With the rise of digitisation; advancements in BIM, many precast businesses have moved to 3D design of their precast concrete projects. However, many factories and project managers are still struggling with planning precast projects in Excel spreadsheets and not taking advantage of the ability to work with specialised software and real-time data for their precast projects.

“Precast is perfectly placed to exploit BIM”, says Matthew Butcher, at British Precast. “Precast firms are working in a controlled factory environment, which is ideal for the principles of design for manufacture and assembly (DfMA).”

Design is a key part of the precast process, of course. But are you able to make the most of your resources (software, personnel, time, and plant) without combining production planning; transport planning, quality control, tracking, project management, and the associated data into one system?

If you’re not fully integrating all parts of the process, then the answer must be no. It may also mean that you’re not best placed to take advantage of what some in the precast industry have termed “Offsite’s Second Coming”.

How To Start?

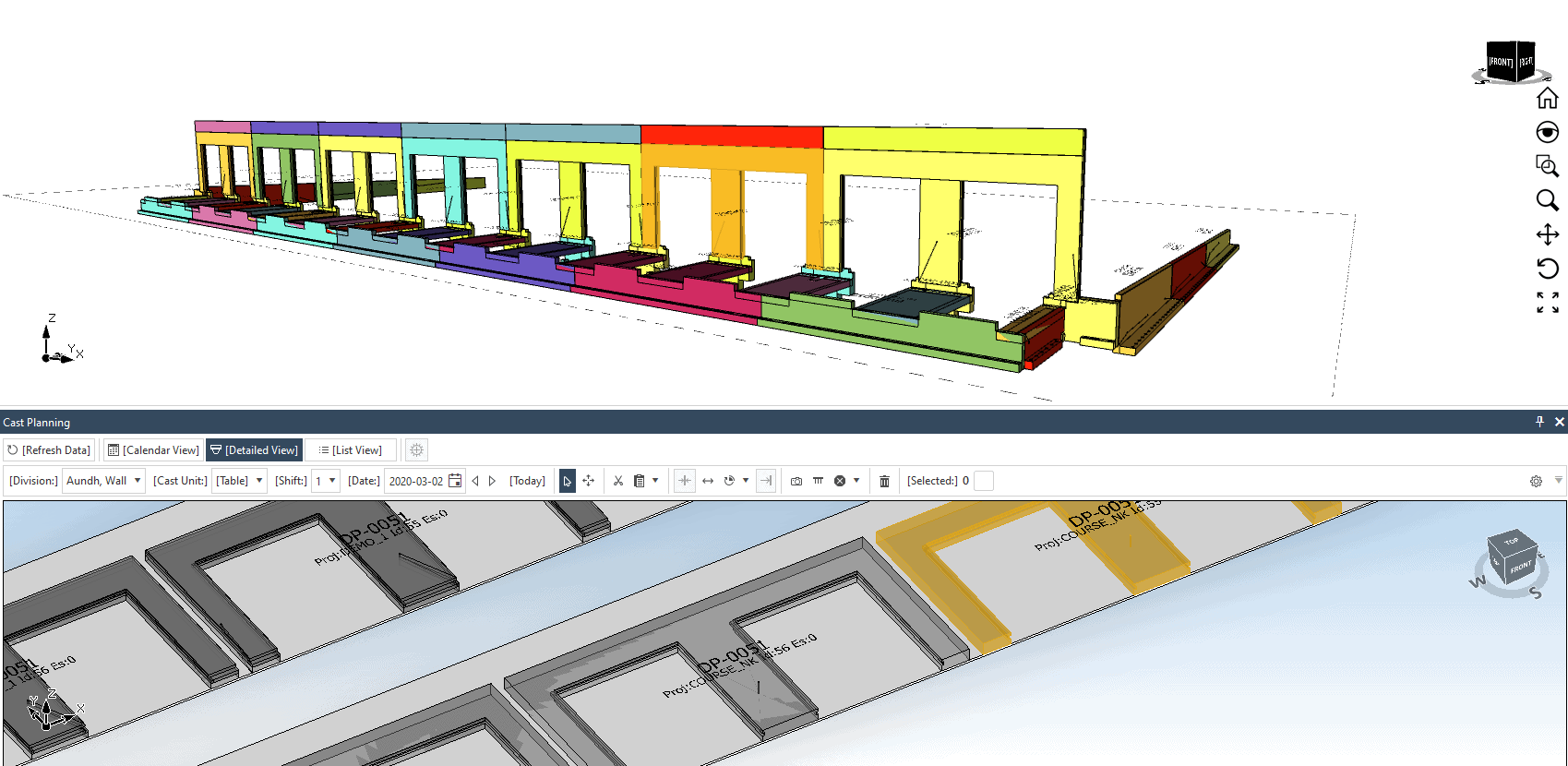

One of StruSoft’s customers in the UK, FP McCann. Have just successfully completed their first successful BIM level 2 project, integrating IMPACT with their existing design software and in-house systems.

By exporting their Tekla® 3D model data into IMPACT’s open database, it’s possible to use this data to drive production; planning, and project management – and it’s this exact solution that helped FP McCann to successfully deliver bespoke precast units for the new logistics hub in Daventry.

Structural precast is a complex and multi-skilled business, not least because it’s a bespoke product competing against traditional on-site methods of construction.

This places huge time pressures on precast businesses; to prepare 3D conceptual designs, calculate accurate costs and delivery schedules. The demands on design, production, and project management resources and workflows are considerable.

These three disciplines: design, production, and projects, are key to the success of your precast project. Therefore, speed of reaction, communication, collaboration, control over logistics, the flow of information, and integration between them is paramount.

Without parallel development of production, project, and logistics workflows, the benefits of the new data-rich 3D models cannot be fully realised. With a lack of industry BIM standards, there is no blueprint to follow.

Watch a Quick Video about Importing Precast Elements from a Tekla 3D Model

One Size Does Not Fit All

Wrapped up in the three pillars of precast is a myriad of systems, processes, and workflows. What’s more, no two precast businesses are the same. There isn’t a “one size fits all” solution.

Because of this, precast business systems and processes have tended to evolve with small incremental improvements over time.

As the first stage, and with the rise of CAD and 3D modelling systems, it makes sense for precast businesses to address their design processes first.

The biggest challenges F.P. McCann faced with the implementation was that processes had to be modified to suit the new software and also the software had to be modified to suit some of the processes.

“We were supported throughout by StruSoft, who developed the Tekla® Base Tools API specifically to support our current design processes and integrate IMPACT with our in-house systems. More efficient planning alone justifies the investment as well as the Element Control to massively reduce errors in the production process.” Dave Norry, F.P. McCann.

Evolution Not Revolution

The true cost of investment in new software and technology can seem to be prohibitive, and it’s easy to think that to fully reap the benefits, you must start from scratch and spend huge sums on equipment, software, and training.

There’s also a consideration for hidden costs such as downtime, or the consequential costs of incorrect use and workarounds that become commonplace when a mixture of systems and workflows are used.

It’s not just about maximising efficiency in design, however. As projects requiring BIM will only increase in number, improving your ability to create information models (IFC) and utilise a common data environment is crucial.

By mapping information into an SQL database you’re then able to integrate the three key areas of precast, using common data and standards to drive continuous improvement in design, production, and project workflows.

Digital data can now be imported into IMPACT from a wide range of sources: Tekla®; Revit; Allplan; CAD; Excel; XML and IFC.

This means everyone – from your own employees to other project stakeholders – can access the same information, in real-time and from anywhere. Not just during the design phase, but throughout project planning, production processes, and beyond.

And perhaps most importantly, this means better outcomes for your projects, your clients, and your bottom line.

Article by Paul Tate, VP | Marketing.