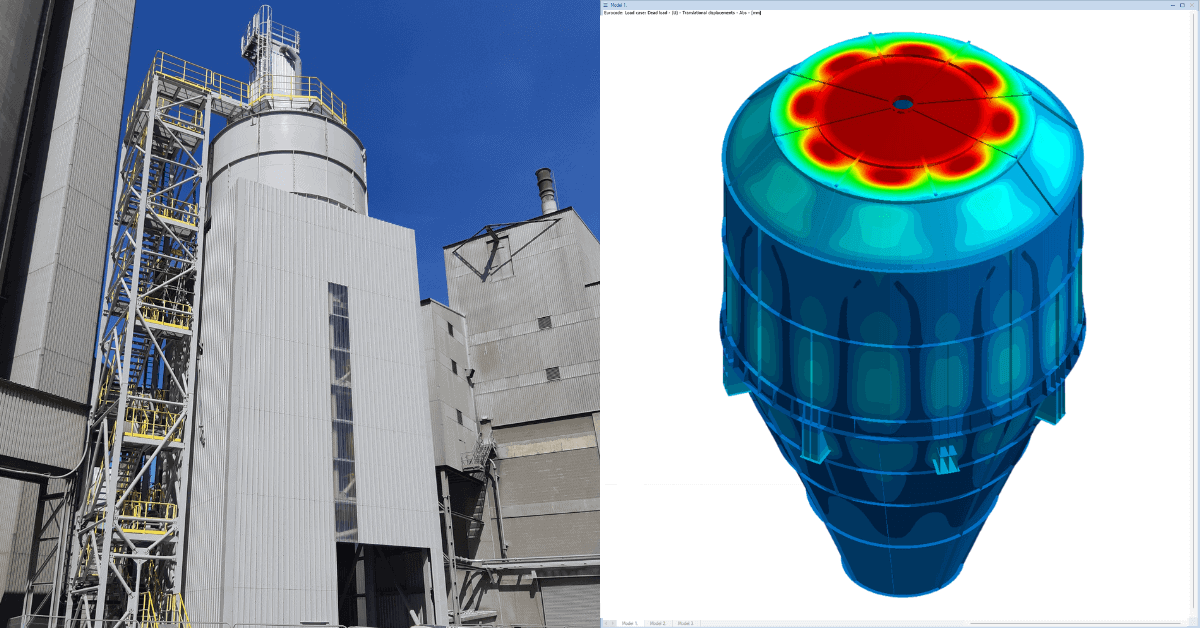

In Buxton, England, inside a cement plant, there is a silo for storing bypass dust that is supported by a steel structure and was designed with FEM-Design. The client, A TEC Group, an Austrian engineering and technology company, contracted GMBS Design for complete structural engineering services.

GMBS Design is a Hungarian-owned engineering company with a knack for complex projects. They are not a typical firm that focuses only on the engineering aspect of a project, but rather manufacturing and production of the design as well. Moreover, they are present in various industries, such as Cement & Lime, Metals & Mining or in the Pulp and Paper industry.

Project overview

The project was done in 2021, and the objective was the complete structural engineering of the steel silo and its supporting structure made of steel as well. The silo is located inside a cement plant, and the purpose was to decrease the usage of fossil fuels. The engineers at GMBS Design handled the steel structure analysis and design of the whole project.

Challenges related to calculations and construction

There were two main challenges that the team at GMBS Design had to overcome to be successful in their work: the calculations and the construction itself.

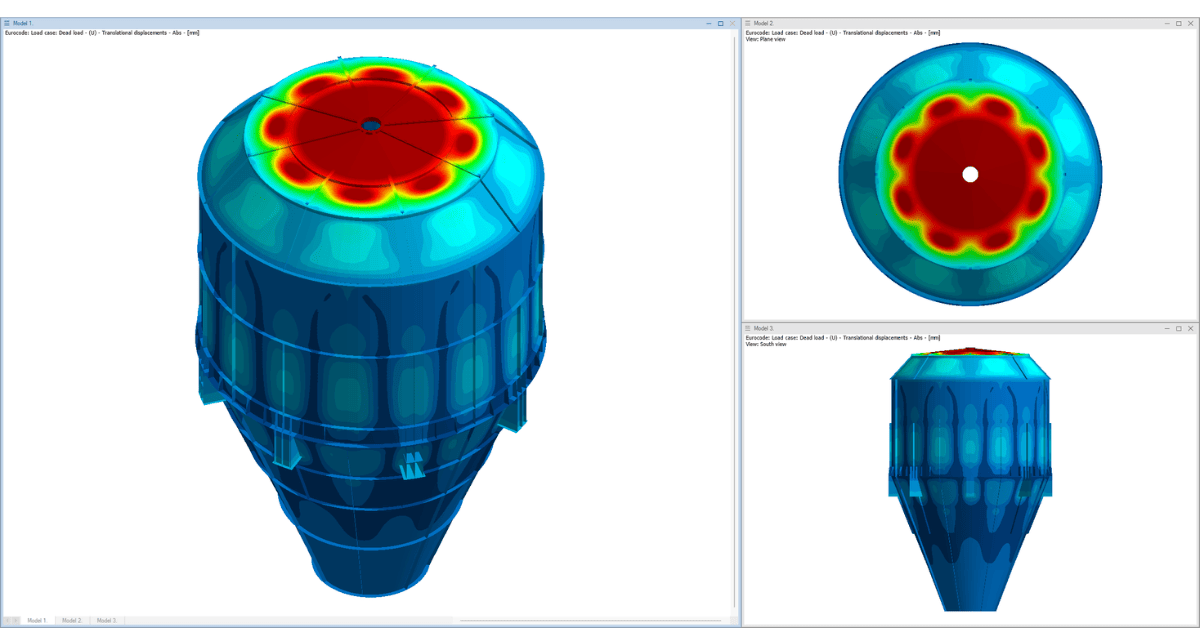

“We chose FEM-Design because we had good experience with it from previous projects, having used it to calculate plated structures in the past. The main challenge in this bypass dust silo project was to get accurate results on the shell, joints forces, and on the area of the support points. These places were critical for the project’s success. We used some hand calculations as well, but for the most complex areas we needed FEM-Design to get maximum accuracy. Considering that the silo lies on a bigger steel structure, which we also designed, FEM-Design played an essential role as the mutual ground in the analysis of both structures,” says Gábor Galambos, Key Account Manager and owner of GMBS Design.

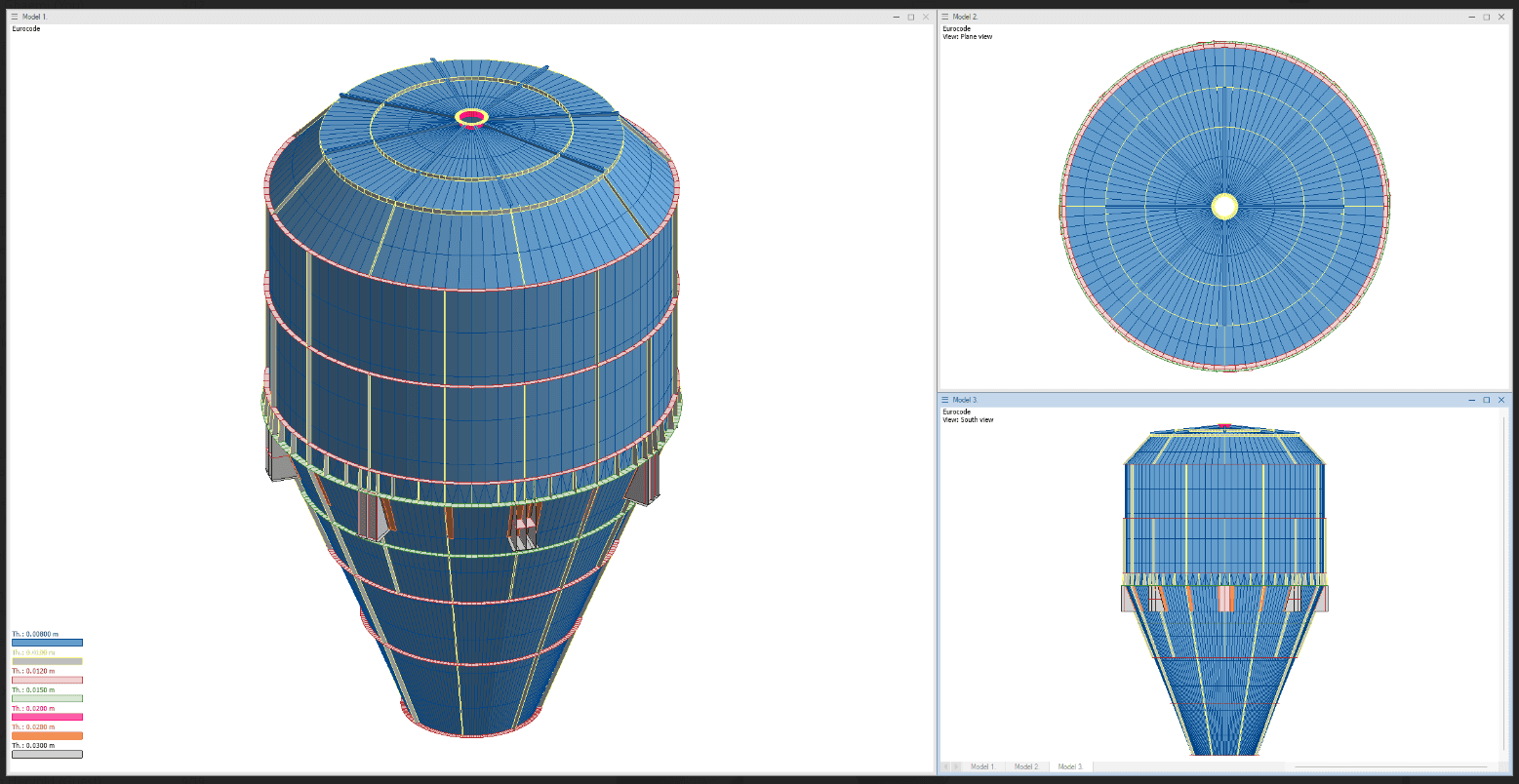

FEM-Design input model of the silo

The second challenge from the calculations point of view was to make a good arrangement of the beams to ensure that under the silo’s support points there is even stiffness of the beams. This was done to have the same results at all eight support points to avoid an overload.

“Without FEM-Design, we would have struggled to get accurate results on the bottlenecks, such as support points or the joints. We enjoyed the flexibility and versatility provided by the software, as it was necessary during the iterative process until we got the results we needed. The most important thing for us was to get these accurate results and do it as efficiently as possible.”

The result of calculations in FEM-Design

They overcame the calculation challenges with the help of FEM-Design, but the project also posed some construction challenges.

“There were some challenges from the construction point of view as well. In general, the silo was designed to build up from transportable-sized parts as it was manufactured in Turkey and had to be shipped to England in containers. The elements were bolted together on site, but this was only a temporary solution to make all the final welds from inside the silo. It became a welded construction in the end, with only two cross sections which remained as bolted,” adds Gábor.

The reasons they chose FEM-Design for steel structure analysis

The engineers at GMBS Design have used our software on previous occasions with great success. For example, they had similar calculation challenges for another alternative fuel project that involved ducts and pipes. The more they used FEM-Design, the more they got accustomed to it and could use it optimally.

For the engineers at GMBS Design, FEM-Design is essential for complex calculations. They have other industry-standard software for simpler analysis of beams or columns, but those are not capable of complex calculations like they need for shell structures.

“With FEM-Design, we can solve these issues quite easily, and we like the ability to combine the shell structure and the bar elements as well. We can easily calculate the stresses of the shell. Moreover, we like to work with FEM-Design for nonlinear calculation, stability analysis, and take advantage of the various mesh settings. We like how FEM-Design creates reliable meshes and that we can do manual adjustments on them. These are the main reasons that made us choose FEM-Design for these kinds of projects,” says Gábor.

FEM-Design also integrated well within the established workflow used by the engineers. For example, their workflow is to create geometry in software such as AutoCAD. They do the geometry in 2D or even 3D in AutoCAD and then import it into FEM-Design. Afterwards, they can use the geometry from AutoCAD as inspiration in the background or even as “live” model that they could turn on and off during the design process in FEM-Design.

About the collaboration with StruSoft in general

“When we had any issues or needed some tips, the support team was very helpful and fast to get us a good solution,” says Gábor. “Also, we are using FEM-Design for concrete elements or prefabricated concrete element design, and then we frequently go to webinars or participate in online courses to get more out of the software. I think that our collaboration is good and looking forward to continuing like this,” he concludes.

Customer portrait: GMBS Design Kft.

GMBS Design Kft. is a Hungarian-owned engineering company that focuses on engineering for industrial projects. They are primarily active on the European market and work with various clients, such as cement factories, technology suppliers in the energy and mining sectors. Besides the focus on engineering services, the company has recently started to do projects that involve organizing the manufacturing and erections works as well, extending their services to cover every step of the building process.

Presently, the team has 7 people: 6 engineers and one administrative personnel. They are also using freelancers from time to time. At peak moments, the team comprises about 10 engineers working on several projects. Gábor Galambos is the owner and manager of the company. He started the company in 2019 and was the only employee then.

Count on FEM-Design for steel structure analysis

Have we made you curious about the capabilities of the steel design module in FEM-Design? It’s one of the most sought-after modules in FEM-Design for its fast automatic analysis & design that helps you find the most suitable steel bar cross-sections according to Eurocode 3, powerful fire design, 3D frame and truss modeling, and more! You can read more here.

You can always check the steel user manual on YouTube if you prefer video content.

Discover how other companies are using FEM-Design’s 3D steel design module to full potential by reading this case study.

Steel structure analysis is easy and fun to do if you count on FEM-Design. We look forward to seeing what amazing projects you will do with the help of FEM-Design’s steel design module.