Structural Analysis Software | FEM-Design

FEM-Design is an advanced and intuitive structural analysis software. We support all aspects of your structural engineering requirements: from 3D modelling, design and finite element analysis (FEA) of concrete, steel, timber, composite, masonry and foundation structures. All calculations are performed to Eurocode standards, with some specific National annexes.

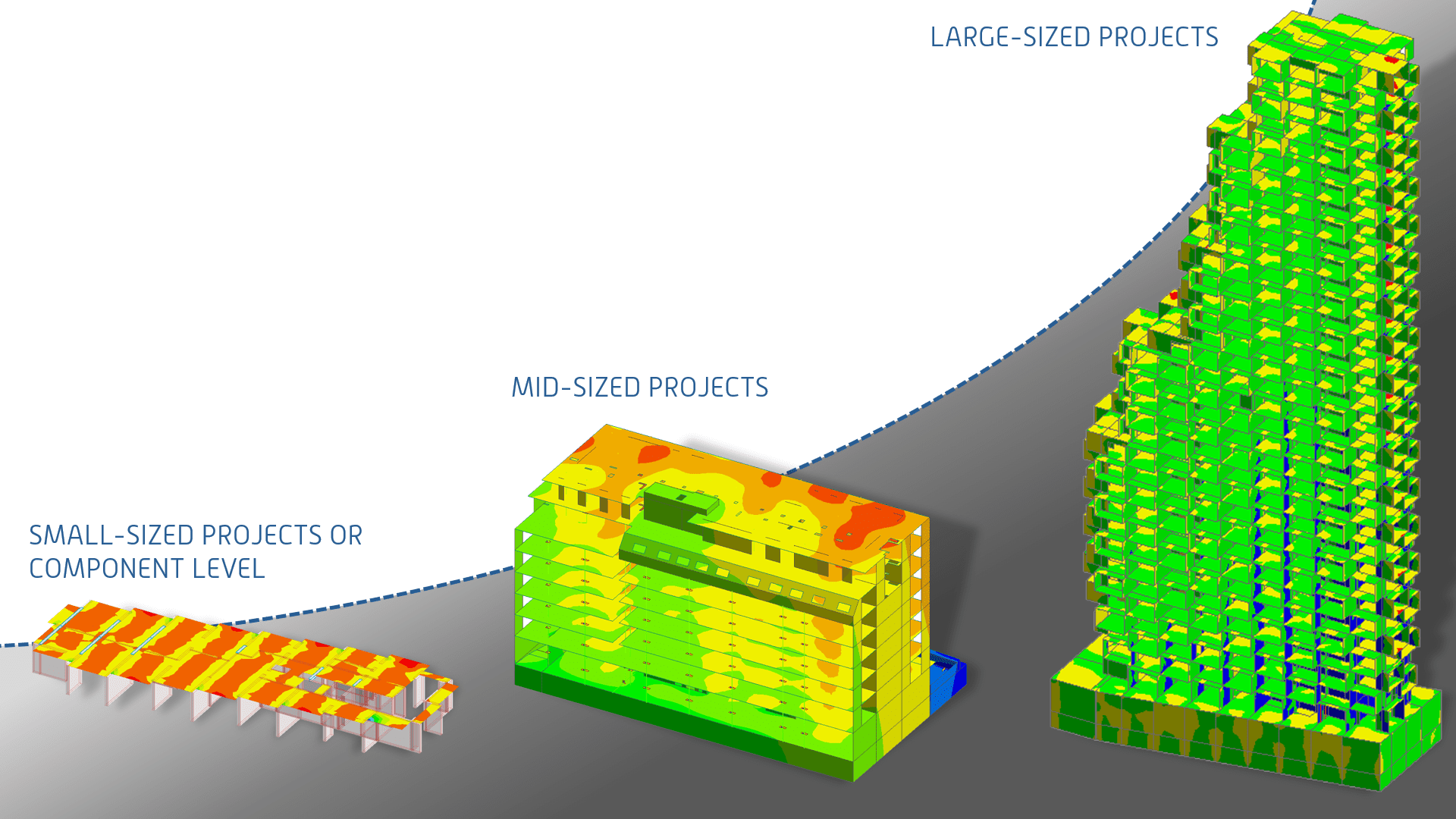

The quick and easy nature of FEM-Design makes it an ideal choice for all types of construction tasks, from single element design to global stability analysis of large buildings, making it the best practical program for structural engineers to use for their day to day tasks. Moreover, it helps bridge engineers with a dedicated module for designing road, railway, and pedestrian bridges.

Structural Analysis Software for any size and type of structure. In accordance to Eurocode.

The FEM-Design Calculation Engine allows you to perform structural analysis of both simple, single elements, as well as complex spatial structures. These include static and stability analysis (such as imperfections), load combinations, construction stages, plastic analysis, and many types of dynamic analysis, such as seismic, footfall and time history analysis.

One of FEM-Design’s key features is its strong interoperability, facilitating seamless collaboration in various design workflows and with various project participants. It ensures smooth integration into the 3D BIM ecosystem (IFC, SAF, Revit, Archicad, Tekla, Allplan, IDEA StatiCa, etc.) and supports traditional CAD workflows with DWG and DXF formats.

Furthermore, FEM-Design supports automated Application Program Interfaces (API) with Grasshopper, Dynamo, XML, XLS and C#.

The unique user-friendly working environment is based on familiar CAD tools that make the model creation and editing the structure both simple and intuitive.

Another one of FEM-Design’s key features is its 3D Bridge module, tailored to analyse pedestrian, road, and railway bridges with moving load automation to calculate traffic load envelopes based on influence lines or surfaces, according to EN 1991-2 standards.

Design Modules in FEM-Design Structural Analysis Software

Discover all the design modules in FEM-Design with the required features for every type of construction material for your projects. Browse among various design and analysis possibilities and choose the perfect mix of FEM-design applications and design modules, to suit your structural engineering needs.

Benefits of using FEM-Design

What do our customers think about us? How are they using FEM-Design Structural Analysis Software? Find out below in some customer testimonials.

As a user of FEM-Design, you are in good company:

How can you try FEM-Design, Structural Analysis Software?

We have made the downloading and installation of FEM-Design as easy and as fast as possible for you, no matter if you are an existing Customer, a Student, or if you are trying out the software for the first time.

Free Trial Version (Commercial Only)

StruSoft now offer a hassle free, 2 week trial, without needing assistance from our support or sales team.

Simply apply through our website using the Trial license option to enjoy a faster response time and the flexibility to evaluate FEM-Design at your own convenience.

You will receive an automated email with everything you need to get started including the software download link, Trial license activation key and video guides.

Please note this option is only for Commercial Trials, for Student/Educational Free Licenses see next section below.

Free Student Version

The FEM-Design Student version gives students free and full access to the software without any analysis or design limitations. We release a new Student version twice a year, so you will need to check the expiry date of your version.

Any Student can apply for the Free Student version of FEM-Design using the Student License form on the website.

You will need to upload a copy of your Student ID.

You will get an automated email and help regarding installation, licensing and support using the program.

Click here for the Free Student Version of FEM-Design!

Why wait? Apply below to download a trial license of FEM-Design and get started on your journey today!

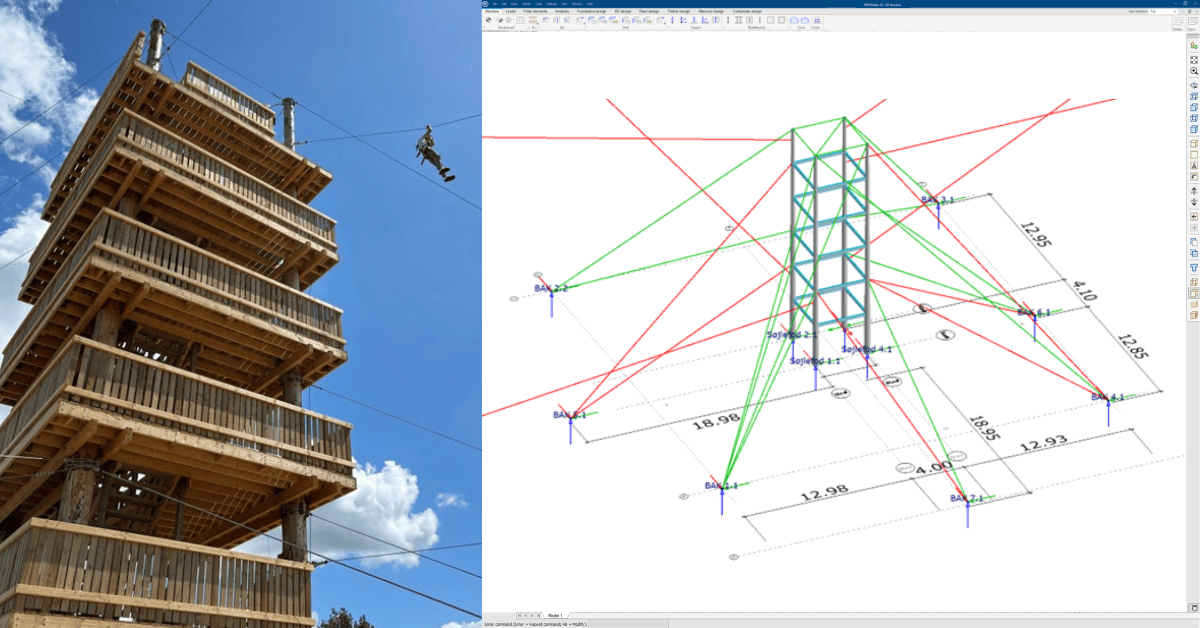

Structural calculation challenges for Fyns Sommerland solved with FEM-Design

Fyns Sommerland is an amusement park in Aarup, Denmark, featuring a 17-zip line complex. The current owners contracted the engineering firm J&P to provide the engineering calculations, drawings, and necessary permits. J&P used FEM-Design, our main structural calculation software, for this project. Project overview: The zip line attraction features [...]

Complex engineering challenges solved with FEM-Design for the Alfa Laval project

The Alfa Laval office building and laboratory project in Stockholm, Sweden, is a testament to the structural complexity and the power of FEM-Design in tackling complex engineering challenges for load analysis and more. As the trusted structural engineering software, FEM-Design played a crucial role in deciphering and resolving the [...]

Calculations performed according to:

Euro Code

Belgian National Annex

British National Annex

Danish National Annex

Dutch National Annex

Estonian National Annex

Finnish National Annex

German National Annex

Hungarian National Annex

Latvian National Annex

Norwegian National Annex

Polish National Annex

Romanian National Annex

Spanish National Annex

Swedish National Annex

Turkish Seismic Code

Languages supported:

English

Finnish

French

Dutch

Hungarian

Polish

FEM-Design Wiki

Full details on FEM-Design Structural Analysis software and all the structural engineering theory and mathematics behind it can be found on the FEM-Design Wiki by clicking here.

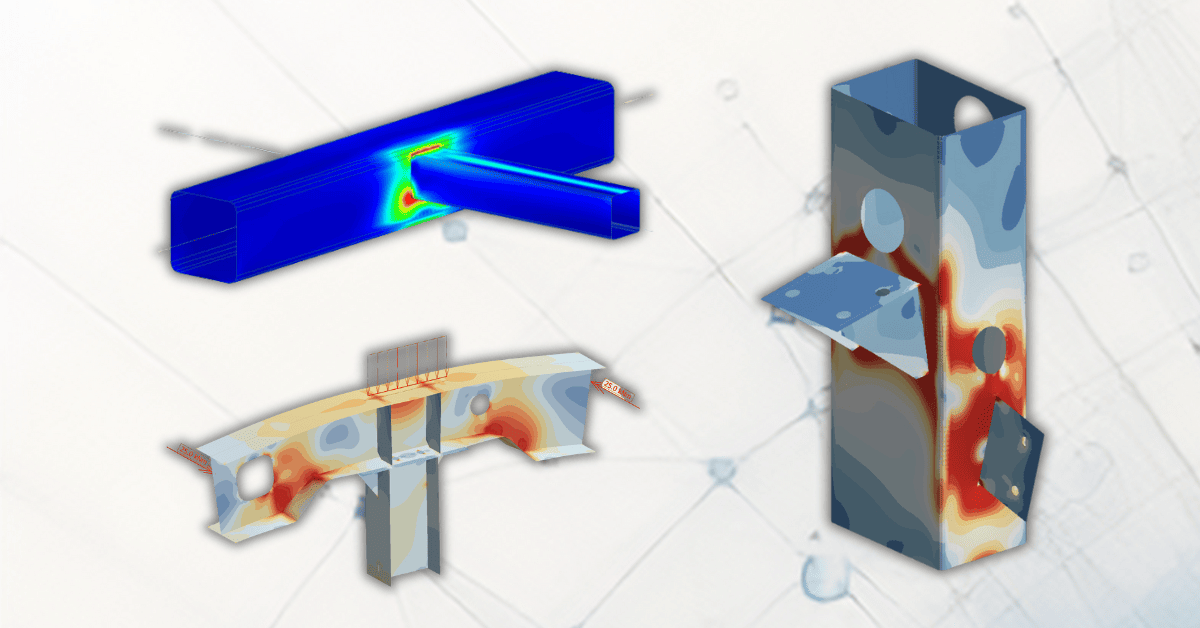

Plastic shell feature in FEM-Design 23 for steel joint analysis

The new Plastic shell feature in FEM-Design 23 is a non-linear material model and is not only available for reinforced concrete but also for [...]

FEM-Climate app is integrated into FEM-Design 23

Our FEM-Climate app has a new home! The functionality is incorporated into FEM-Design 23 and will be further developed and improved within FEM-Design. We [...]

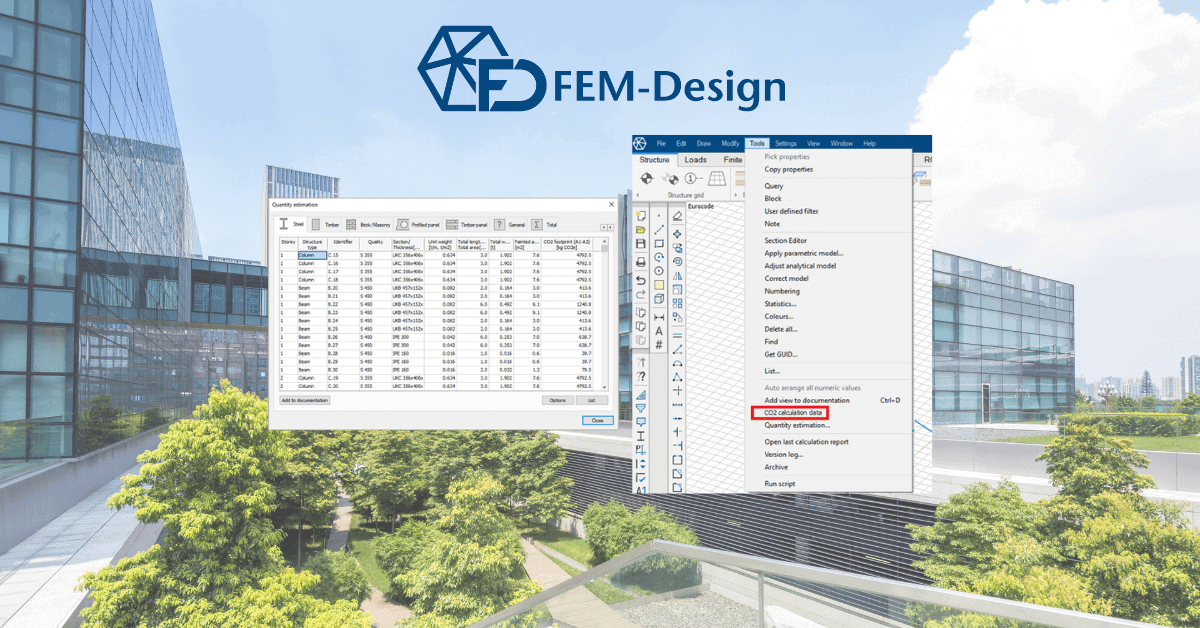

FEM-Design 23 – Greater Efficiency: Save Time, Save Materials

FEM-Design 23 is released and introduces a brand-new 3D Bridge module, a new plastic analysis method, a renewed documentation module, and several significant improvements [...]