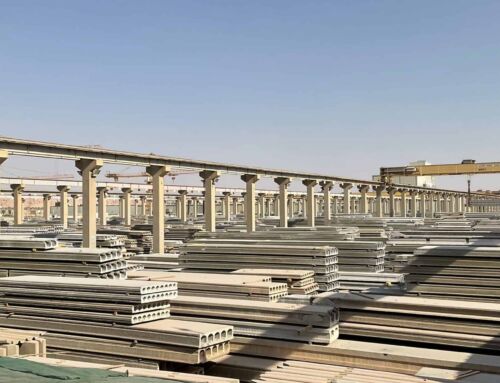

The IMPACT Project Manager 3D Model also plays an important role when the precast elements are to be planned for transportation on the 200km long road between Attacus Stomsystem’s factory in Strömsund and the paper mill in Örnsköldsvik. The schedule is planned exactly to the Site Team’s requirements. The transport planning in IMPACT now shows a different colour scheme of the elements in the model than the production planning. The colour code has a different task than marking the status’. Instead, IMPACT shows the elements that should go on the same delivery vehicle.

The Transport Manager sees the elements in the 3D model that are to be delivered according to their size and weight. He can plan which elements are to be included in the same load according to their dimensions and each load gets its own unique colour. This ensures every trailer is filled; not one goes half full and they reduce the transportation costs.

Each element in the model also has a unique transport number too. With IMPACT, the elements are also presented in a list format, by properties. By filtering out the upcoming deliveries during the next week, it is easier for the Transport Manager to get an overview and to decide when best for the deliveries to take place.

3D Crane Planning Supports the Building Erection Sequence

When the elements are ready to be assembled on-site, this is also planned within the IMPACT Project Manager and an Erection ID controls which order their installation should take place. The 3D Crane Planning function plays an important role here.

In IMPACT, they can decide the best position where the two cranes should be placed. They find zones for unloading the elements and where the truck should be parked. In IMPACT, they can also see the span of the cranes and whether a crane can lift a heavier element and plan accordingly.

There are small margins for error with many Actors and People in the field at the same time. The assembly must be adapted to the Landscape that can be used, as the elements are not offloaded and stored but taken directly from the truck and installed immediately in the final position.

IMPACT as a Collaboration Hub

Both Hanna; the Employees in different departments and Suppliers get an overall picture of the Project and can work proactively to pre-empt and avoid problems and challenges.

“The IMPACT 3D Model works as a hub…”, says Hanna. “…a fantastic tool for BIM in Precast Production Planning where each Actor in the Project has access to the same real-time information. This is necessary because we need to coordinate the work daily and at the same time create an understanding of all our process.

An information flow that is controlled in this way, using IMPACT, has positive effects on the planning of all the various phases of the project and that the implementation takes place smoothly. IMPACT is an important cog in the complex precast process and increases the chances that everything will be ready on time.”

For further details on Attacus Stomsystemm please visit their website by clicking here.

For more details on IMPACT please visit the webpage by clicking here.