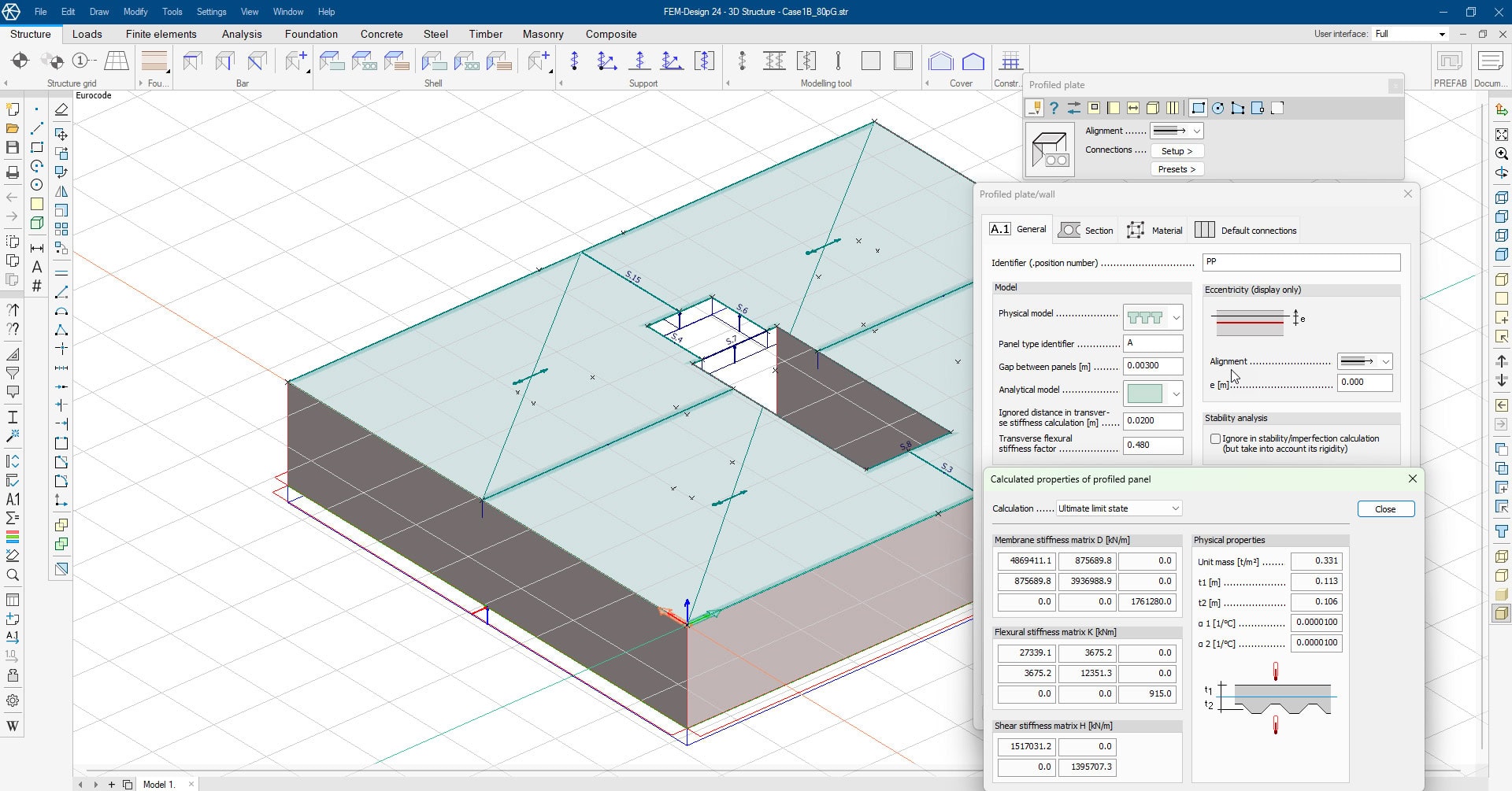

StruSoft is an innovative Swedish company with more than 40 years of experience developing specialist Structural Design Software including advanced 3D FEM and Finite Element Analysis (FEA), Precast BIM Software and Building Energy Analysis Software.

Our hallmark is developing outstanding software performance in combination with advanced features, user-friendly interfaces and unrivalled support. We are trusted by 2,000+ Clients with 20,000+ Users in 40+ Countries.

All customers receive unlimited support included in the cost of the software. We invest heavily in support and development of all our structural design software to ensure you get the possible service and support for both the use of the software and also the workflow for your projects. Create a support ticket by clicking on the Get Support icon above.

We invest a huge amount of time and resources in our separate Wiki knowledge base websites for 4 of our main software: FEM-Design, IMPACT, PRE-Stress and WIN-Statik. The Wikis support you with in depth knowledge and theory on the software together with all the latest release news and features. You can find a link to the 4 x Wikis by clicking here.