For the last six months, our colleague Thomas Gitsas has had the pleasure of cooperating with GRUPO PACADAR and PACADAR U.K. LIMITED, implementing our IMPACT software for their industrial projects in their factory in the United Kingdom. During this period, he found out and was slightly surprised at how many new things he has learned concerning projects that StruSoft does not usually apply IMPACT to. Thomas, who works as Business Development Manager in StruSoft for our Precast Business Unit, realised that industrial and commercial precast projects are very different – even though the process is the same. Therefore, he decided to share some of his thoughts through this post and shed some light on the main differences between the two. However, due to his limited experience in industrial projects, Thomas invited one of the new users of our Precast Software for Design, Production & Projects – IMPACT. He asked the company, Grupo Pacadar, to participate in an interview to help him point out the project differences and the advantages of IMPACT in industrial projects.

The person he bought in is Mr. Ramaseshu Kittur Srinivasan, who has been working as the Head of Special Projects and Wind Tower Operations of the Pacadar group for the last five years and has many years of experience in different management positions. Originating from India, he has worked on special engineering projects multi-nationally and has vast experience in the many aspects of our field. He currently lives in Madrid, where he is responsible for managing efficiently many Industrial Precast projects for the Pacadar Group, such as bridges and tunnels (segments).

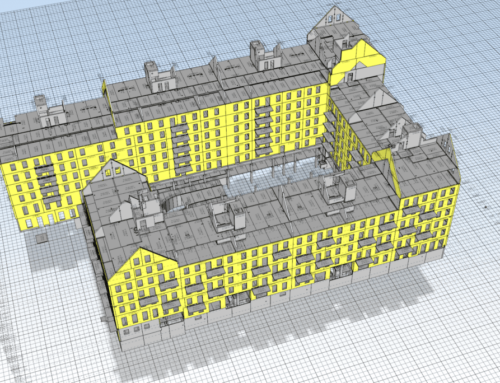

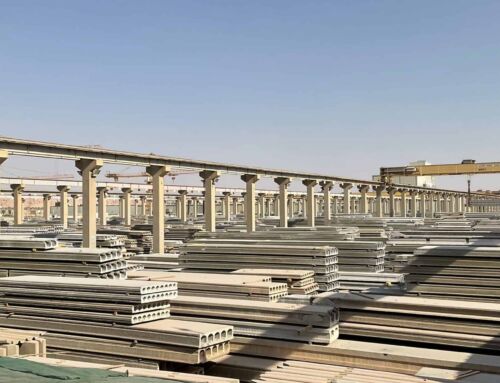

Picture from © Grupo PACADAR's homepage (www.pacadar.com)

The interview

Good morning Ram! Can you please tell me a few things about the Pacadar group and your values as a company?

R: Good morning, Thomas! Grupo Pacadar has 70+ years of experience in all infrastructure markets and segments and can help with any type of project to ensure you have the right products. Our people have extensive experience and access to resources and can help with all aspects of product selection, installation, and support.

With a great presence in almost every continent in the world, we can offer construction solutions that adjust perfectly to the needs of any project in the most diverse sectors, while meeting the highest quality standards. We as the Pacadar Group always honour our commitment to QUALITY.

Now to the main Question: What are the main differences between commercial and industrial Precast Projects?

R: Look, the main difference is the size of a precast element that has to be created/designed. In a commercial precast project, an element can weigh max around 20-25 tons, according to the capacity of your cranes; in industrial precast, an element can weigh around 100 tons with a length of 15 meters or bigger. Now, taking the above as a fact, you can understand that the design, the logistics, and the planning of an element like that are much different than a commercial wall element. However, the workflow remains the same, but the scale is way bigger.

What is the biggest challenge in an industrial precast project?

R: The enormity of the design. The element is so big that its design, production, quality control, and transportation take a lot of time to plan – in advance.

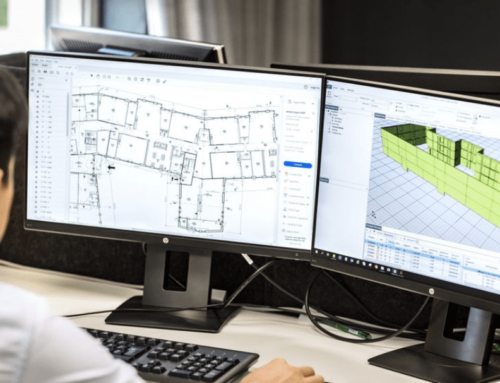

What has IMPACT helped you the most with, since you started implementing it?

R: We are using IMPACT mostly for the element control system applied to the cast planning module. The bridge project that we are currently using IMPACT for, has a lot of different documentation needs when it comes to quality control. Therefore, IMPACT’s Database helps store the data digitally and allows us to manage the information internally for the whole company in real time.

Why did you choose IMPACT in the first place?

R: Honestly, the real reason why we chose IMPACT is that it is a software adjustable to our projects. It is very important for us that we do not have to customize it in order to start the implementation process. There were no discussions on how to perform the precast process, where we start, and where we end. Everything is already there and we could start right away! The only difference is just how big our elements are!

I know you are a fairly new customer, but what is your experience with StruSoft so far?

– R: Very friendly. Honestly, we are still only in the beginning, and when I talk about interaction I always know that interaction goes both ways. First, we need to understand the issues (if any) and the software to its fullest, and then we need to communicate it properly to StruSoft in order to get the help needed. So far so good, though!

-T (Author): I think you hit the nail right in the head. When the customer puts in the effort and understands the software during the implementation/training period, then the interaction becomes much more effective. What I mean is that from that point on, the cooperation can advance the projects and therefore the whole business to a higher level very quickly. Putting in more effort at the start will benefit your company a lot in the future.

Pictures from © Grupo PACADAR's homepage (www.pacadar.com)

A big thanks to Mr. Ramasheshu for his time and effort, and also a big thanks to Grupo PACADAR for allowing us to interview one of their employees. If you would like to learn & read more about GRUPO PACADAR, please visit their homepage, PACADAR: Precast concrete solutions.

If you have any further questions, or you would like to know more about IMPACT Precast – and the implementation of our software for larger projects, do not hesitate to contact Thomas, or you can always visit our main page, Precast Software for Design, Production & Projects | IMPACT | StruSoft

Thomas Gitsas

Would you like to learn more about IMPACT software and perhaps be interested in receiving a free demo and consultation on how we can support your Precast business? Then don’t hesitate to Book a 1:1 Teams meeting withThomas – he will be happy to help you. Or you can follow the form below to Book a Demo.