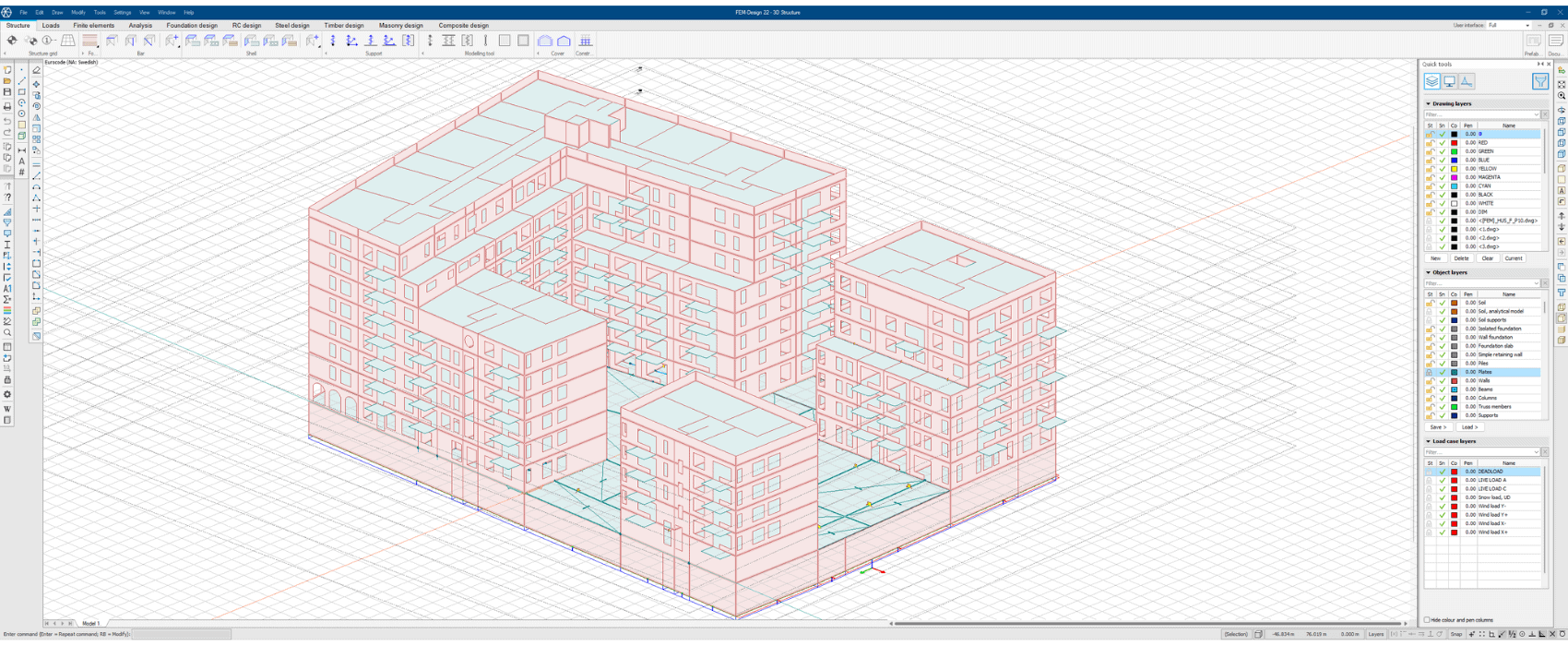

In Stockholm, Zweden, omvat het project Slagsta Strand Kv – 7 de bouw van drie appartementencomplexen. Kritter, een van onze klanten uit Polen, verzorgt het ontwerp met behulp van onze FEM-Design software. De bouw wordt uitgevoerd door Consto AB, met Botvid Holding AB/Nrep als eindklant.

Projectoverzicht

Het project ging van start in mei 2022 en de oplevering staat gepland voor februari 2025. Het betreft een turnkey contract, waarbij de klant een compleet wooncomplex ontvangt met drie huurappartementgebouwen, een ondergrondse parkeergarage met 91 autoparkeerplaatsen en 8 motorplaatsen. Daarnaast zijn er voorzieningen zoals een fietsenstalling en diverse technische ruimten.

Kritter was gedurende iets meer dan een jaar betrokken bij het project: van het voorjaar van 2022 tot augustus 2023.

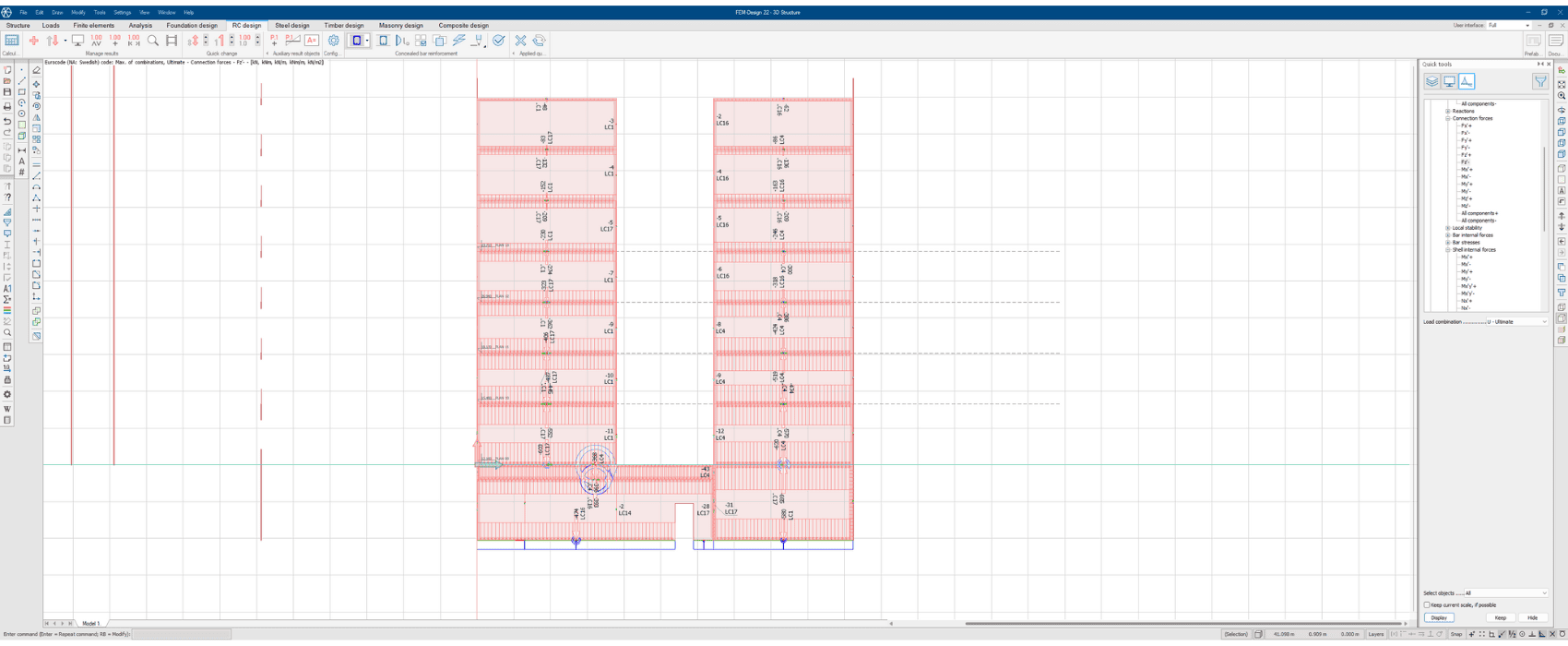

Overview of the completed model in FEM-Design. Image credit: Kritter

Omvang en doelstelling van het project

Het doel was het ontwerpen van alle constructieve betonelementen van de gebouwen en het berekenen van lijnlasten voor de funderingen. In de beginfase moest het team alle lijnlasten, inclusief lasten vanuit wanden en bovenbouw, aanleveren aan de hoofdconstructeur, zodat deze de palenfundering kon ontwerpen. Het proces begon als eerst met de funderingsplaat, gevolgd door de kolommen en liggers boven de parkeergarage. Vervolgens het ontwerp en de verificatie van alle betonelementen zoals keerwanden, binnen- en buitenwanden, kanaalplaatvloeren, balkons (prefab) en andere componenten.

“We werden ingehuurd door het bedrijf dat het contract voor de prefab-elementen had gewonnen. In Zweden is het gebruikelijk dat er een pre-designfase is voorafgaand aan het hoofdontwerp. De eerste stap was het opstellen van het hoofdconstructieve ontwerp, wat enkele maanden in beslag nam. Daarna zijn we gestart met het ontwerpen van de elementen. Het hoofdmodel met de lijnlasten was binnen twee maanden gereed, mede dankzij afstemming met de architect, we hadden namelijk extra steunpunten nodig in de constructie,” vertelt Tomasz Mituś, constructeur bij Kritter.

Uitdagingen:

Een eerste uitdaging was het tijdig aanleveren van lijnlasten voor de funderingen om de grondwerkzaamheden op te starten. Het team moest alle gebouwen doorlopen om te bepalen waar de verticale lasten kwamen. Met behulp van FEM-Design kon men de lasten voor het grootste deel van het project (gebouwen A t/m D) binnen enkele weken afronden en doorsturen.

Later wijzigde de klant de opbouwvolgorde van de gebouwen. In plaats van per verdieping te bouwen (verdieping per verdieping), besloot men eerst alle verdiepingen van gebouw A volledig op te trekken, alvorens te starten met B, C en D. Hierdoor moest het team een stabiliteitsanalyse uitvoeren om krachten op de zijgebouwen en de werking van het statische systeem te beoordelen.

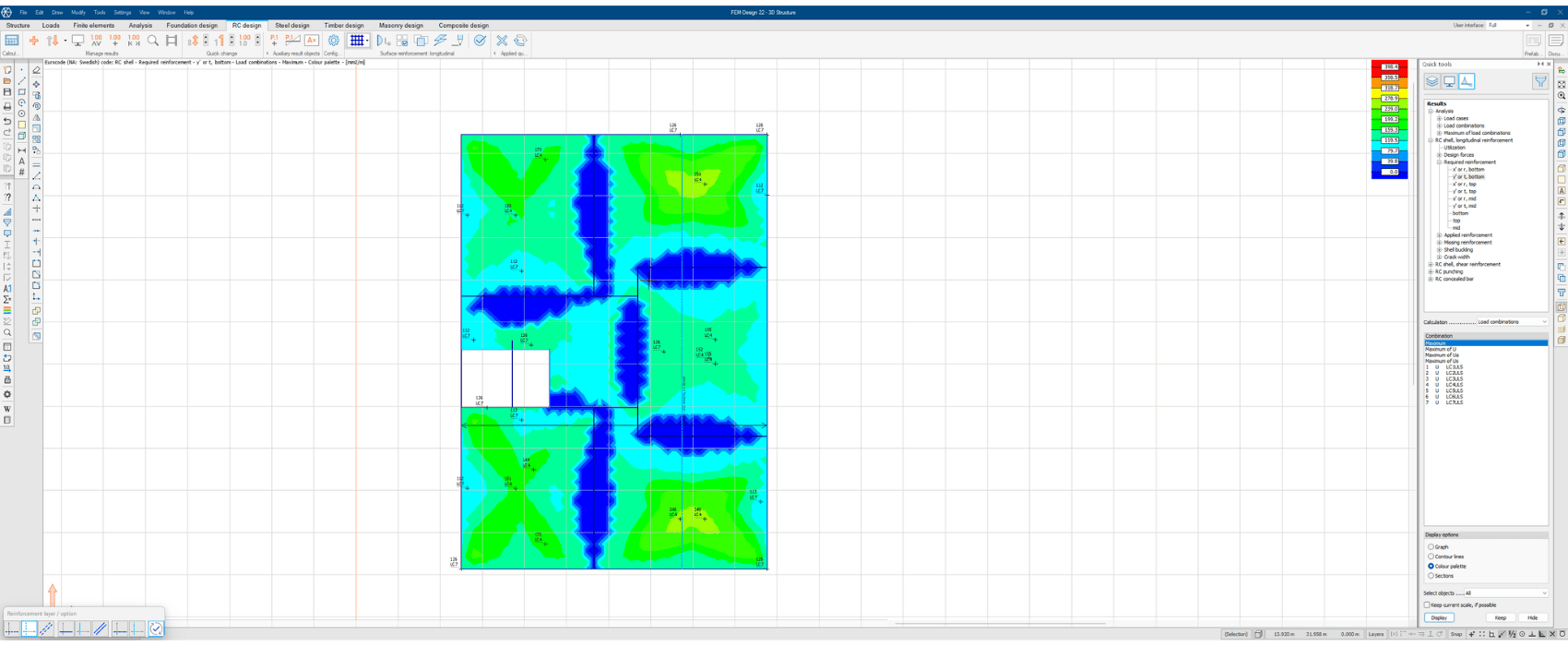

Required reinforcement for the floor system. Image credit: Kritter

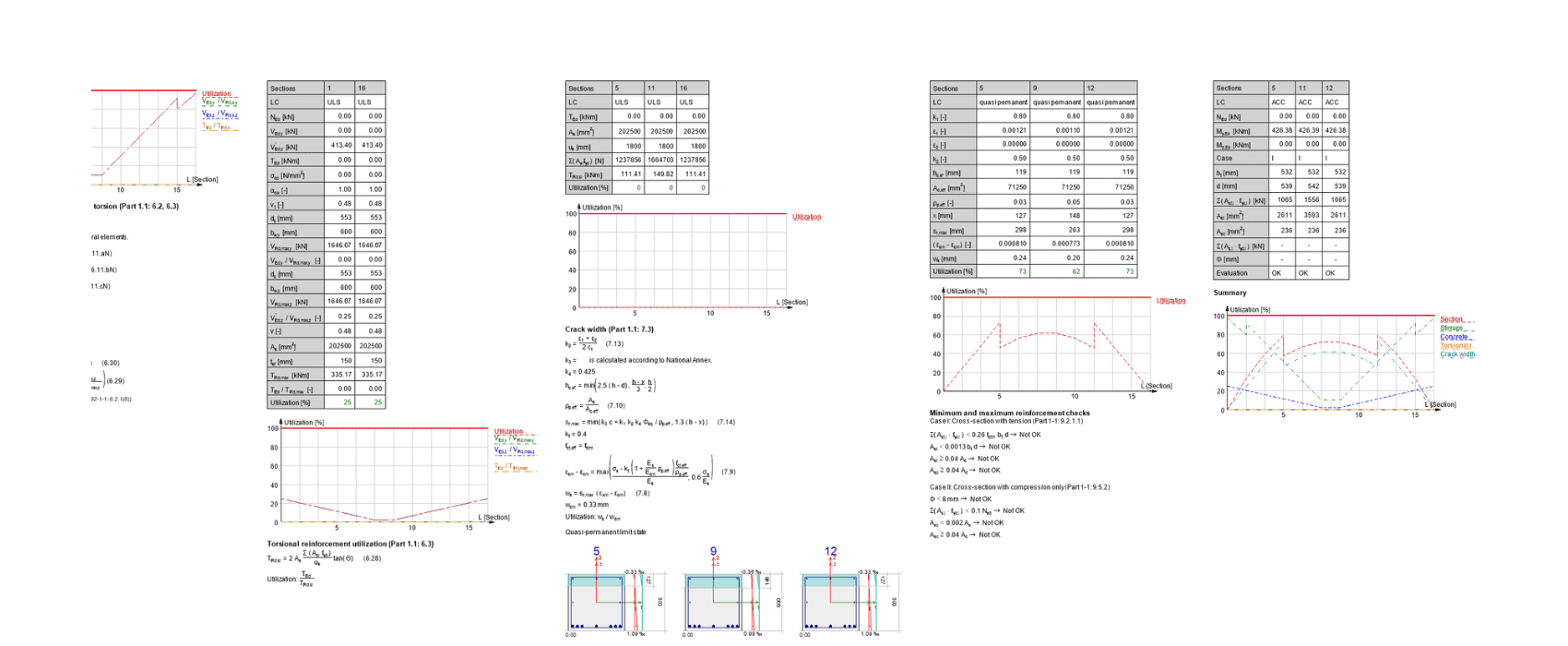

Vanwege het grote aantal liggers in de kelder moest Kritter de belasting nauwkeurig controleren voordat men de eerste verdieping van gebouw A kon bouwen volgens de aangepaste strategie. Dit bleek uitdagend, maar dankzij FEM-Design konden ze het gedrag van de constructie simuleren met slechts één gebouwd deel. De betonontwerpmodule van FEM-Design maakte snelle doorrekening mogelijk.

Summary of a beam in the garage section. Image credit: Kritter

Waarom FEM-Design de voorkeur kreeg voor het ontwerp van betonconstructies

“Ik gebruik FEM-Design al sinds het begin van mijn carrière, zo’n tien jaar geleden. Eerst af en toe, maar de laatste tijd bijna dagelijks – ik ken het programma dus door en door. Ik ben vooral fan van de gebruiksvriendelijkheid en de werkflow,” aldus Tomasz.

De keuze voor FEM-Design was vooral gebaseerd op de snelheid en de intuïtieve gebruikersinterface, ondanks dat er meerdere FEM-pakketten beschikbaar waren.

“FEM-Design is een van de beste programma’s om snel een constructie te modelleren. Bijvoorbeeld: openingen in gevels maken, wisselen tussen oppervlakken, of elementen aanpassen met de rek- of stretchoptie – dat gaat razendsnel. Dat is echt waardevol,” zegt Tomasz.

Voor Kritter vormen FEM-Design en IMPACT de ideale combinatie, vooral vanwege functies die specifiek gericht zijn op de prefabindustrie, zoals het eenvoudig controleren van elementverbindingen.

“Je kunt zien hoe elementen zich gedragen ten opzichte van het analytisch model. Bijvoorbeeld bij kanaalplaatvloeren die je alleen aan de voor- en achterzijde wilt ondersteunen. Dat kan heel makkelijk in FEM-Design, wat voor ons erg handig is,” zegt Tomasz.

Connection forces between the elements. Image credit: Kritter

Bovendien sloot FEM-Design van nature aan bij de projectvereisten van Slagsta Strand Kv – 7.

“We hebben met FEM-Design alle kolommen, liggers, wanden, keerwanden, vloeren en balkons ontworpen. We waren erg te spreken over de functie voor verborgen liggers (concealed bars). Daarmee voeg je een denkbeeldig element toe aan het model, om snel controles uit te voeren zonder een apart model te maken,” aldus Tomasz.

Deze functie maakte het ontwerpen van specifieke elementen veel eenvoudiger. Ook de randverbindingen waren van grote waarde, bijvoorbeeld bij het analyseren van verbindingen en belastingsoverdracht binnen prefab-constructies.

“In FEM-Design is het heel overzichtelijk om de randverbindingen te gebruiken. Je hebt veel opties: randen vrijgeven, stijfheden aanpassen, enzovoort. FEM-Design is voor ons altijd de eerste keuze. Als ik snel een ligger of kolom moet controleren en wapenen, kan dat in maximaal vijf minuten. Mijn ervaring is: FEM-Design is snel én gebruiksvriendelijk,” zegt Tomasz.

Samenwerking met StruSoft

“De ondersteuning is uitstekend, zowel voor IMPACT als FEM-Design. Bij grotere problemen krijgen we vaak binnen een half uur een antwoord – dat is ideaal, want dan lopen we nergens op vast. En als het minder dringend is, sturen we een ticket in en krijgen we ook snel reactie,” sluit Tomasz af.

Over Kritter

Tomasz Mituś is constructeur met specialisatie in gebouwen en COO bij Kritter. Hij werkt al vijf jaar bij het bedrijf en heeft in totaal 10 jaar ervaring in de prefabsector. Tomasz is verantwoordelijk voor het toezicht op alle projecten in Zweden en Polen, met een focus op tekeningen en ontwerpprocessen om kwaliteit en efficiëntie te garanderen.

Kritter is actief in Zweden, Denemarken, het Verenigd Koninkrijk en Polen, en richt zich vooral op het ontwerp van prefab betonnen constructies

Ben je klaar om de kracht van FEM-Design in constructief betonontwerp te ervaren?

FEM-Design is geavanceerde maar toegankelijke software voor constructieve analyse en ontwerp. De software ondersteunt 3D-modellering, ontwerp en eindige-elementenanalyse (EEA) voor constructies in beton, staal, hout, metselwerk, samengestelde materialen en funderingen. Alle berekeningen zijn conform de Eurocode, inclusief nationale bijlagen zoals de Poolse annex, gebruikt bij dit project.

Vraag gerust een gratis proefversie aan om te ontdekken of FEM-Design bij jou past. Of bekijk de videotutorials op ons YouTube kanaal– een uitstekend startpunt.